Double-pipe reactor

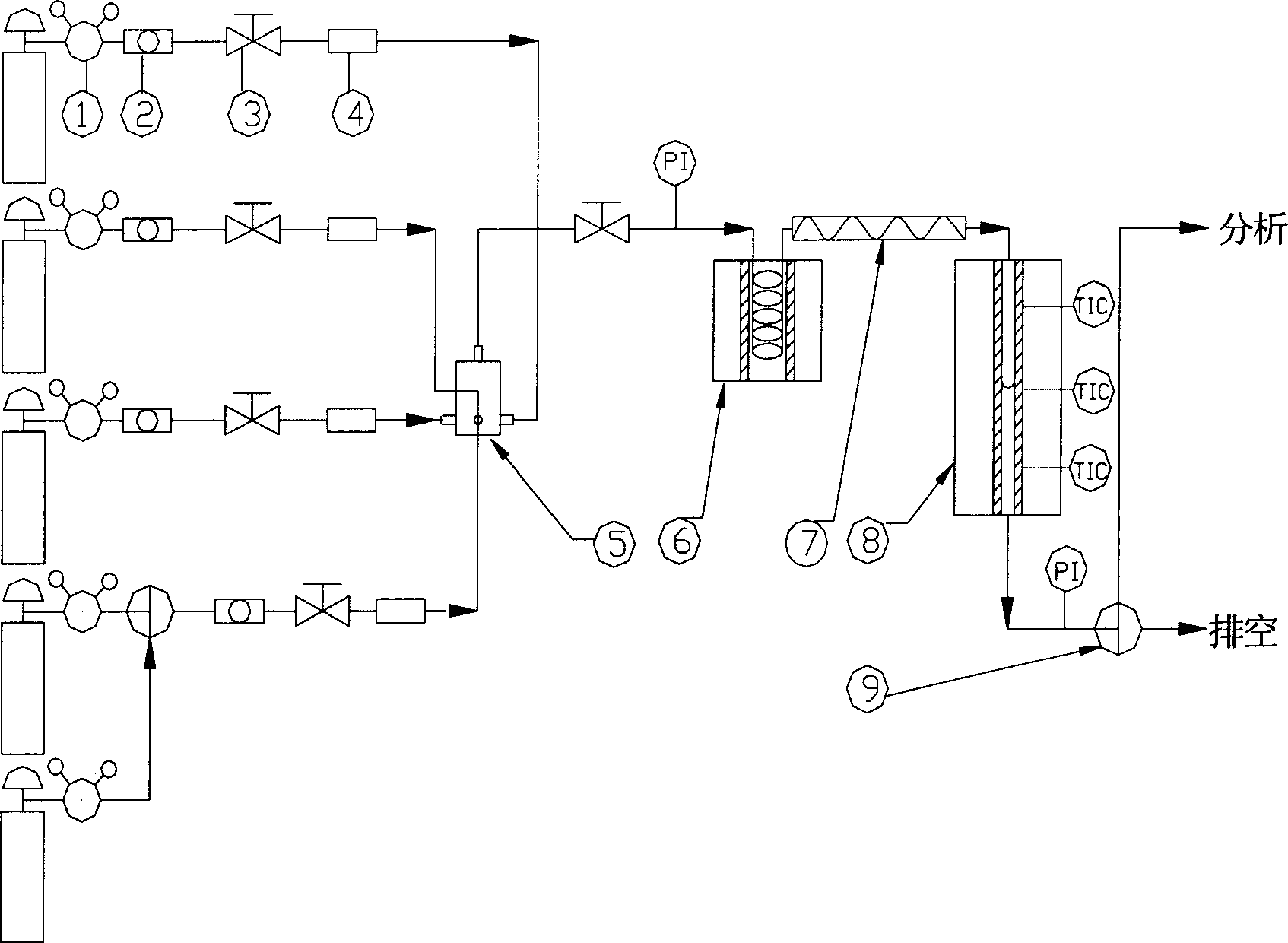

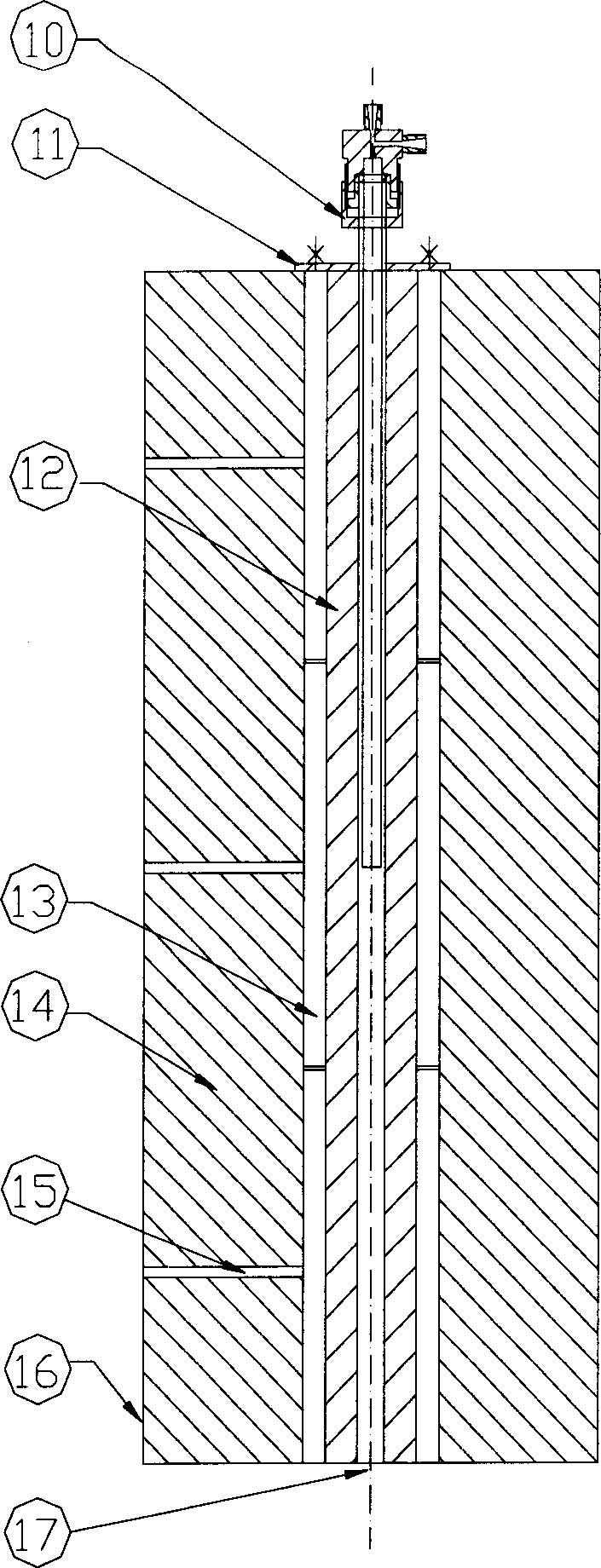

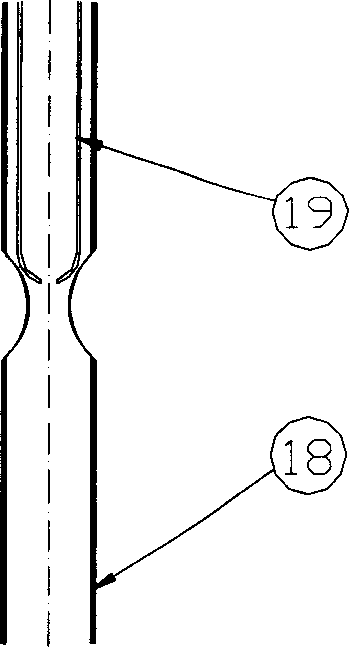

A sleeve reactor and reactor technology, applied to laboratory appliances, chemical instruments and methods, and laboratory containers, can solve the problems of large temperature gradient, time-consuming, and high space requirements in fixed beds, and achieve Reduce the time of catalyst loading, facilitate manual disassembly, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] 1. Temperature distribution curve in the reactor

[0033] see Figure 5 , it can be seen that in the range of <800°C, with the continuous increase of the set temperature, the axial temperature distribution of the reactor presents a trend of two low sections and a high middle section, but even at 800°C, the length of the constant temperature section still reaches 300mm. This fully demonstrates that the three-segment resistance wire heating can effectively ensure the uniform temperature distribution in the axial direction of the reactor, and the temperature gradient is greatly reduced compared with the single-segment resistance wire heating, so that the temperature of the loaded catalyst bed is consistent and the reliability of the experimental measurement data is improved. Sex; at the same time, the service life of the heating furnace is greatly extended.

[0034] 2. Application examples of catalytic reactor evaluation system

[0035] Co-Mo / γ-Al 2 o 3 Taking the eval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com