Method for preparing LiNi1-XCOXO2 of anode material of lithium ion secondary battery

A technology of lithium nickel cobalt oxide and secondary battery, which is applied to the preparation of positive electrode materials for lithium ion secondary batteries and the preparation of lithium nickel cobalt oxide LiNi1-xCoxO2, can solve the problems of resource shortage, capacity decay, and fast decay speed, etc. Achieve the effect of shortening the roasting time, stabilizing the cycle performance and realizing the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

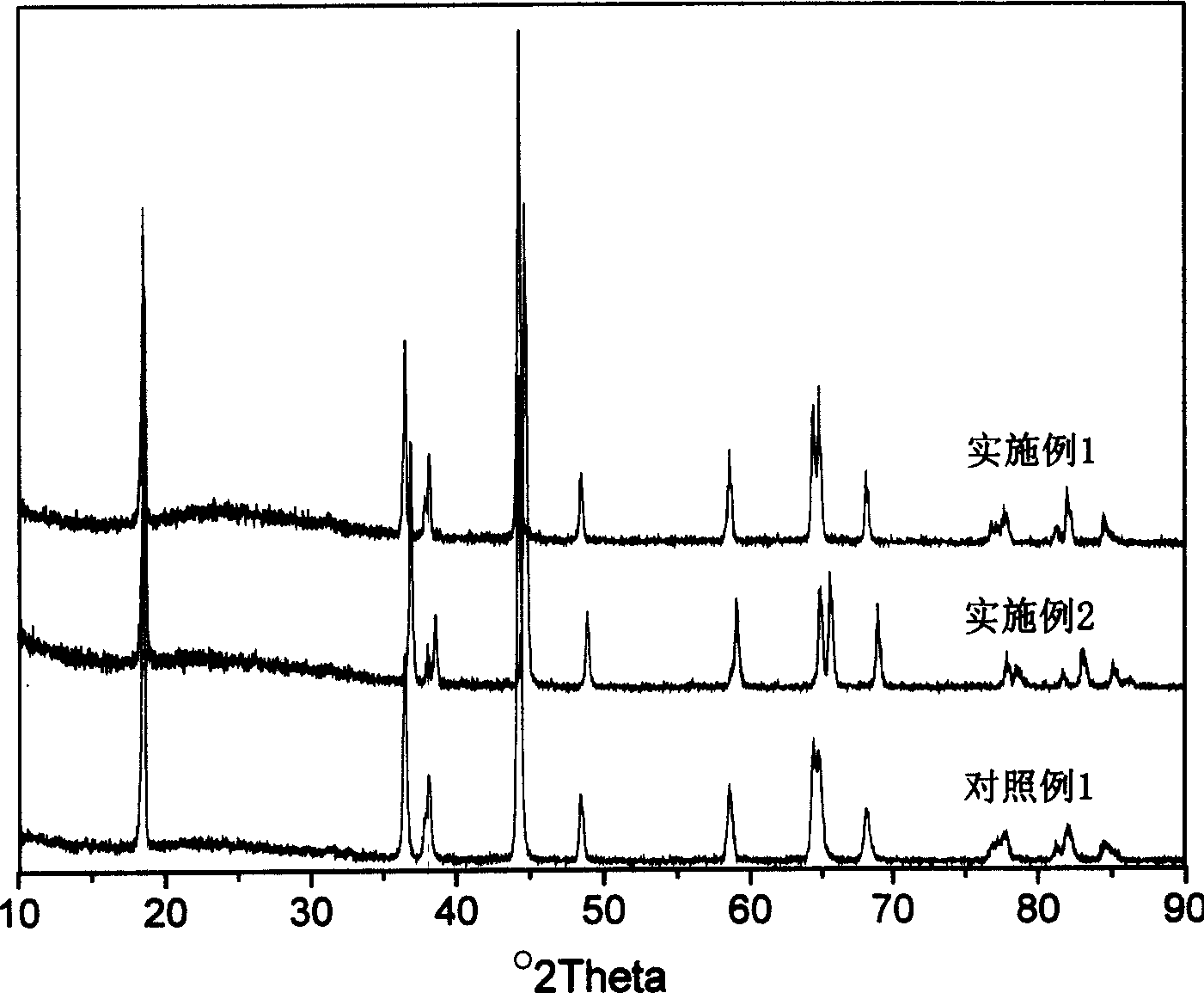

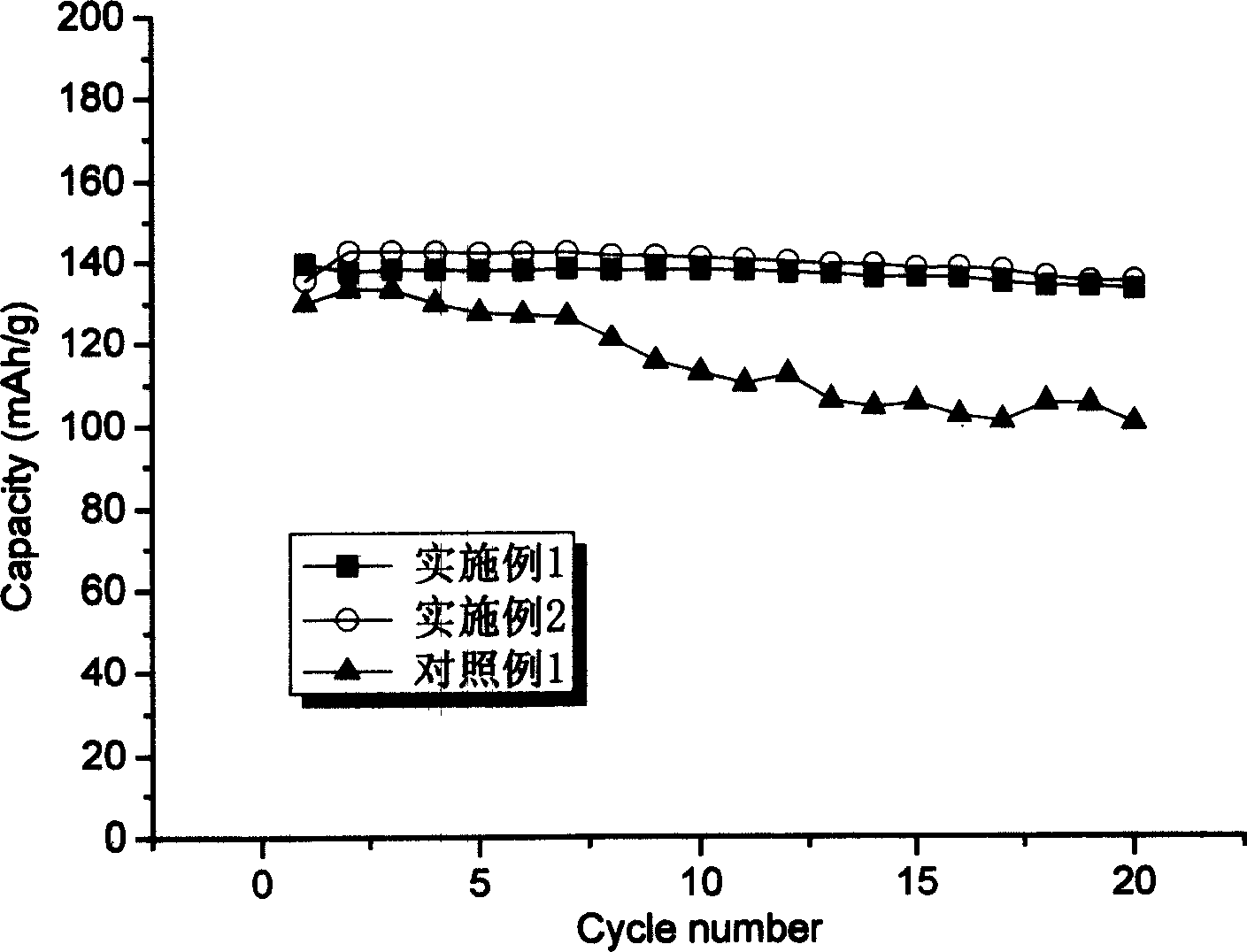

Embodiment 1

[0015] Dissolve 0.08 moles of nickel nitrate hexahydrate and 0.02 moles of cobalt nitrate hexahydrate in an appropriate amount of distilled water, stir, and keep the solution at a constant temperature in a water bath at 90°C. The dosage of sodium hydroxide and ammonium persulfate solution is suitable to completely co-precipitate and oxidize cobalt and nickel. The reaction system was allowed to stand overnight to complete the reaction, the obtained precipitate was separated by suction filtration, and the precipitate was washed with distilled water, so that the precipitate did not contain impurity ions such as sulfate radicals, and the washed precipitate was dried at 80 ° C to obtain Ni 1-x Co x OOH powder. Put this powder and lithium hydroxide monohydrate in a molar ratio of 1:1 in an agate mortar, add an appropriate amount of ethanol, and grind until the system becomes a rheological phase. The temperature was raised to 500°C, kept at a constant temperature for 10 hours, then...

Embodiment 2

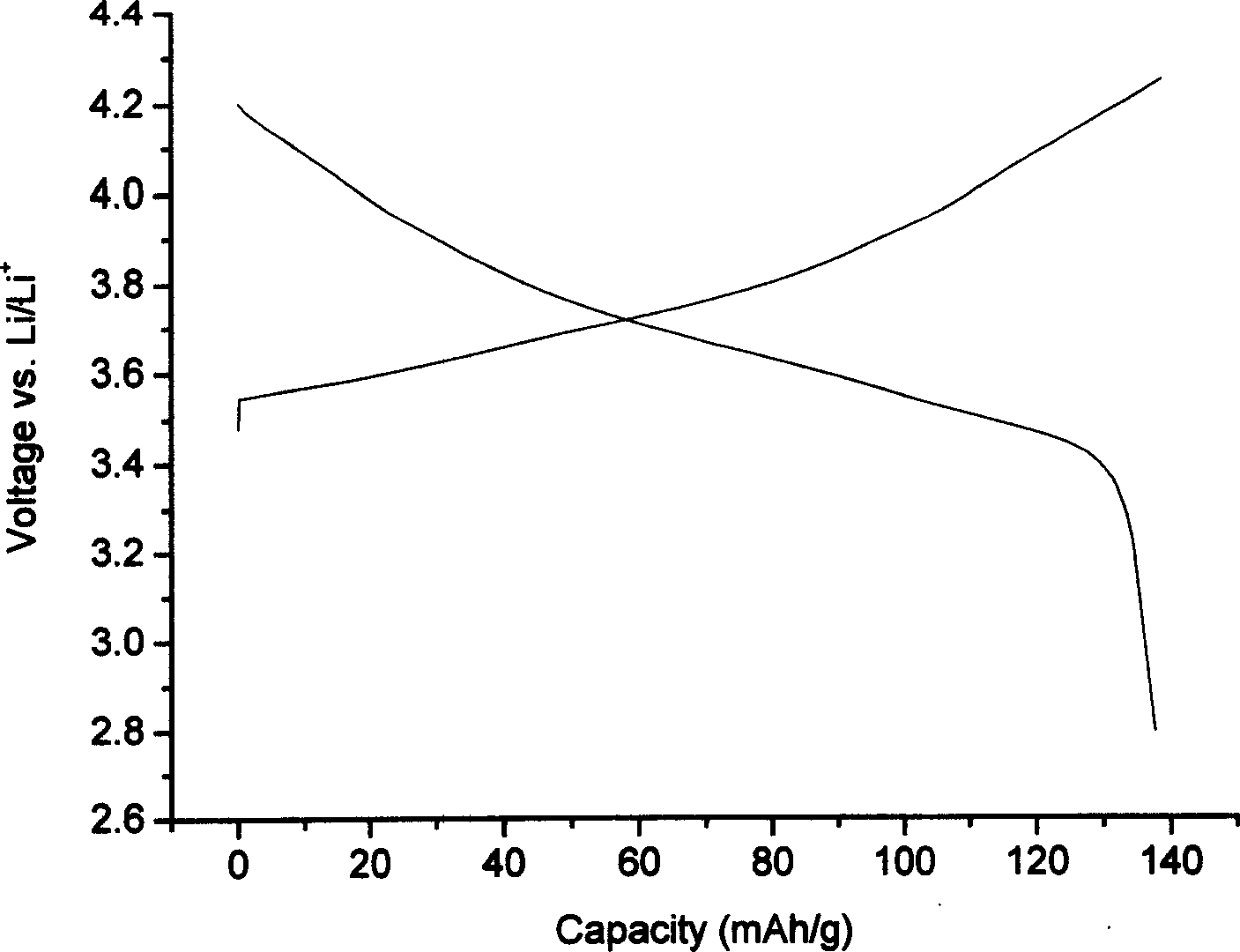

[0017] The synthesis step is the same as in Example 1, except that the consumption of nickel nitrate hexahydrate is changed to 0.05 moles, the consumption of cobalt nitrate hexahydrate is changed to 0.05 moles, and the product is LiNi 0.5 Co 0.5 O 2 . The first discharge capacity of the assembled battery at 0.5C rate charge and discharge is 135mAhg -1 , the maximum discharge capacity is 142mAhg -1 , the discharge platform voltage is 3.6V, and the battery cycle stability is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com