Preparation process of chromium glucosaminic acid and use thereof

A technology of glucosamine and glucosamine, which is applied in the field of chromium glucosamine, and can solve the problems of obtaining a single purified product, such as complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

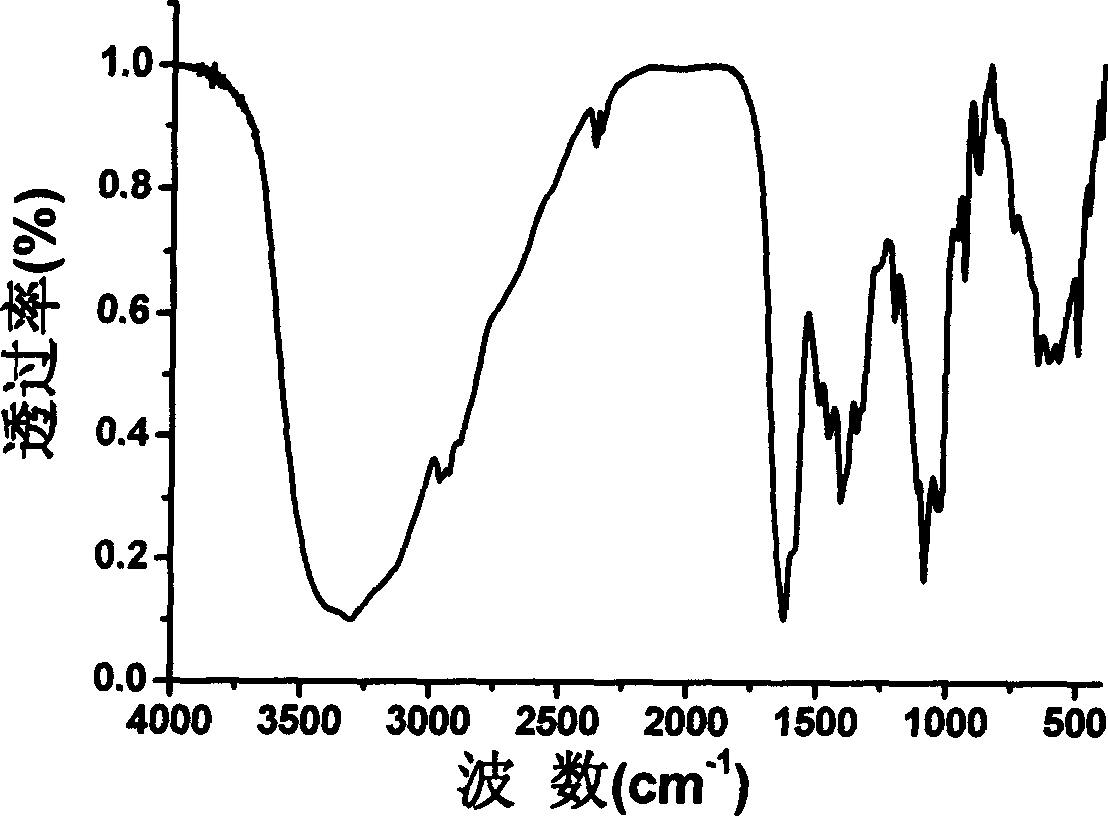

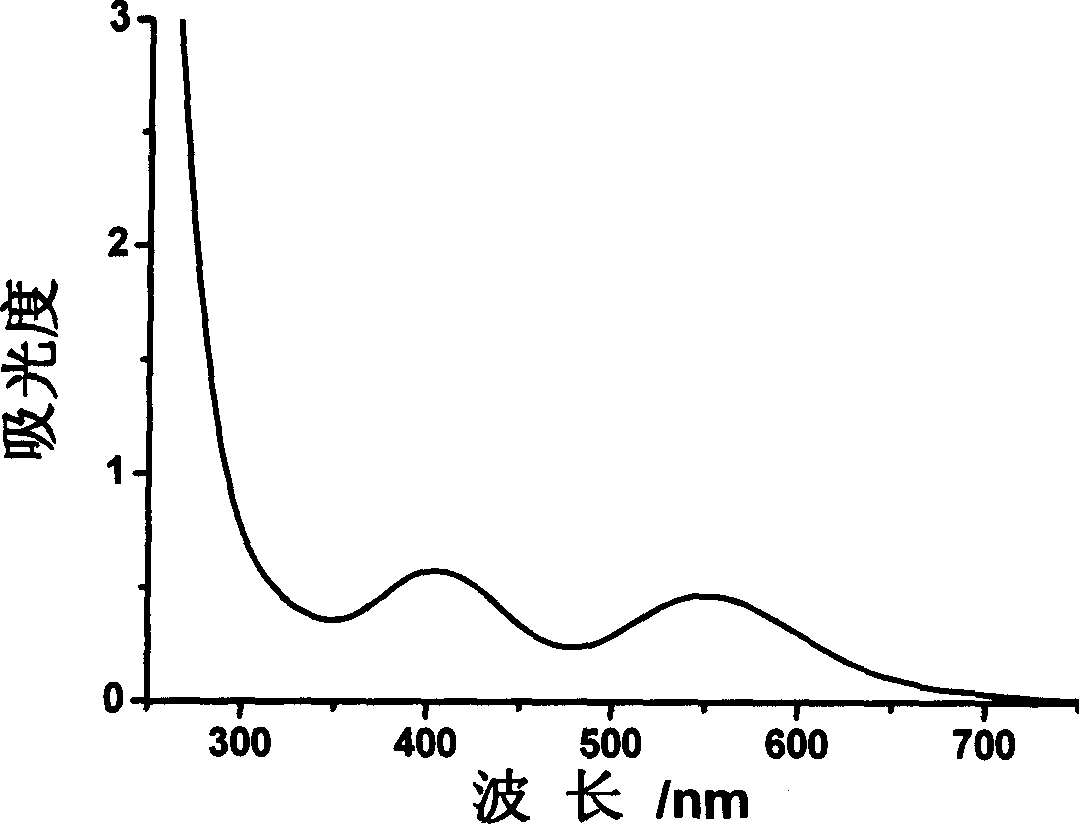

[0038] Embodiment 1 Synthesis of chromium trisamine gluconate (III)

[0039] 1.17 g (6 mmol) of glucosamine acid was dissolved in 12 ml of water, and 6 ml containing 0.5 g of Cr 2 (SO 4 ) 3 ·6H 2 O (1 mmol) in water, stirring and heating the solution to 45°C. In 1.5 hours, slowly add 30 ml containing 0.514 g Ba(OH) 2 (3 mmol) solution. Precipitation was formed immediately, and the solution color changed from green to purple. After continuing to stir for half an hour, the precipitate was filtered off, and the solution was stirred for another 3 hours. The solution was concentrated to 2 / 3 of the original volume, and methanol was added to precipitate a precipitate. The precipitate was filtered off and washed with methanol and ether. Dissolve with the least amount of water, and then add five times the amount of methanol for recrystallization. The precipitate was filtered off and dried in a phosphorus pentoxide dryer. Yield 60%. Elemental analysis, Cr (C 6 h 12 NO 6 ) ...

Embodiment 2

[0040] Embodiment 2 Synthesis of chromium trisamine gluconate (III)

[0041] The amount of reagent used is the same as in Example 1, and the order of addition is adjusted to: first mix glucosamine and barium hydroxide Ba(OH) 2 After stirring the solution at 45°C, add chromium sulfate Cr 2 (SO 4 ) 3 ·6H 2 O aqueous solution. Subsequent processing is carried out with embodiment 1. Combine spectral analysis through elemental analysis, identical with embodiment 1 product.

Embodiment 3

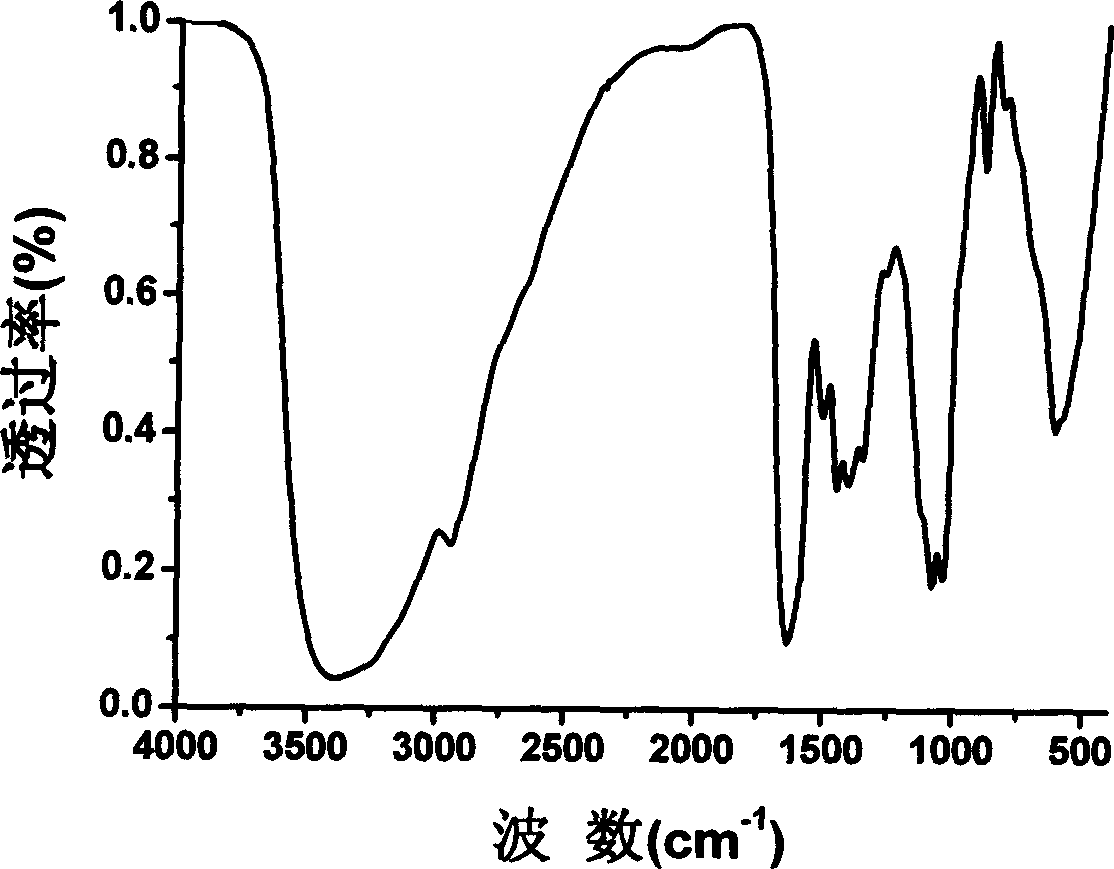

[0042] Example 3 Trisamine gluconate dichromium (III) hydrochloride

[0043] 1.960 g (10 mmol) of glucosamine acid was dissolved in 20 ml of water, and 15 ml containing 1.251 g of Cr 2 (SO 4 ) 3 ·6H 2 O (2.5 mmol) in water, stirring and heating the solution to 45°C. In 1.5 hours, slowly add 50 ml containing 0.857 g Ba(OH) 2 (5 mmol) and 0.611 g of BaCl 2 (2.5 mmol) solution. Precipitation was formed immediately, and the solution color changed from green to purple. After continuing to stir for half an hour, the precipitate was filtered off, and the solution was stirred for another 3 hours. The solution was concentrated to 2 / 3 of the original volume, and methanol was added to precipitate a precipitate. The precipitate was filtered off and washed with methanol and ether. Dissolve with the least amount of water, and then add five times the amount of methanol for recrystallization. Yield: 35%. Elemental Analysis: Cr 2 (C 6 hi 2 NO 6 ) 3 Cl 3 Theoretical value: C 27....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com