Self exciting oscillation pipeline type flocculating device

A technology of self-excited oscillation and flocculation, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems such as few, no introduction of pipeline flocculator, etc., to enhance the degree of turbulence, improve bridging and adsorption The effect of reducing the cost of civil construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

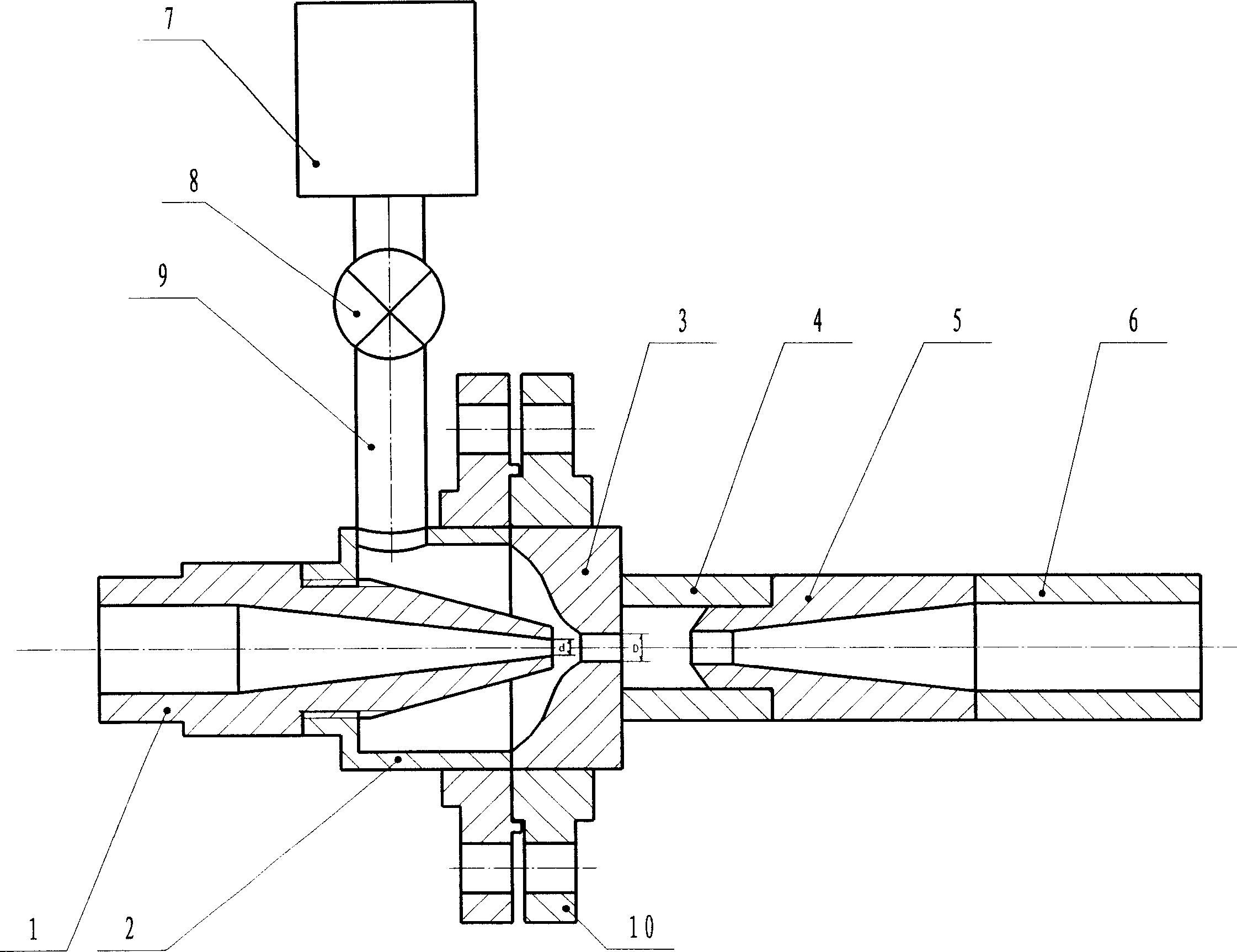

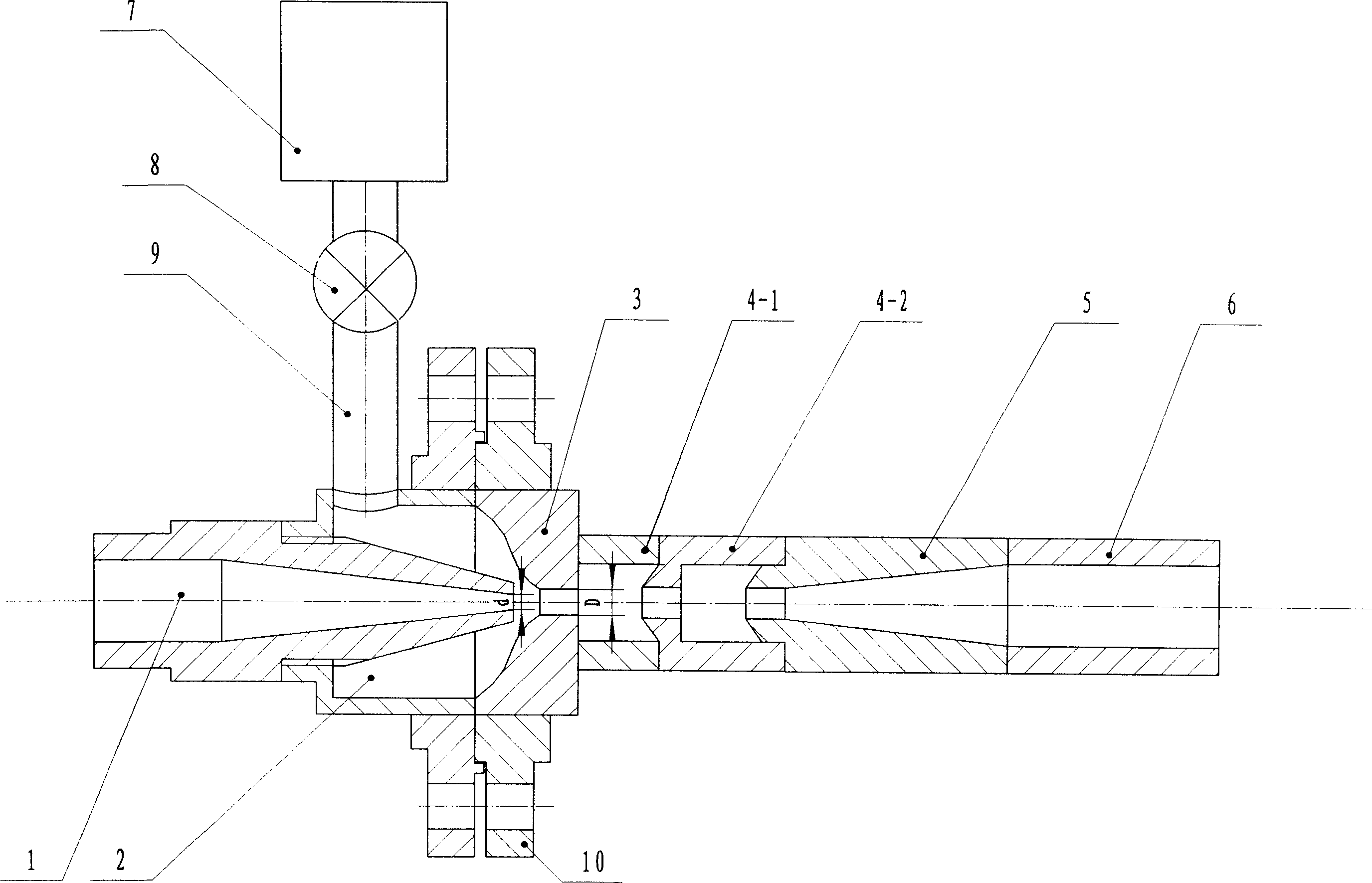

[0023] In the attached drawing, the water nozzle, the mixing chamber, the upper nozzle body, the self-excited oscillation chamber and the lower nozzle body are installed on the same center line in sequence, and the dosing tank, the flow regulating valve and the flocculant delivery pipe are sealed and fixed in sequence. , the outlet hole end of the flocculant conveying pipe is fixedly communicated with the mixing chamber. The sealing and fixing can be connected by thread, welding or flange.

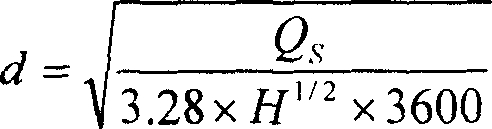

[0024] Water nozzle diameter d: d = Q S 3.28 × H 1 / 2 × 3600

[0025] In the formula, Q s is the pump flow rate, m 3 / h; H is the head of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com