Pressure containing heat transfer tube and method of making thereof

A heat transfer tube, axis direction technology, applied in the direction of laminated components, heat exchange equipment, heat exchanger types, etc., can solve the problems of brazing material brazing environment, increase cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

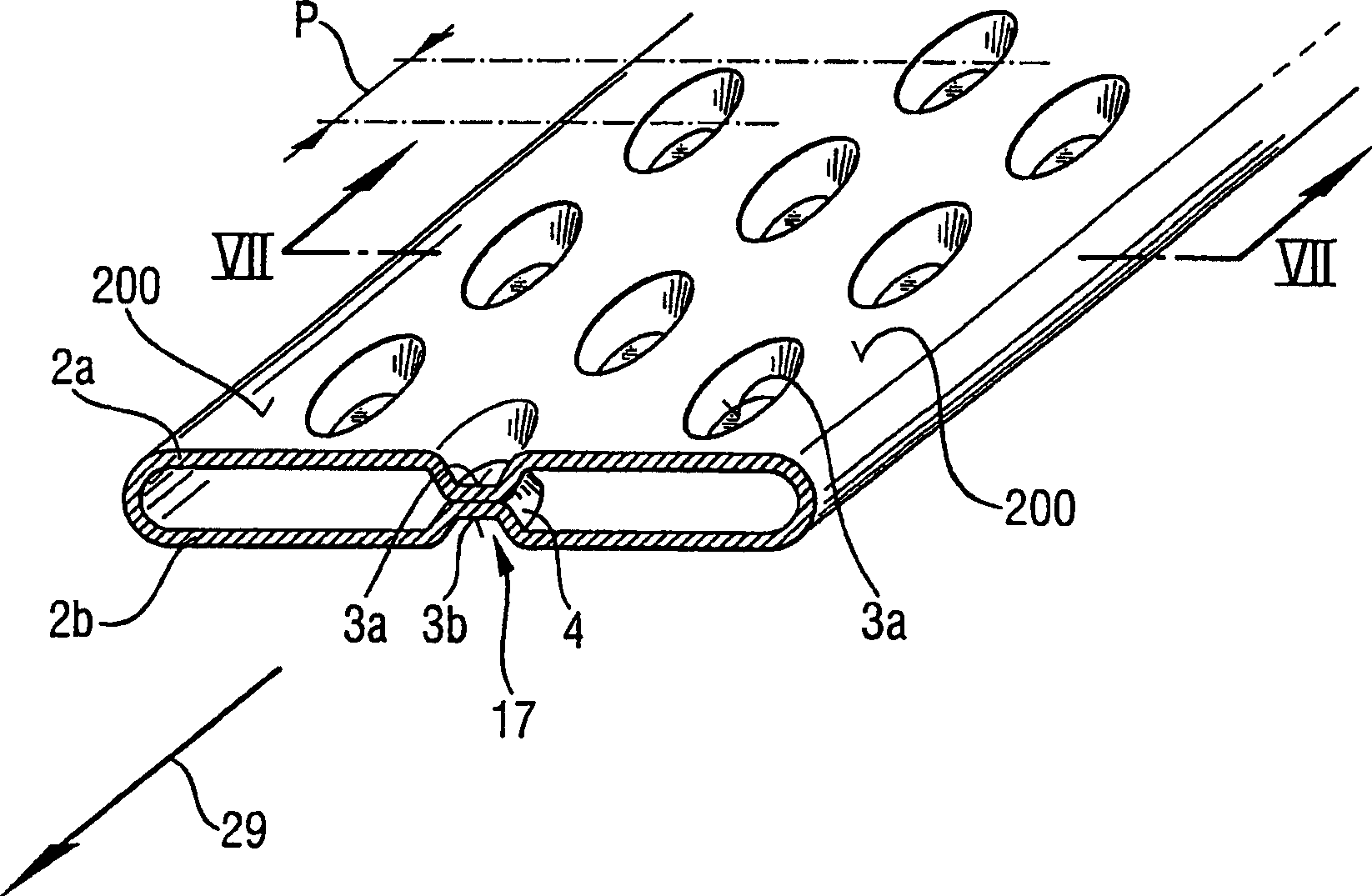

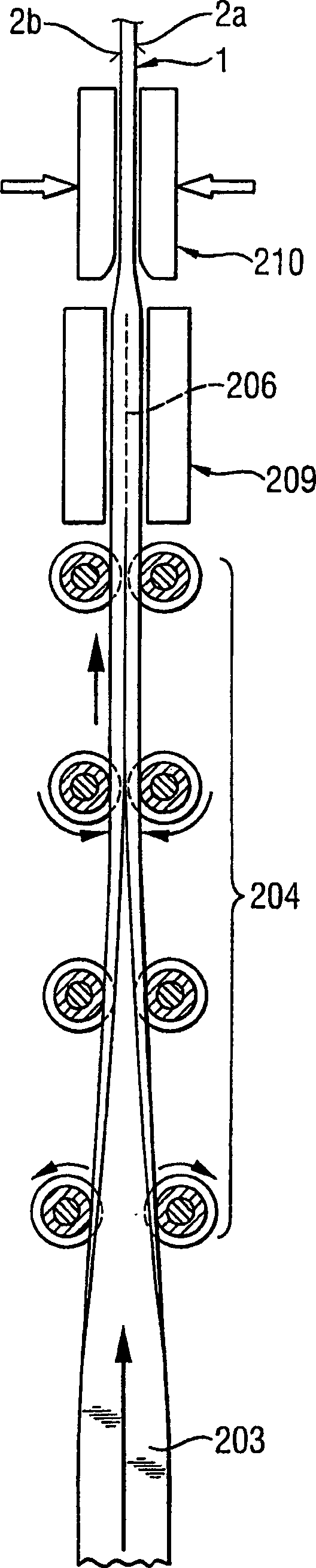

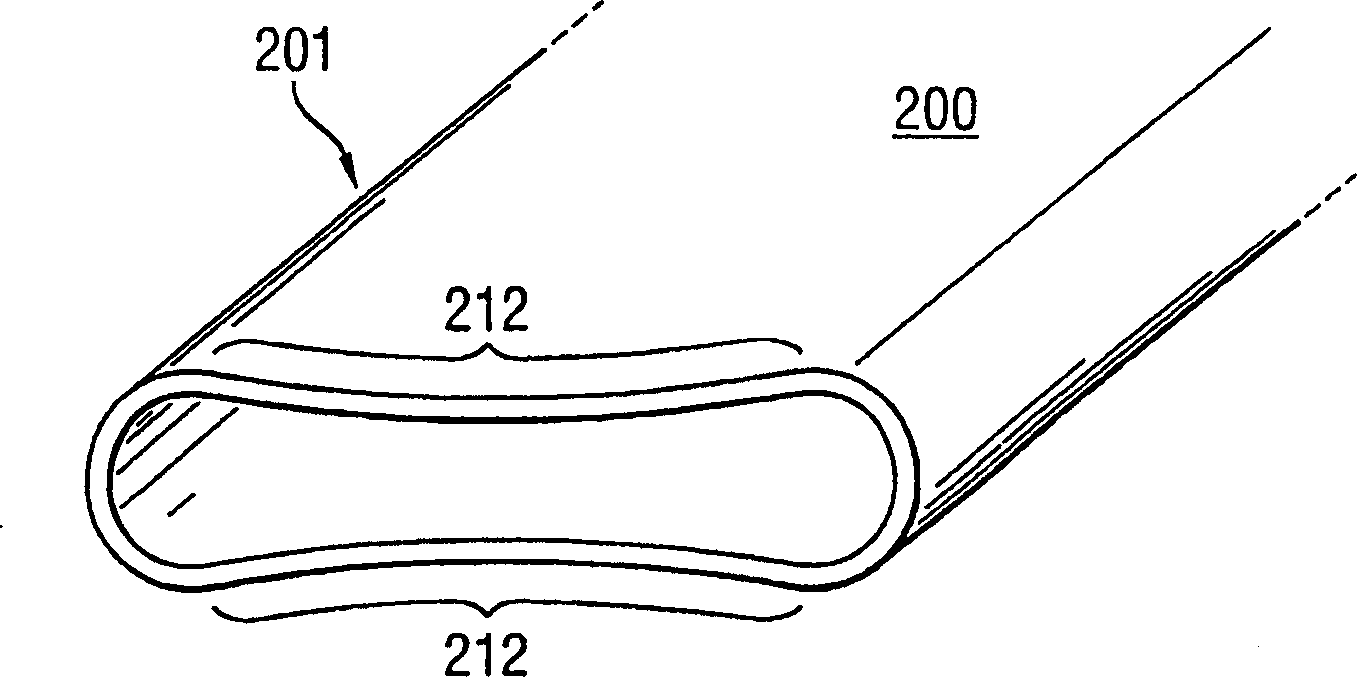

[0023] exist figure 1 In this case, the tube 1 has a main outer surface 200 formed on the outer side of the opposing walls 2a and 2b. Walls 2a and 2b are connected by a curved wall. The walls 2a and 2b also have inner surfaces. Tube 1 may consist of copper or other suitable material. The tube 1 can be formed by several methods apparent to those skilled in the art. For example figure 2 As shown in , the tube 1 can be formed by taking a flat stock 203, rolling its edges gradually with rollers 204 to form a tube, and then welding a seam 206 to join the edges. The seams may be welded by means 209 in a continuous process. Apparatus for continuous welding of pipes are generally known and will therefore not be described in detail here. If the tube 1 is first formed into a circular profile, the tube is then flattened by a press 210 to form a flat tube with opposing walls 2a and 2b. In other words, the tube can be formed into a flat tube structure and welded to form. Likewise,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com