Fluid-drop-flowing injection device and quantitative analysing method

A technology of flow injection and droplet, which is applied in the direction of analyzing materials, measuring devices, and material analysis through optical means, and can solve problems that do not involve the process of droplet coalescence and droplet coalescence reaction, and the optimal mixing of samples and reagents It is difficult to guarantee the ratio, increase the consumption of reagents or samples, etc., and achieve the effects of reducing instrument costs, low production costs, and less sample consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

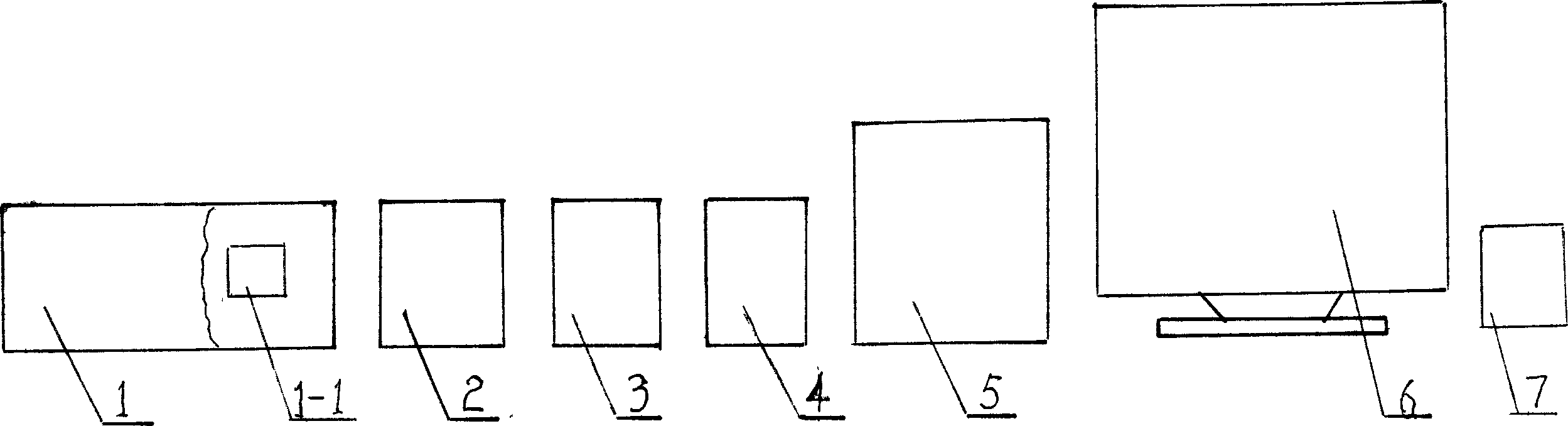

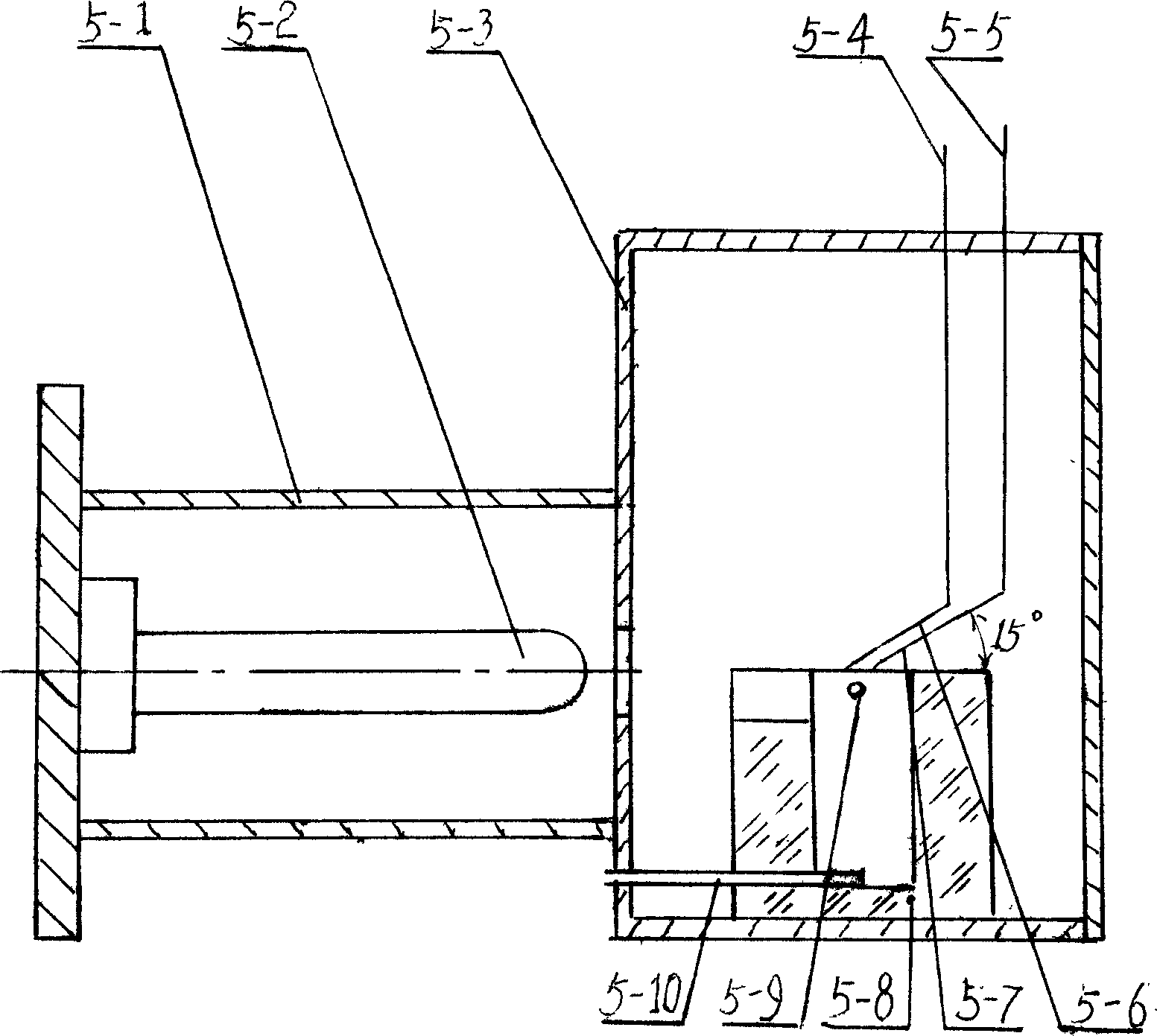

[0043] exist figure 1 Among them, the droplet flow injection device of this embodiment consists of a negative high pressure controller 1, a constant flow pump 2, a syringe pump 4, a peristaltic pump 3, a chemiluminescence instrument 5, a computer 6, a potentiostat 7, and a waste liquid pipe 5-10. Join composition.

[0044] The negative high voltage controller 1 and the potentiostat 7 are connected to the chemiluminescence instrument 5 through wires, communicate with the chemiluminescence instrument 5 through the catheter of the constant current pump 2, and communicate with the chemiluminescence instrument 5 through the catheter of the syringe pump 4, and the chemiluminescence The instrument 5 is connected with the negative high voltage controller 1 through a wire, and the negative high voltage controller 1 is equipped with an A / D converter, and the A / D converter is connected with the computer 6 through a cable. The constant current pump 2, the injection pump 4, the peristalti...

Embodiment 2

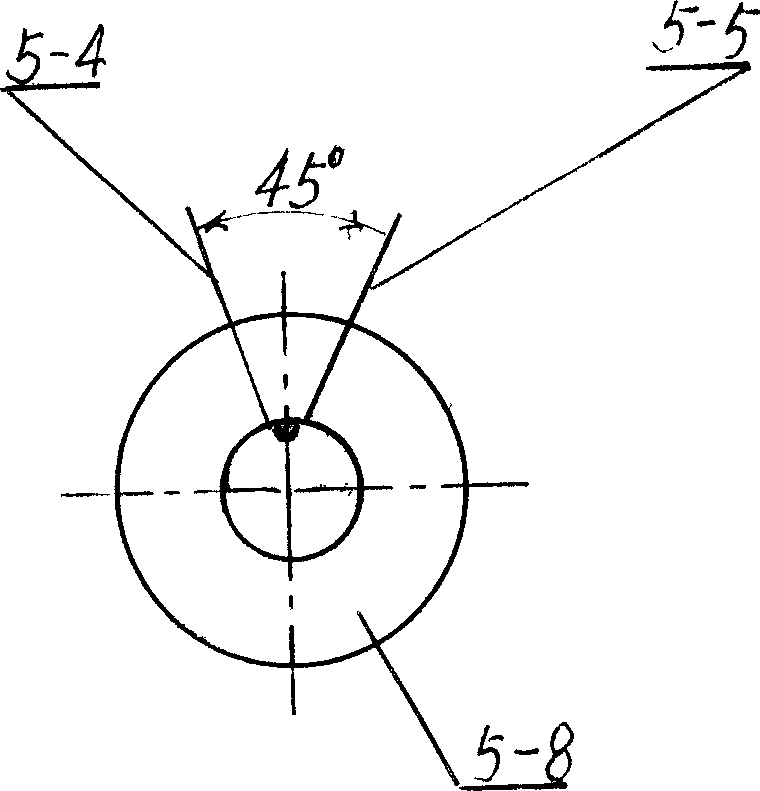

[0068] In this embodiment, the sample inlet tube 5-6 and the reagent inlet tube 5-7 are quartz capillary tubes with an inner diameter of 325 μm, and the electrodes are platinum electrodes. The distance between the nozzles is 0.5mm, the angle between the sample inlet tube 5-6 and the reagent inlet tube 5-7 is 60°, the sample inlet tube 5-6, the reagent inlet tube 5-7 and the luminescence reaction cell 5-8 The included angle of the upper surface is 10°, and the light-emitting reaction pool 5-8 is a light-emitting reaction pool 5-8 made of transparent silicon glass material. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0070] In this embodiment, the sample inlet pipe 5-6 and the reagent inlet pipe 5-7 are quartz capillary tubes with an inner diameter of 500 μm, and the electrodes are platinum electrodes. The distance between the nozzles is 2.0mm, the angle between the sample inlet tube 5-6 and the reagent inlet tube 5-7 is 45°, the sample inlet tube 5-6, the reagent inlet tube 5-7 and the luminescent reaction cell 5-8 The included angle of the upper surface is 30°, and the light-emitting reaction pool 5-8 is a light-emitting reaction pool 5-8 made of transparent silicon glass material. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com