Decompression tower bottom coke inhibiting device and its uses

A decompression tower and coke blocking technology, applied in the field of distillation tower internals, can solve the problems of affecting the production of the device, high local temperature, dead angle of liquid flow, etc., and achieve the effect of enhancing the turbulent effect, avoiding the formation and avoiding the coke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

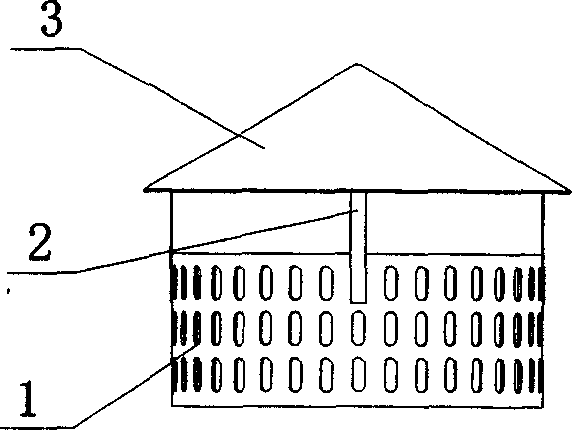

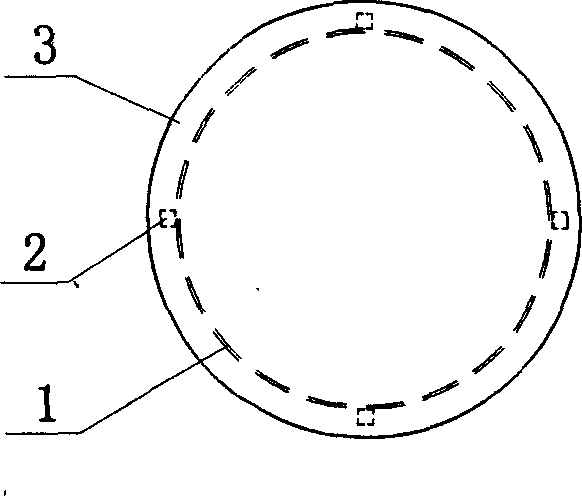

[0026] Such as Figure 1a and Figure 1b As shown, the side wall of the coke blocking device is a cylindrical porous baffle 1, and the diameter of the cylinder is equal to or slightly larger than the inner diameter of the extraction kettle. There are multiple round holes or oblong holes on the side wall, and a cone is added to the top of the porous baffle. Shaped liquid blocking cap 3, the two are connected by supporting ribs 2, and the liquid blocking cap 3 guides the liquid falling from above to the annular space formed by the coke blocking device and the tower wall.

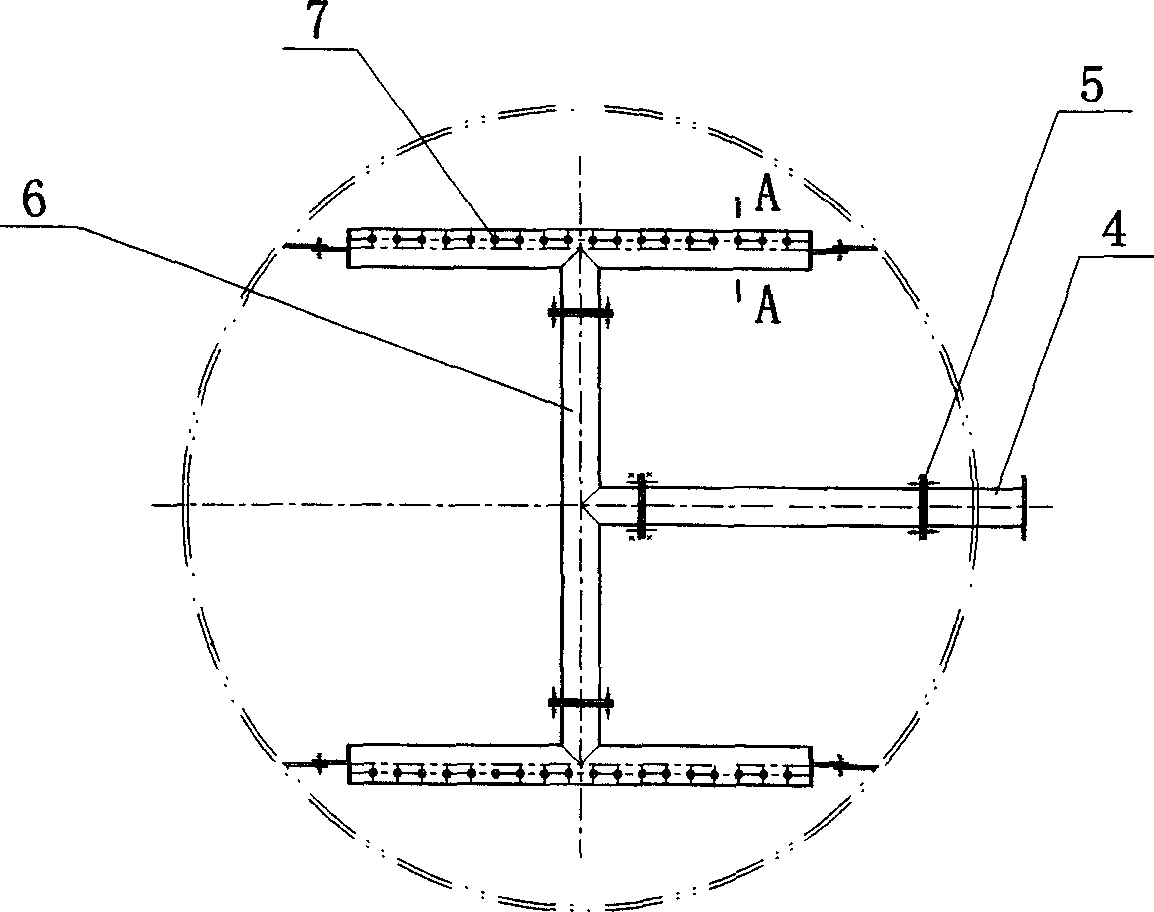

[0027] Such as figure 2 As shown, the quenching oil distribution pipe 6 is connected to the quenching oil inlet pipe 4 through the flange 5, and the upper double overflow tray is set as an "H" branch pipe or the single overflow tray is set as a "T" branch pipe. The branch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com