Tensioning device for rope saw machine

A technology of tensioning device and wire saw machine, which is applied in the direction of stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problems that the tensioning device is not suitable for application, the force of the shaft and the bearing is large, and the cutting cannot be performed, etc., to achieve Simplified base structure and hydraulic power source, easy manufacturing and debugging, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

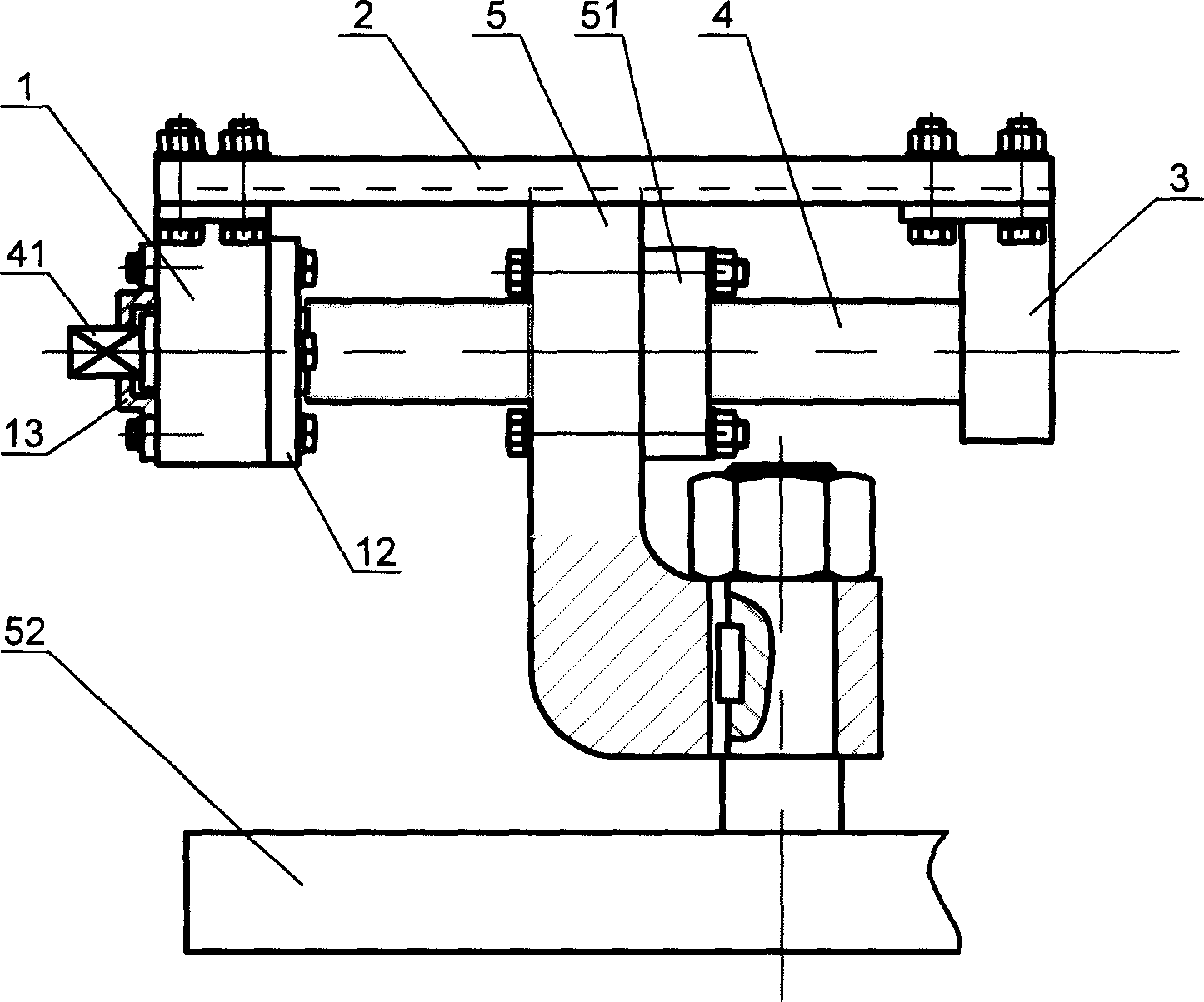

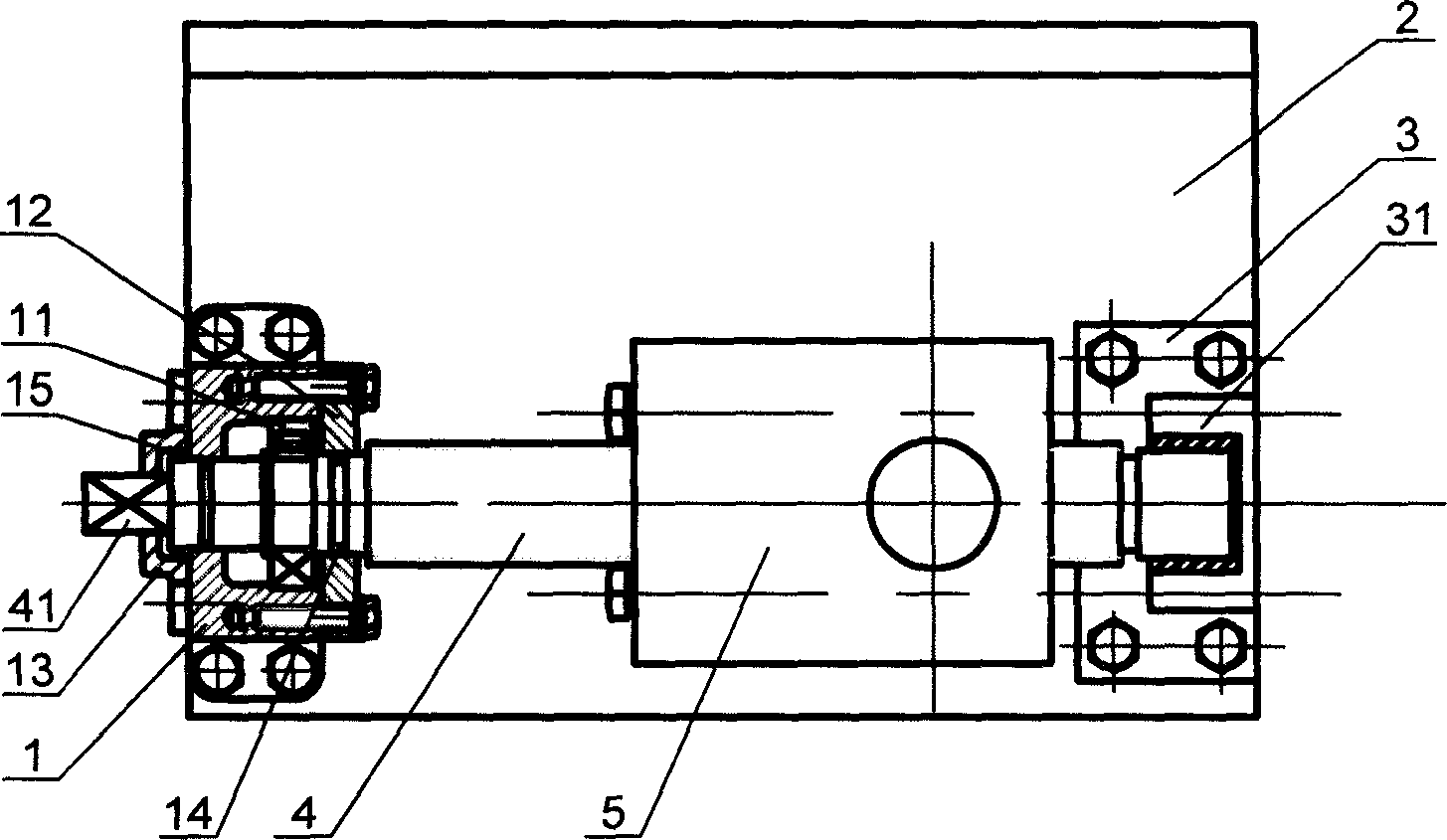

[0016] Such as figure 1 , figure 2 Shown, for the tensioning device of a kind of wire saw machine provided by the present invention, it includes:

[0017] A rolling bearing seat 1, which is arranged on the bottom plate 2 of the tensioned saw bow, and a rolling bearing 11 is arranged in the rolling bearing seat 1;

[0018] A sliding bearing seat 3, which is arranged on the bottom plate 2 of the tensioned saw bow, and a sliding bearing 31 is arranged in the sliding bearing seat 3;

[0019] A threaded screw 4, one end of which is set in the sliding bearing 31, and the other end passes through the rolling bearing 11 and extends out of the rolling bearing seat 1;

[0020] A tensioning wheel frame 5, which is sleeved and connected to the lead screw 4, is connected and driven by a nut 51 between the tensioning wheel frame 5 and the leading screw 4; The chute 21, the top of the tensioning wheel frame 5 is slidingly arranged in the chute 21; in addition, the bottom of the tensionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com