Phospholipid modified acrylon nano fiber composite film and its preparation and immobilized enzyme thereof

A technology of nanofibers and immobilized enzymes, applied in the direction of fixing on/in organic carriers, wet spinning, etc., can solve the problems of reduced enzyme activity, low enzyme loading and catalytic efficiency, and difficult recovery of immobilized enzyme carrier materials and other issues to achieve the effect of sufficient sources, improved biological activity and stability, and easy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

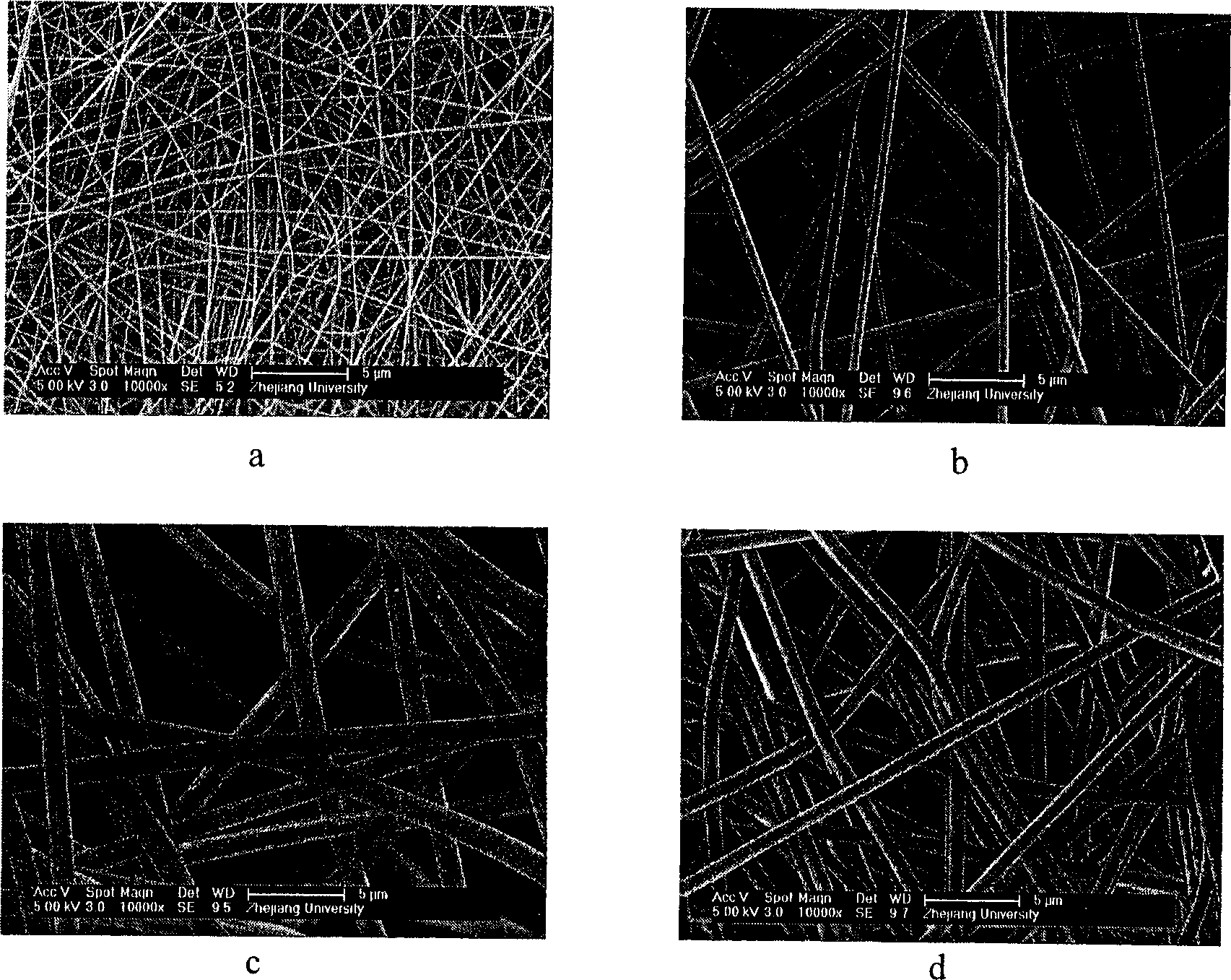

[0034] 4wt% of acrylonitrile / 2-methacryloyloxy-ethyl-phosphatidylcholine copolymer (viscosity-average molecular weight is 80,000, 2-methacryloyloxy-ethyl-phosphatidylcholine content is 1.8 mol%) was dissolved in dimethylformamide, mechanically stirred at 60°C, and completely dissolved to form a homogeneous, transparent, viscous solution; defoaming and removal of impurities to obtain spinning solution, which was added to the injection Connect the spinneret to the spinneret, connect the spinneret to a high-voltage power supply, the distance between the spinneret and the acceptor is about 15 cm, the flow rate of the spinneret spinning solution is 0.2mL / h, and the voltage is 10 k and carry out electrospinning to obtain a phospholipid-modified acrylic nanofiber composite membrane carrier material with a diameter of 60-90 nanometers.

example 2

[0036] 6 wt% of acrylonitrile / 2-methacryloyloxy-ethyl-phosphatidylcholine copolymer (viscosity average molecular weight is 80,000, 2-methacryloyloxy-ethyl-phosphatidylcholine content is 1.8 mol%) was dissolved in dimethylformamide, mechanically stirred at 60°C, and completely dissolved to form a homogeneous, transparent, viscous solution; defoaming and removal of impurities to obtain spinning solution, which was added to the injection Connect the spinneret to the spinneret, connect the spinneret to a high-voltage power supply, the distance between the spinneret and the acceptor is about 15 cm, the flow rate of the spinneret spinning solution is 0.5mL / h, and the voltage is 10 k Volts, electrospinning is carried out to obtain a phospholipid-modified acrylic nanofiber composite membrane carrier material with a diameter of 100-150 nanometers.

example 3

[0038] 4wt% acrylonitrile / 2-methacryloyloxy-ethyl-phosphatidylcholine copolymer (viscosity average molecular weight is 76,000, 2-methacryloyloxy-ethyl-phosphatidylcholine content is 4.9 mol%) was dissolved in dimethylformamide, mechanically stirred at 60°C, and completely dissolved to form a homogeneous, transparent, viscous solution; defoaming and removal of impurities to obtain spinning solution, which was added to the injection Connect the spinneret to the spinneret, connect the spinneret to a high-voltage power supply, the distance between the spinneret and the acceptor is about 15 cm, the flow rate of the spinneret spinning solution is 0.2mL / h, and the voltage is 10 k and carry out electrospinning to obtain a phospholipid modified acrylic nanofiber composite membrane carrier material with a diameter of 50-80 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com