Prepn. method of low toxicity CdSe/ZnSe nucleocapsid quantal-points

A technology of core-shell quantum dots and low toxicity, which is applied in the preparation of semiconductor CdSe/ZnSe core-shell nanomaterials and the field of fluorescent nanomaterials. It can solve the problems of quantum dot instability, large surface defects, and impact on safety, and achieve low prices. , good monodispersity, and the effect of raw material safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

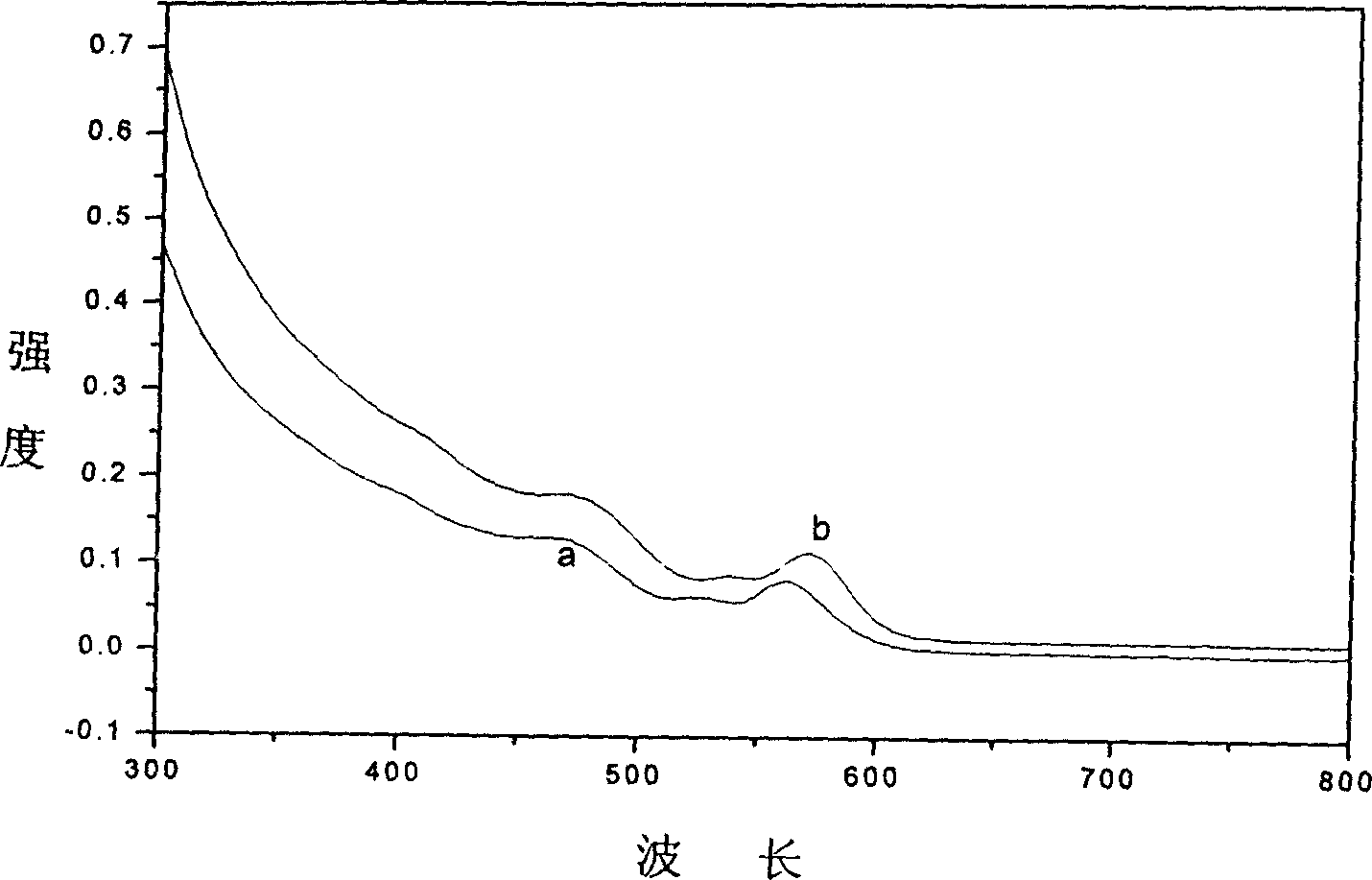

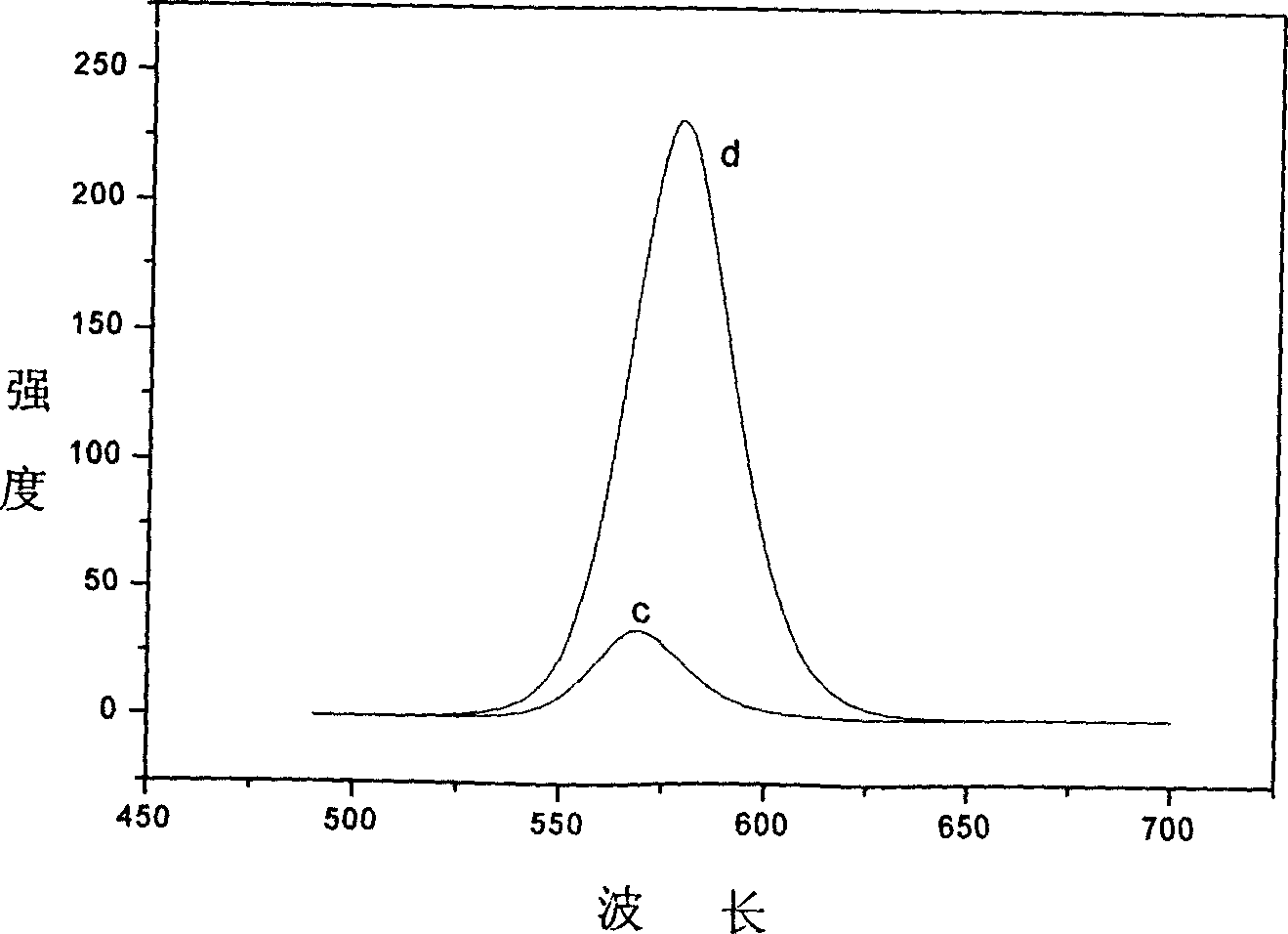

Image

Examples

Embodiment

[0016] 1. Weigh 0.079g of selenium powder with a weight percentage of 3.33%, put it into a penicillin bottle, add 1ml tri-n-octylphosphine, 33.55% by weight, and 2ml octadecene, 63.12% by weight, after sealing Ultrasonic for about 30 minutes to dissolve all the selenium powder to prepare a selenium stock solution.

[0017] 2. Weigh 0.318 g of zinc stearate with a weight percentage of 8.4%, put it into a penicillin bottle, add 4 ml of toluene, and keep it in a 60°C water bath for 10 minutes to prepare a zinc stock solution.

[0018] 3. Weighing CdO is 0.0256g, weight percentage is 0.6%, stearic acid is 0.228g, weight percentage is 5.37%, and 2.4ml octadecene, weight percentage is 44.6%, put into the three-necked bottle, magnetic force Fill with nitrogen while stirring, heat to 200° C. with a heating mantle and hold for 5 minutes until the solution is a colorless and transparent solution; then naturally cool down to room temperature. Preparation of cadmium precursors. Add 1.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com