Nonaqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in secondary batteries, battery components, circuits, etc., can solve the problems of safety and security against internal short circuit, and achieve short circuit resistance. Prevents the deterioration of discharge characteristics and has an excellent disconnection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

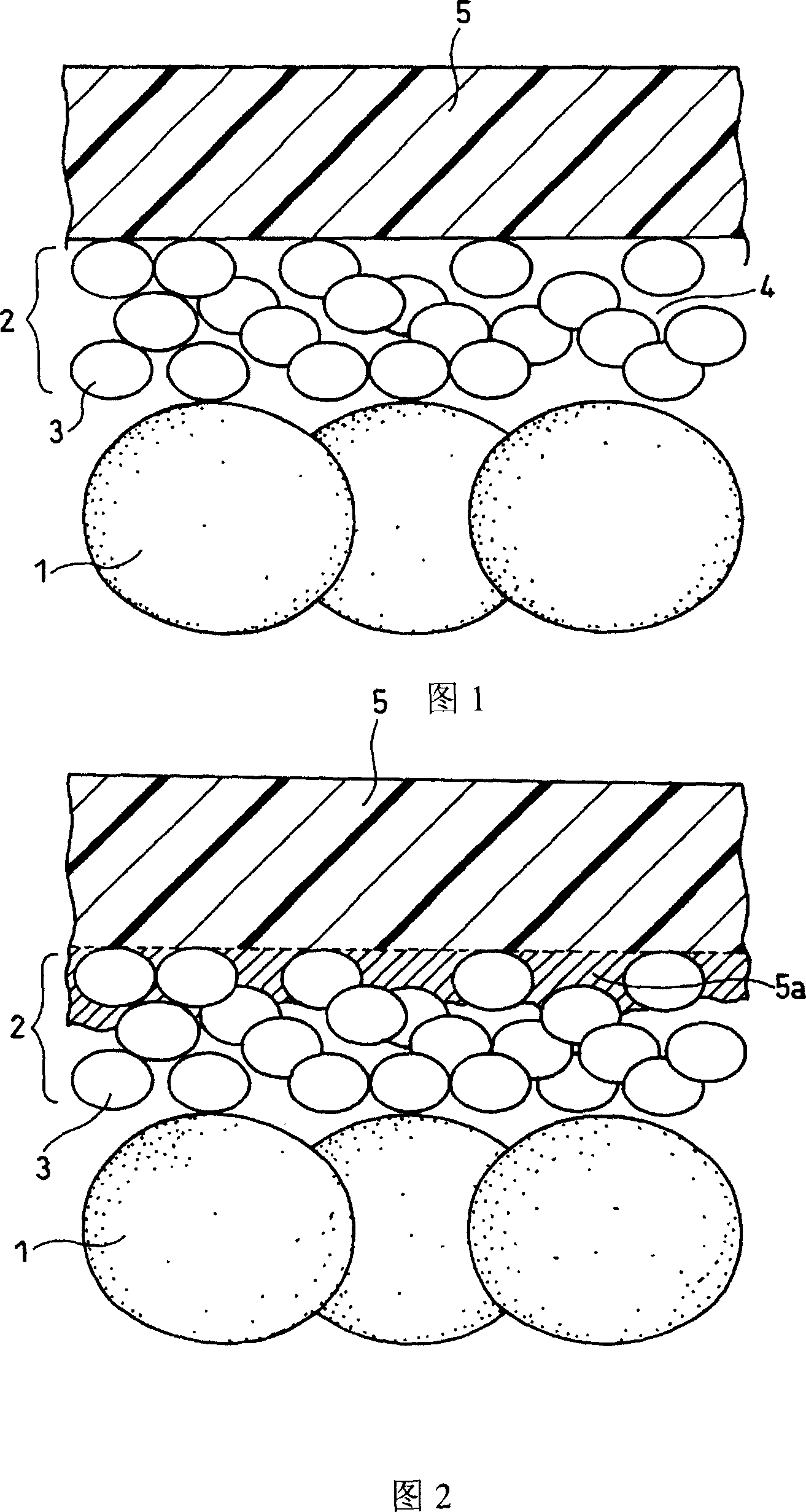

Method used

Image

Examples

Embodiment 1

[0083] (i) Manufacture of positive electrode

[0084] Mix 3kg of lithium cobalt oxide (positive electrode active material) and 1kg of #1320 (trade name, produced by Kureha Chemical Industry Co., Ltd., a NMP solution containing 12wt% PVDF (positive electrode binder) while stirring using a double-arm kneader ), 90g of acetylene black (conductive material) and an appropriate amount of NMP to prepare the positive electrode material mixed slurry. This slurry was applied to both surfaces of an aluminum foil (positive electrode current collector) having a thickness of 15 μm (excluding the positive electrode lead connecting member). The dry coating is rolled to form a positive electrode material mixture layer. Thus, a positive electrode ring was obtained. The electrode plate is composed of aluminum foil and a layer of positive electrode material mixture with a thickness of 160 μm. Thereafter, the positive electrode hoop was cut into a size of 60 mm in width and 500 mm in length. A...

Embodiment 2

[0108] (i) Manufacture of positive electrode

[0109] Mix 3kg lithium cobalt oxide (positive electrode active material) and 1kg#1320 (trade name, produced by Kureha Chemical Industry Co., Ltd., a kind of NMP solution containing 12wt% PVDF (positive electrode binder)) while stirring while using a double-arm kneader , 90g of acetylene black (conductive material) and an appropriate amount of NMP to prepare the positive electrode material mixed slurry. This slurry was applied to both surfaces of an aluminum foil (positive electrode current collector) having a thickness of 15 μm (excluding the positive electrode lead connecting member). The dry coating is rolled to form a positive electrode material mixture layer. During the formation of the positive electrode material mixture layer, the thickness of the electrode plate composed of the aluminum foil and the positive electrode material mixture layer was controlled at 160 μm. Then, the electrode plate was cut to a width that could ...

Embodiment 3

[0128] Batteries were manufactured in the same manner as in Example 2, except that in the preparation of the porous film coating, the time of primary mixing was changed to 10, 20, 45 and 60 minutes. The porosity P of the porous insulating film was 0.60, 0.60, 0.58 and 0.55, respectively. Therefore, the R-P values are 0, 0, 0.02 and 0.05.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com