Reciprocating petroleum beam-pumping unit with hydraulic transmission

A technology for hydraulic transmission and oil extraction, which is applied in the development of fluids, transmission devices, fluid transmission devices, etc., can solve the problems of low failure, insufficient long-life working performance requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

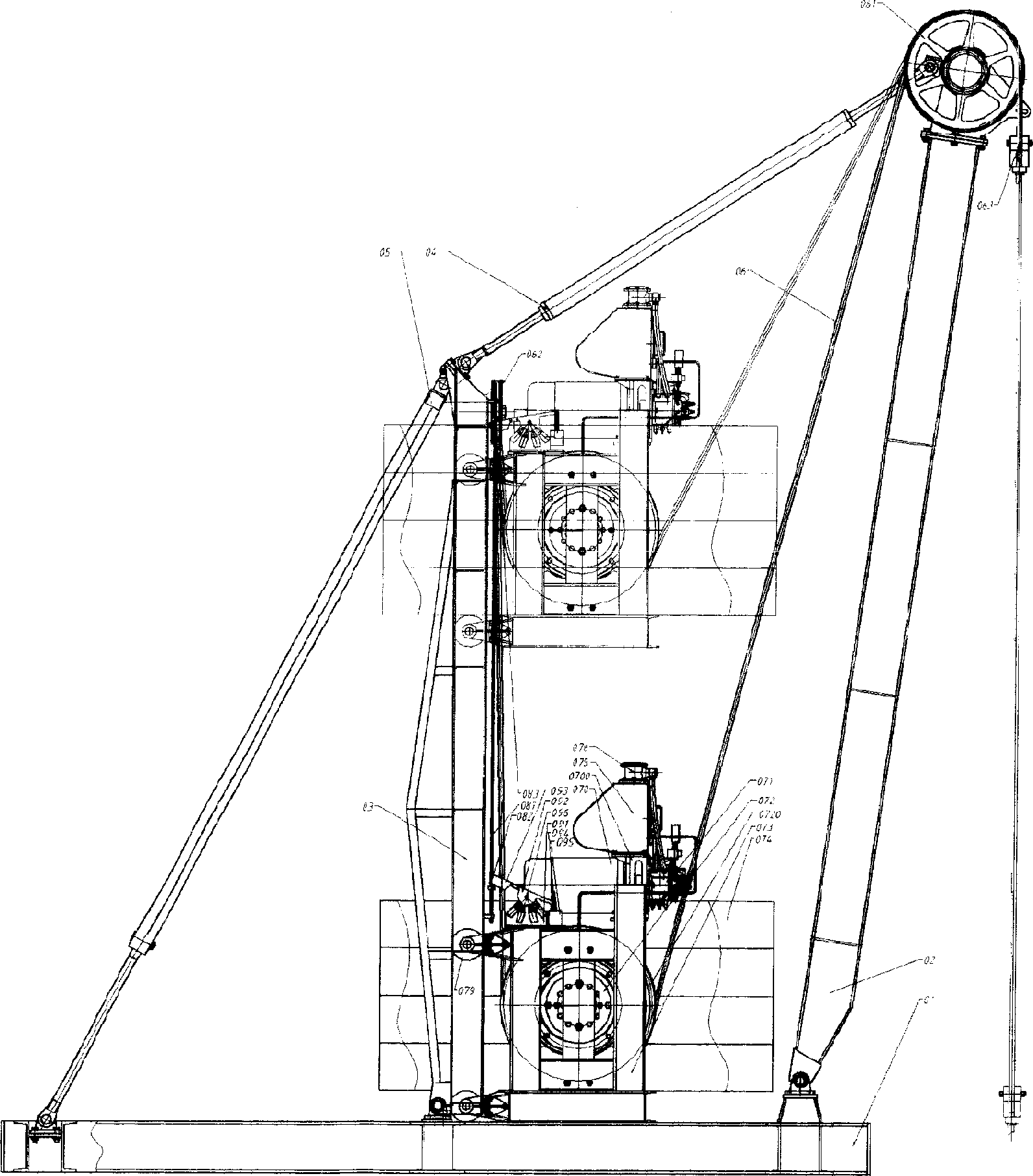

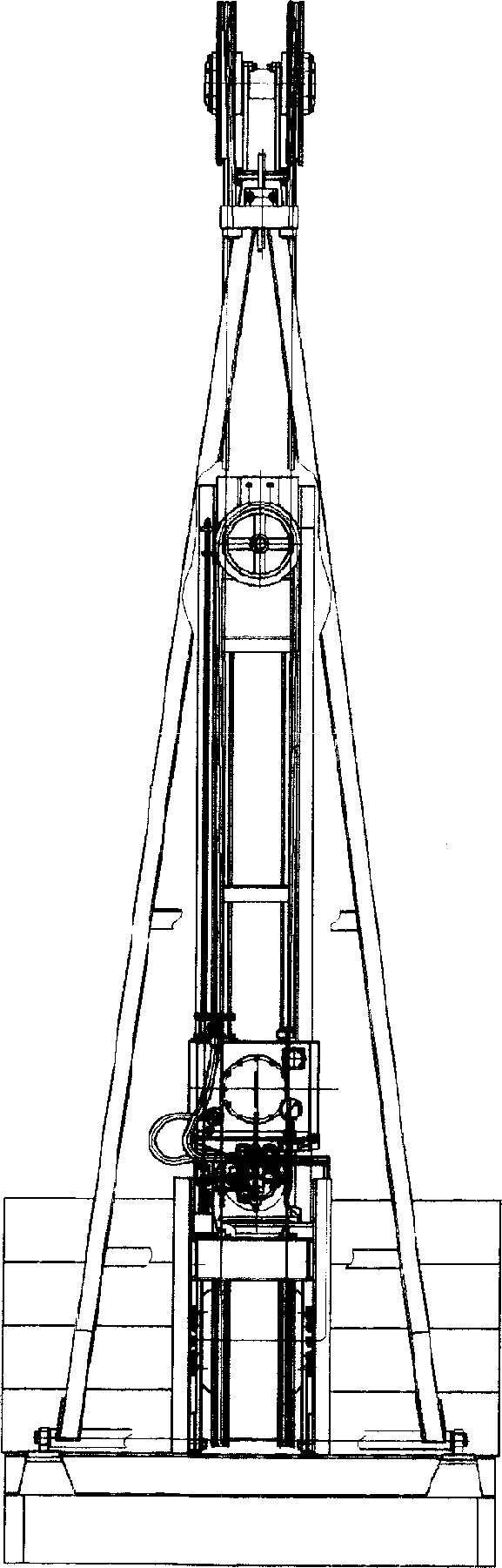

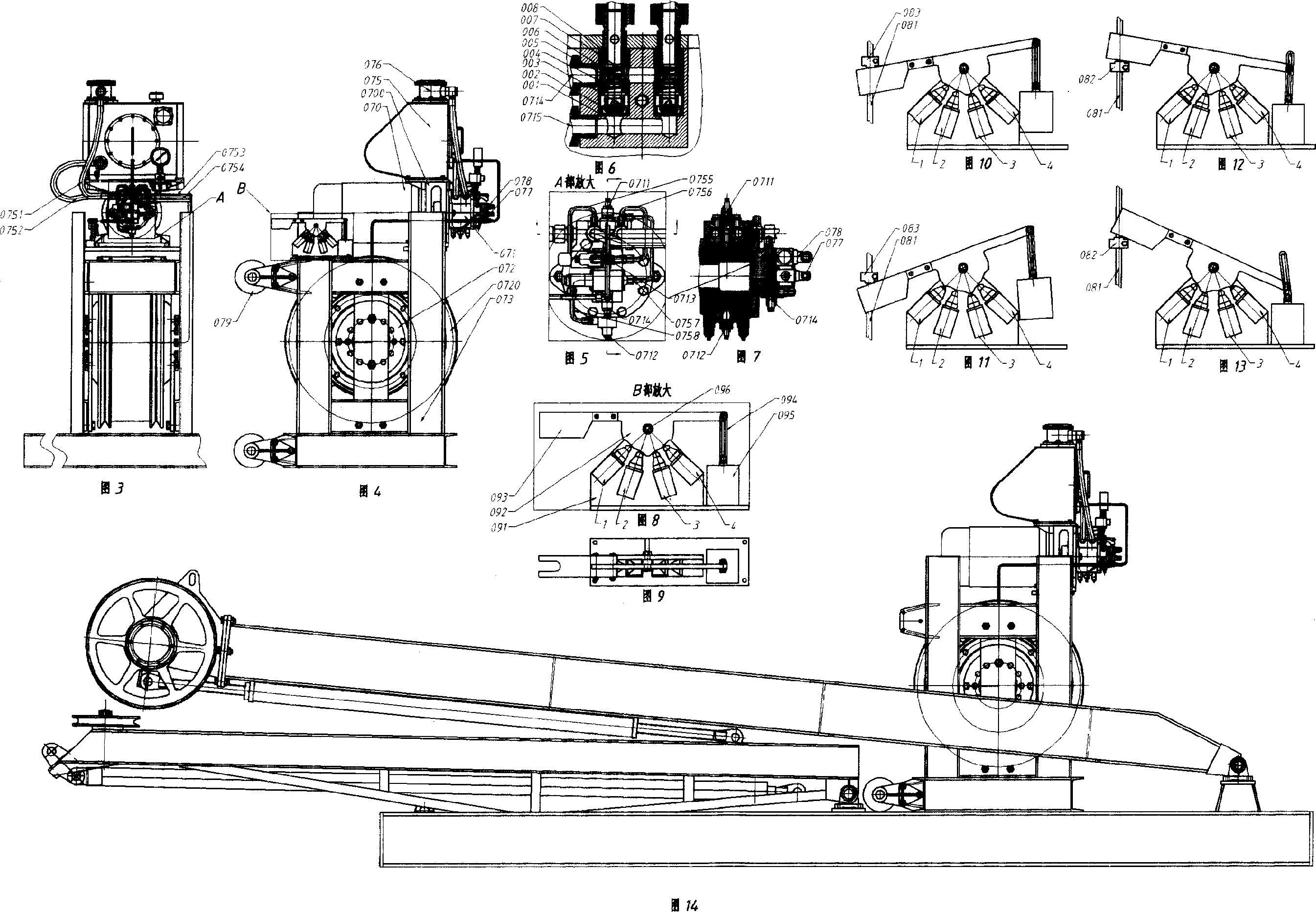

[0016] Here, a typical model of a hydraulically driven oil extraction pumping unit is used as an example to describe the specific implementation of the present invention.

[0017] The overall structure of this embodiment is as figure 1 and figure 2 As shown: the base 01, the front bracket 02, the rear bracket 03, the upper tie rod 04, and the diagonal tie rod 05 are connected by hinges to form a light and stable frame structure. (Also refer to Fig. 3 to Fig. 8) The slider type variable, reversing hydraulic pump 071, motor 070, working fluid tank 075, working fluid return filter 076, control valve and pipeline accessories are connected together by the connection base 0700 It constitutes a hydraulic power source as a whole; the outer circumference of the transmission disc of the low-speed high-torque hydraulic motor 072 driven by the slider type disc is directly assembled with the transmission sheave 0720 with two V-shaped transmission grooves on the outer peripheral surface t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com