Resource separation of waste lithium ion battery

A lithium-ion battery and separation method technology, which is applied in the field of resource separation of waste lithium-ion batteries, can solve problems such as inadequacy, and achieve the effect of retaining usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

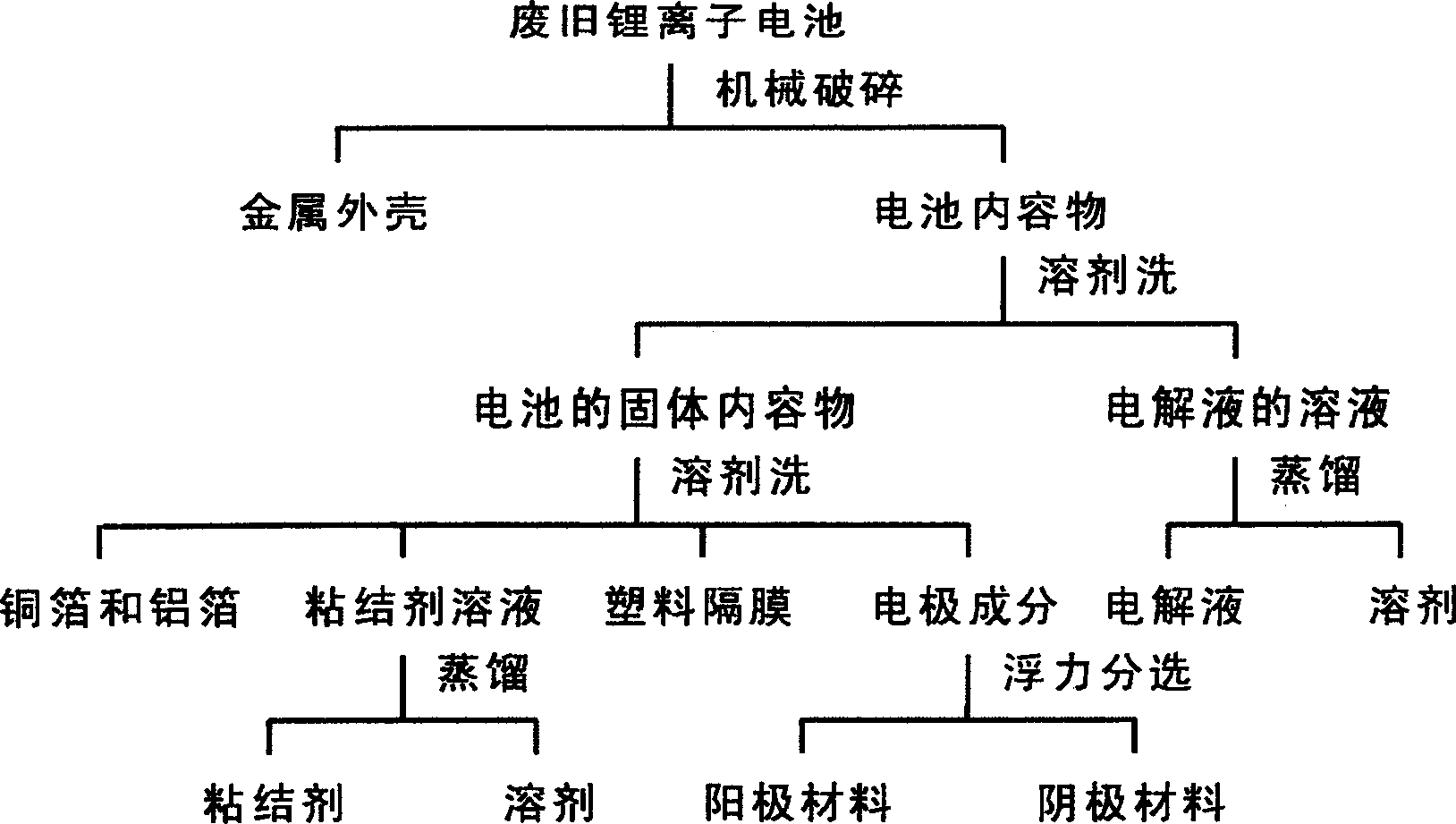

[0015] 1. Mechanical crushing of batteries:

[0016] To make reprocessing easier, the battery must be crushed in a gentle manner. In the laboratory, a hacksaw can be used to saw the casing; in industry, a machine can be used to peel off the battery's plastic and metal casing, thereby separating the battery's metal casing from the battery's contents.

[0017] Existing lithium-ion batteries generally use a method in which cathode and anode active materials are coated on copper foil and aluminum foil respectively, and a plastic separator is used to separate the electrode materials from direct contact. In order to make subsequent processing more convenient, the electrode should be cut into 1cm to 5cm square pieces.

[0018] 2. Separation of electrolyte from other solid contents

[0019] Use polar organic solvents, such as dichloromethane, chloroform, acetone, ethanol, etc., to wash out the electrolyte contained in the battery content, and separate the electrolyte solution from o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com