Method for reliable contact of probe and nano-electrode of phase transformation memory device unit

A phase-change memory and nano-electrode technology, which is applied in static memory, instruments, and measuring electronics, can solve problems such as inability to perform electrical performance, high contact pressure, and deformation of nano-probes, and achieve reliable contact. The method is practical and convenient , the effect of great practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

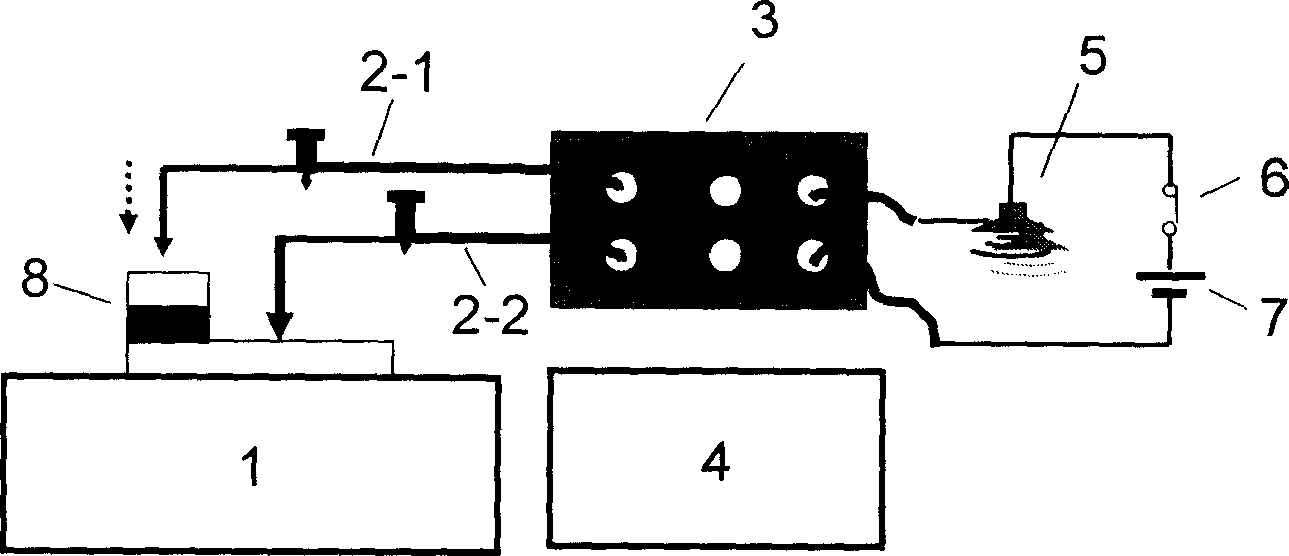

[0038] Embodiment 1: Referring to Fig. 1, the main preparation process and testing method of the sample are as follows:

[0039] (1) The substrate is 500nm thick SiO 2 For the Si sheet of the dielectric film, first use the magnetron sputtering method to grow an 80nm thick Ti / TiN transition layer, and then sputter to prepare a 100nm thick W as the bottom electrode;

[0040] (2) Magnetron sputtering phase change material GeSbTe, the thickness is about 80nm, the background vacuum is 3×10 -6 Torr, the sputtering vacuum is 0.08Pa, and the power is 100W.

[0041] (3) Put the prepared sample on the sample stage shown in Figure 1, adjust the probes, one is in contact with the lower electrode, the other is suspended above the upper electrode, and the two probes are connected to the circuit of the alarm device. Close the switch, slowly adjust the knob, so that the probe above the upper electrode slowly drops, when the alarm alarms, stop adjusting, and turn off the alarm switch.

[00...

Embodiment 2

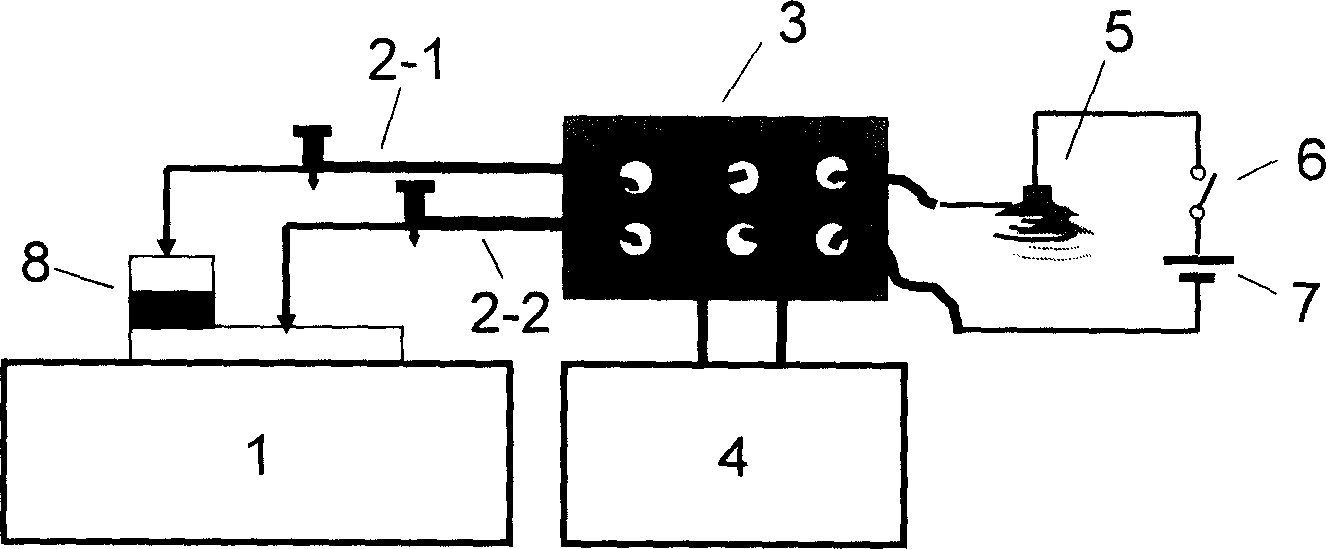

[0044] Embodiment 2: see figure 2 , sample preparation is the same as embodiment one, and the testing method of sample is as follows:

[0045] (1) Open the inflation valve of the vacuum system, fill the sealed chamber with air, open the sealing cover, and put the sample into figure 2 In the cavity shown, adjust the sample stage so that the upper and lower probes are respectively aligned with the upper and lower electrodes of the sample;

[0046] (2) Close the inflatable valve, cover the sealing cover, vacuumize the mechanical pump, adjust the probes, one is in contact with the lower electrode, the other is suspended above the upper electrode, and the two probes are connected to the circuit of the alarm device. Turn on the switch, slowly adjust the knob to make the probe above the upper electrode drop slowly, when the alarm alarms, stop adjusting and turn off the alarm switch.

[0047] (3) Feed liquid nitrogen from the refrigerant inlet, observe the reading of the digital vol...

Embodiment 3

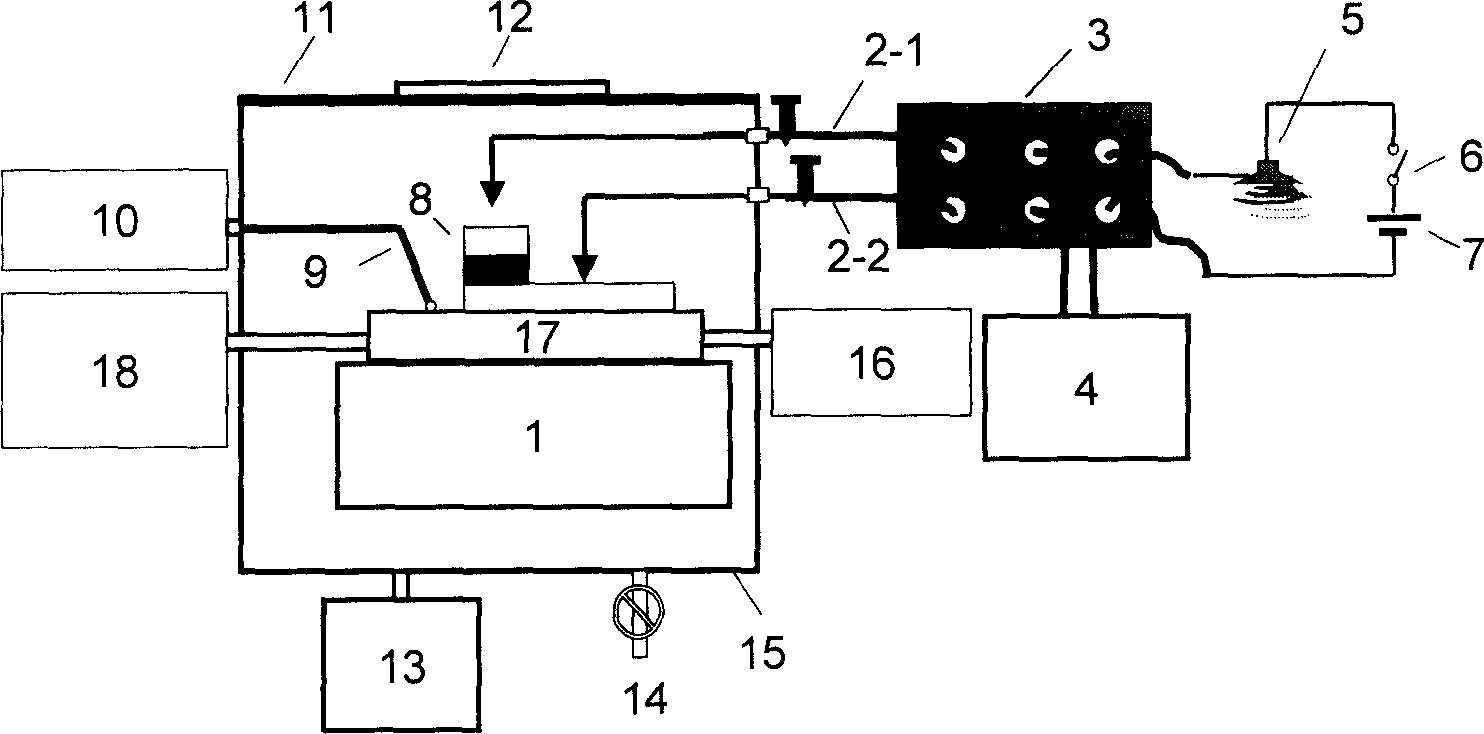

[0050] Embodiment 3: see image 3 , sample preparation is the same as embodiment one, and the testing method of sample is as follows:

[0051] (1) Open the inflation valve of the vacuum system, fill the sealed chamber with air, open the sealing cover, and put the sample into image 3 In the cavity shown, adjust the sample stage so that the upper and lower probes are respectively aligned with the upper and lower electrodes of the sample;

[0052] (2) Close the inflation valve, cover the sealing cover, vacuumize the mechanical pump, adjust the probes, one is in contact with the lower electrode, and the other is suspended above the upper electrode, and the two probes are connected to the circuit of the alarm device. On the switch, adjust the knob slowly to make the probe above the upper electrode drop slowly. When the alarm alarms, stop adjusting and turn off the alarm switch;

[0053] (3) Heat the hot plate through the heating control system, and observe the reading of the dig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com