Binding type thermal-insulation composite wall with support

A thermal insulation composite and bundled technology, applied in the direction of walls, building components, covering/lining, etc., can solve the problems of adding thermal bridges, complicated treatment of steel support thermal bridges, troublesome connection of steel supports and vertical steel bars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

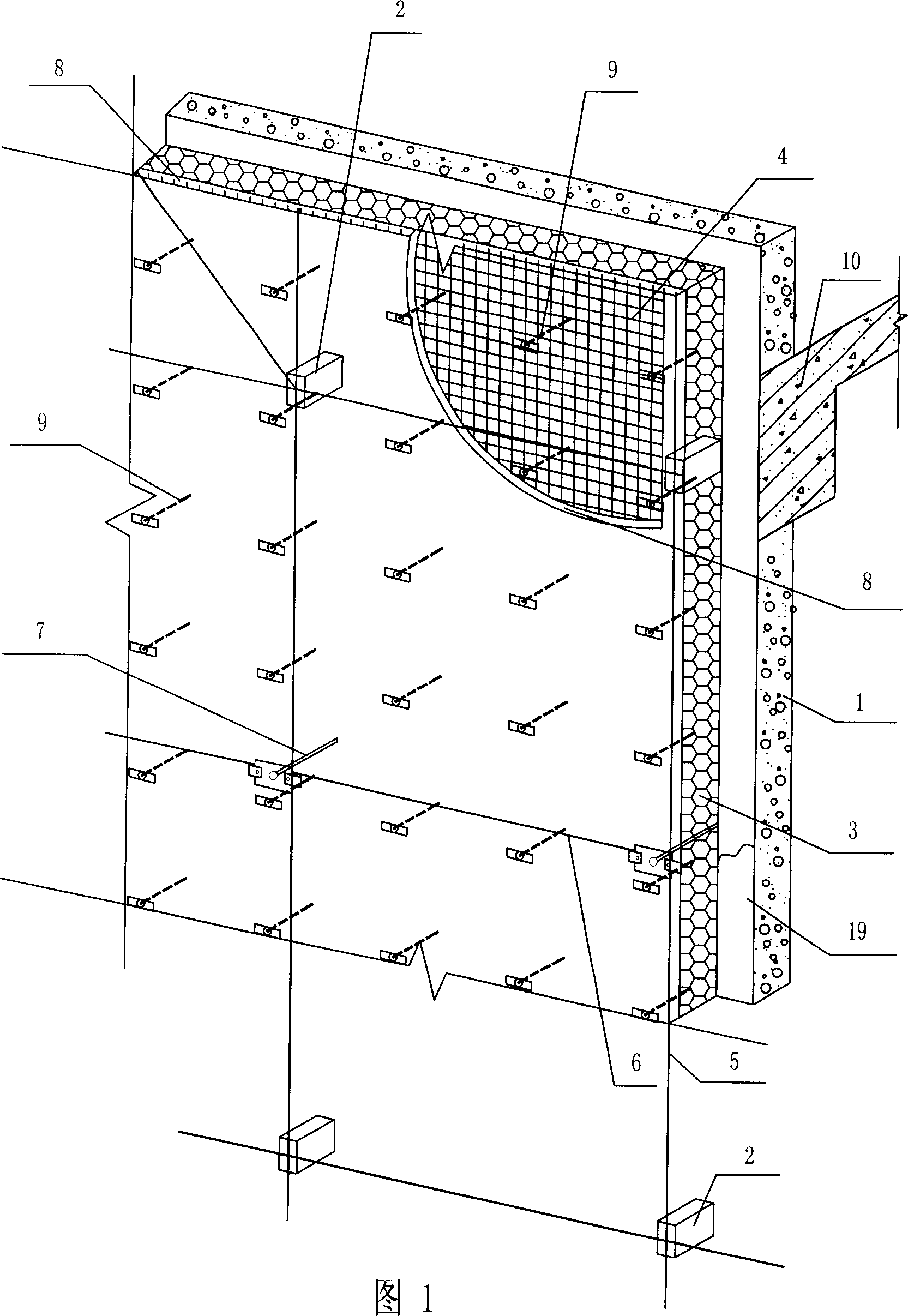

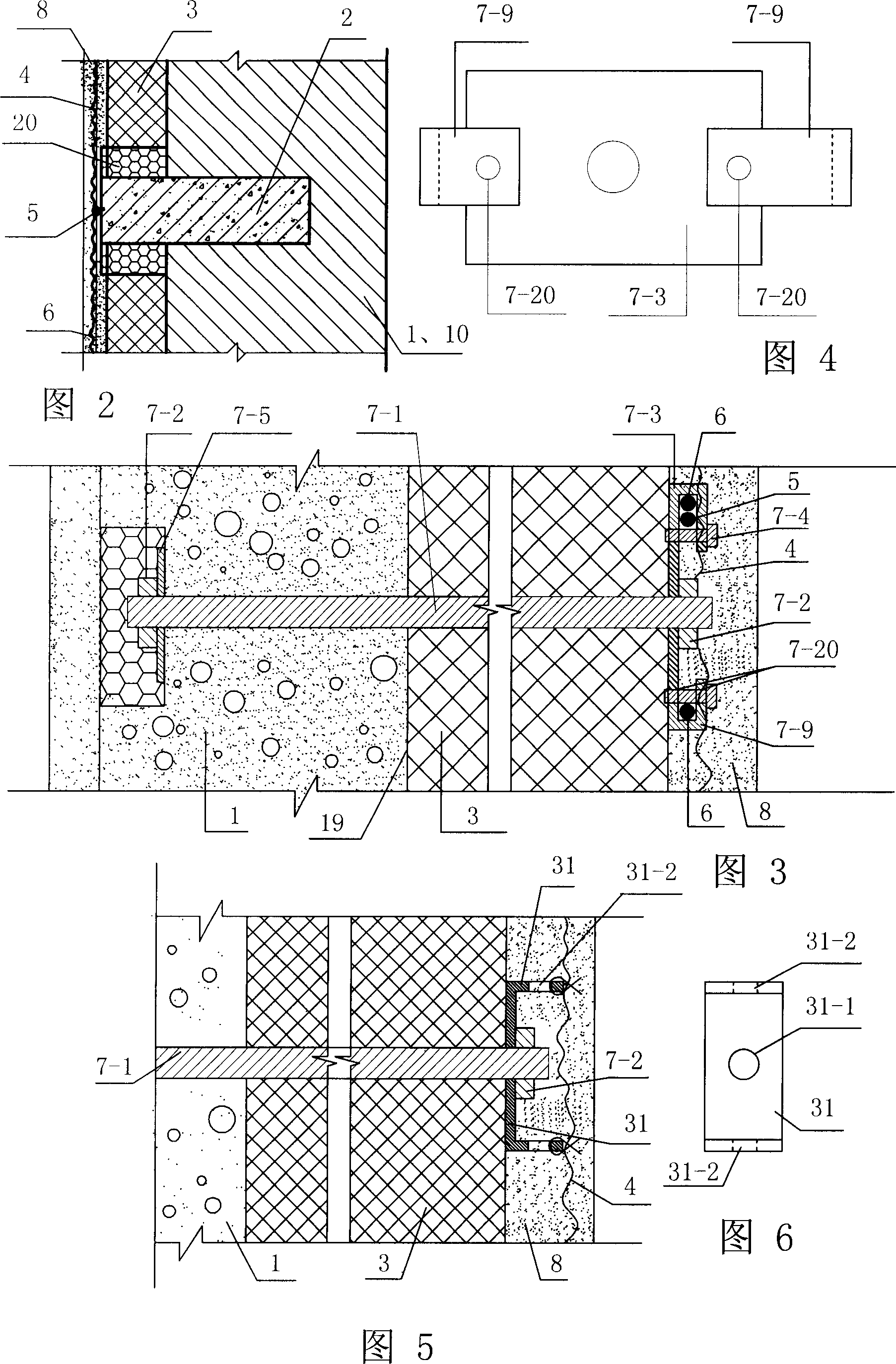

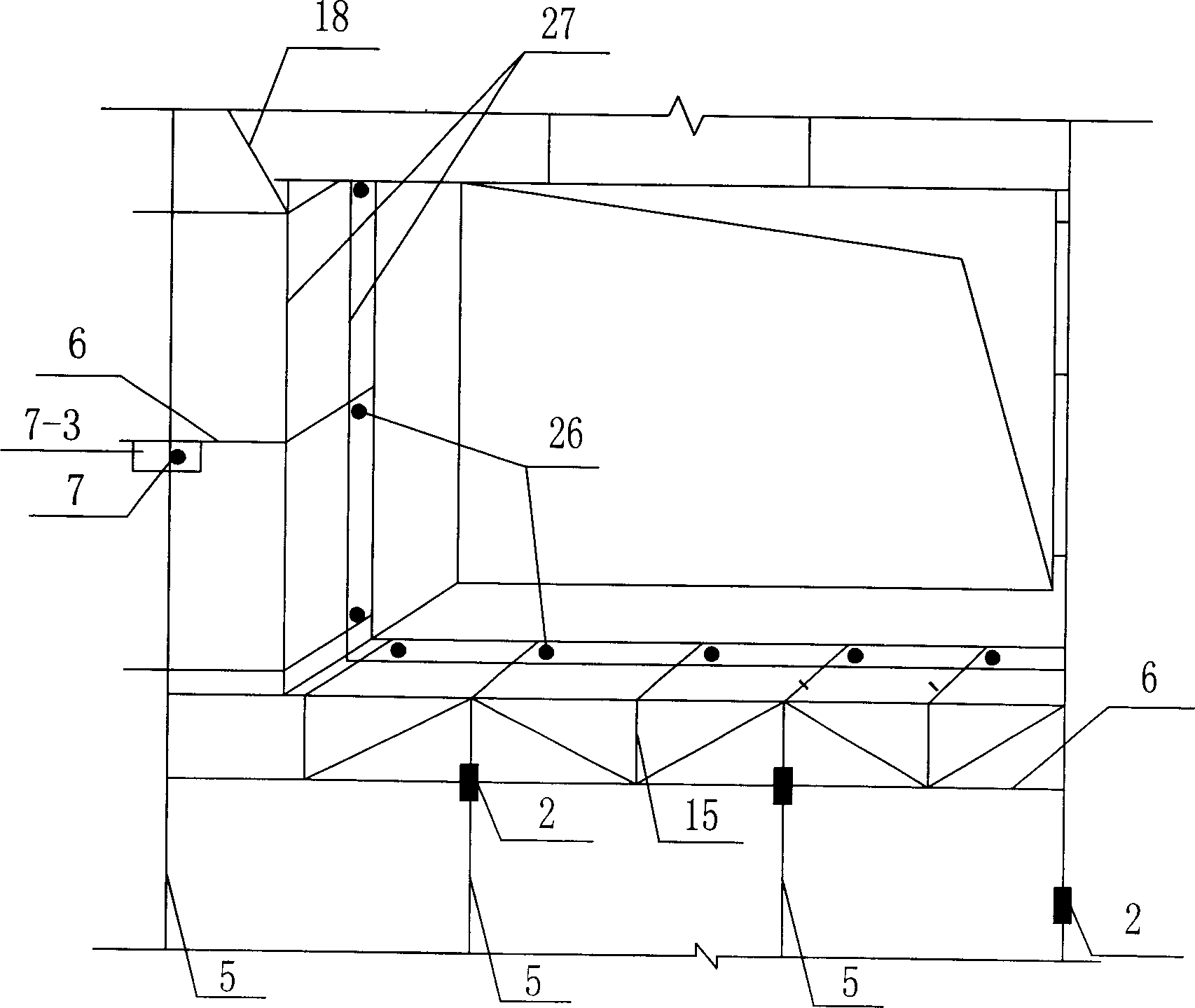

[0005] Specific embodiment one: (see Fig. 1, Fig. 2, Figure 9 , Fig. 10) the present embodiment consists of base wall body 1, concrete cantilever beam support member 2, insulation layer 3, metal mesh 4, vertical steel bar 5, internal and external pull joints 7, outer protective layer 8, plastic expansion nail 9 and Concrete components 10 of the main structure of the building consist of concrete ring beams, concrete girders, concrete columns, concrete walls, concrete lintels, concrete foundations, concrete balcony slabs, and upper and lower floors of multi-layer masonry structures. Concrete pilasters or concrete window sills on the window side connected to the surface concrete, and the inner end of the concrete cantilever beam support 2 is fixed on the inside or outside of the concrete member 10 of the main building structure and fixed with steel pieces, or fixed on the load-bearing masonry In the base wall 1, the inner end of the inner and outer pull connectors 7 is fixed in ...

specific Embodiment approach 2

[0007]Specific embodiment two (referring to Fig. 11, Fig. 12) the plastic expansion nail 9 of this embodiment is made up of plastic rod cover 9-1, plastic rod core 9-2 and the 3rd steel spacer 30, and the 3rd steel spacer 30 is set On the outer end 9-3 of the plastic rod core 9-2, the plastic rod core 9-2 passes through the hole 30-1 of the third steel gasket 30 and is driven into the plastic rod cover 9-1, and the insulation layer 3 is used The plastic expansion nail 9 is fixed, and is fixed with the metal mesh 4 with the hole 30-2 on the third steel spacer 30, and the third steel spacer 30 can also be replaced by the second steel spacer 31, and the second steel spacer 31 is located in the plastic Between the outer end 9-3 of the rod core 9-2 and the insulation layer 3, the metal mesh 4 is connected with the plastic expansion nail 9 through the hole 31-2 on the third steel gasket 31. But the third steel gasket 30 can reduce the vibration when the metal mesh 4 is plastered tha...

specific Embodiment approach 3

[0008] Specific embodiment three (referring to Fig. 1~Fig. 3, Figure 7 ~ Fig. 10): The difference between this embodiment and the specific embodiment one is that a horizontal transverse steel bar 6 is added in the outer protective layer 8, and the two ends of the horizontal transverse steel bar 6 are welded to the embedded steel plate at the outer end of the concrete cantilever beam support 2 Or be fixed on the outer end of the inner and outer pull connector 7. The setting of horizontal and horizontal steel bars can increase the binding and fixing points of the metal mesh. The horizontal horizontal steel bars and the vertical steel bars together constitute the four-sided constraints of the outer protective layer, which is more conducive to increasing the rigidity of the outer protective layer and limiting the deformation of the outer protective layer. The distance between cantilever beam supports is convenient for construction and reduces the thermal bridge of concrete cantile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com