Method of improving gas separation film penetration instrument

A technology of gas separation membranes and permeameters, which is applied in the field of chemical engineering and can solve problems affecting the accuracy of membrane permeability measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

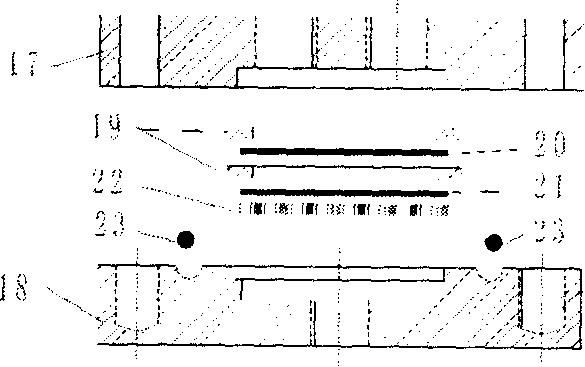

[0019] exist figure 2 In the process, stick the upper and lower sides of the flat membrane 20 on the ring-shaped thin aluminum tape 19 respectively, place a layer of filter paper on the porous backing plate 22 and fix it in the middle depression of the lower cover 18 of the membrane pool with glue, and put the O-shaped sealing gasket 23. Fix the upper cover 17 of the membrane pool and the lower cover 18 of the membrane pool with hexagonal screws.

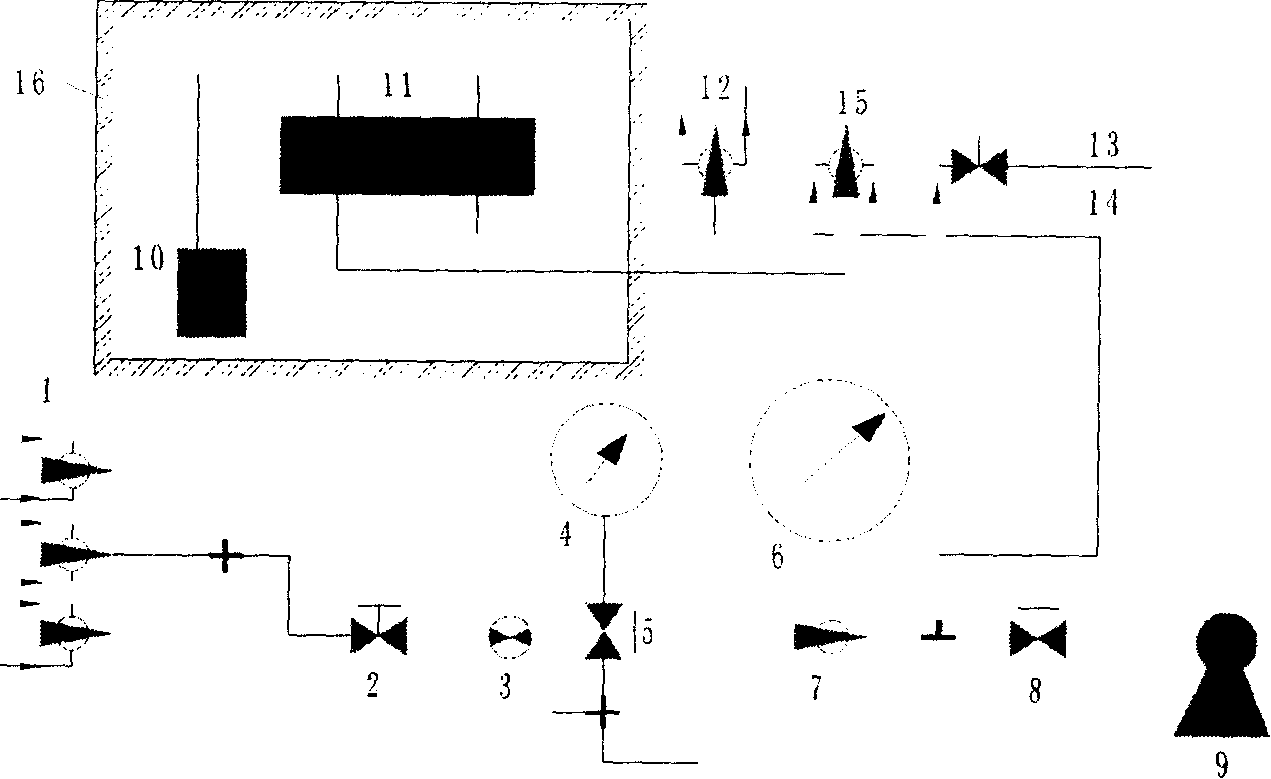

[0020] exist figure 1 in, will figure 2 The membrane pool in is connected to the gas path 11 position with the temperature control box, and the temperature of the temperature control box 16 is set. Close the intake valve 1, three-way valve 7 and 15, open the valve 8, and turn the valve 15 to vacuumize. In order to prevent the film from being broken (inorganic film, such as carbon film, etc.) and deformation (polymer film, etc.), the downstream system is first excluded. air. After the downstream vacuum degree increases, close v...

specific Embodiment approach 2

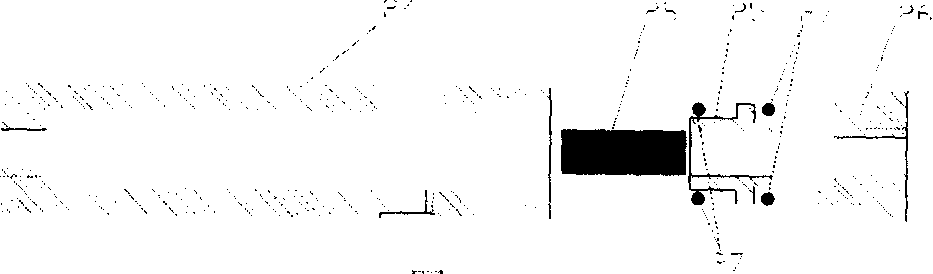

[0023] exist image 3 In the process, the two ends of the tubular membrane 28 are sealed with glue, and one end is fixed on the support 25 with glue, and O-shaped sealing gaskets 27 are respectively placed on the left and right sides of the support, and the lower cover 26 of the membrane tank is screwed into the upper cover 24 of the membrane tank and fixed.

[0024] exist figure 1 in, will image 3 The membrane pool in is connected to the position of the gas path 11 with the thermostat box, after controlling the temperature of the thermostat box 16. Close the intake valve 1, three-way valves 7 and 15, open the valve 8, and turn the valve 15 to vacuumize. In order to prevent the membrane from breaking and deforming, first remove the air in the downstream system. After the downstream pressure is about to come down, close valves 2 and 13, open valve 5 and turn valve 7 to vacuumize, vacuumize the upstream and downstream of the entire gas circuit, and use the vacuum gauge 4 to ...

Embodiment 1

[0028] The thickness is 20mm with epoxy glue, and the effective penetration area is 4.15cm 2 The circular polyimide film is fixed in the membrane cell, adopts specific embodiment 1, has obtained this organic film to hydrogen (H 2 ): 2.2 Barrer (1 Barrer = 10 -10 cm 3 (STP) cm cm -2 √ -1 mHg -1 ), carbon dioxide (CO 2 ): 1.1Barrer, oxygen (O 2 ): 0.18Barrer, nitrogen (N 2 ): 0.034Barrer; selectivity: H 2 / N 2 = 64.7, CO 2 / N 2 =32.4,O 2 / N 2 = 5.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com