Overball inspection and external inspecting system for loading-unloading system of ball-bed piled fuel component

A fuel element, loading and unloading system technology, applied in reactors, nuclear reactor monitoring, nuclear power generation, etc., can solve problems such as difficult installation, long construction time, radiation pollution, etc., to ensure integrity and high pressure airtightness, solve convenience and The effect of using reliability and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

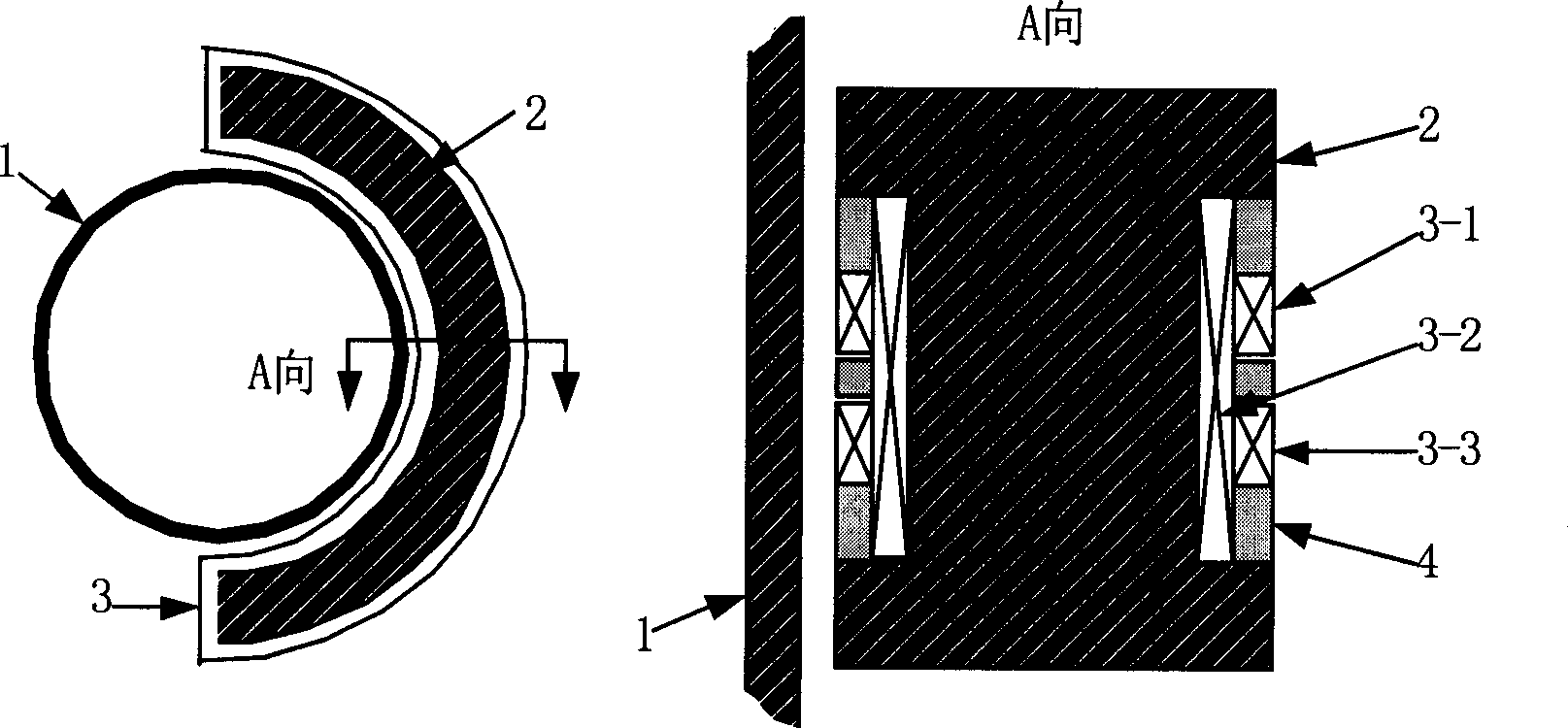

[0058] The principle of the present invention is: the coil of alternating current can generate alternating electromagnetic field near it, and eddy current can be generated in the conductor (graphite ball) near the coil, and the eddy current produced can affect the space electromagnetic field in turn, thereby It affects the amplitude and phase of the coil voltage. By detecting the change of the amplitude and phase of the coil voltage, it can be judged whether there is a conductive graphite ball passing through.

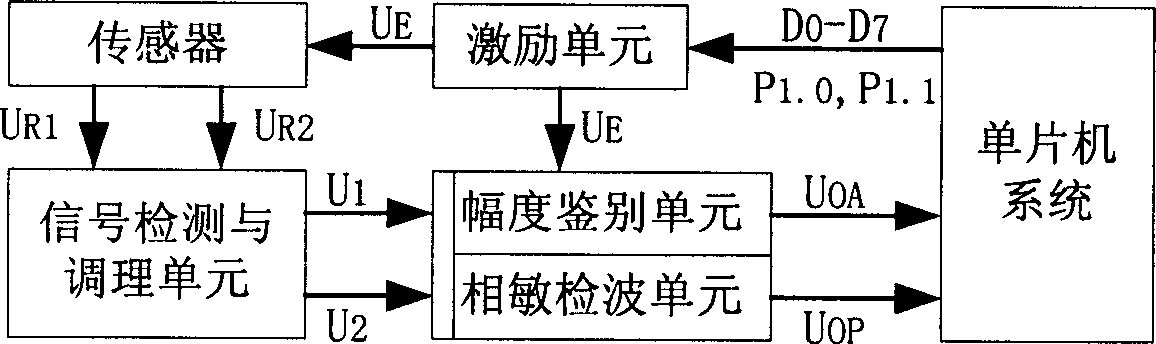

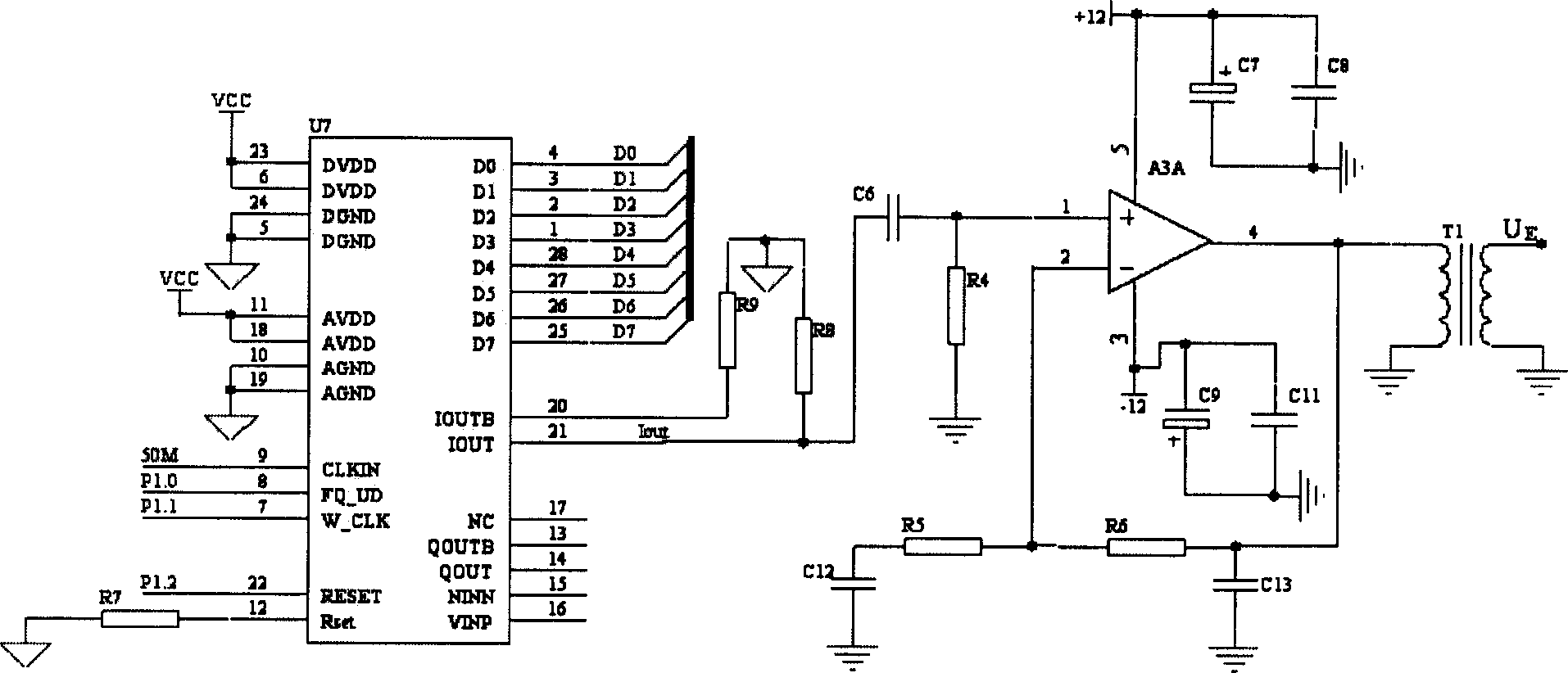

[0059] The working principle of the ball passing detection system of the present invention is as follows: figure 1 shown. The single-chip microcomputer controls the excitation unit to generate a 1K-8K stable amplitude sinusoidal AC excitation signal U E , the excitation coil acting on the sensor generates a stable alternating ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com