Functionalized polyolefin long-acting trickle film and preparing method

A polyolefin and functionalization technology, which is applied in the field of functionalized polyolefin long-acting dripping film and its preparation, can solve the problems of no double bond reactive group, short dripping duration of dripping film, etc. Homopolymerization tendency, effect of inhibiting degradation or crosslinking reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

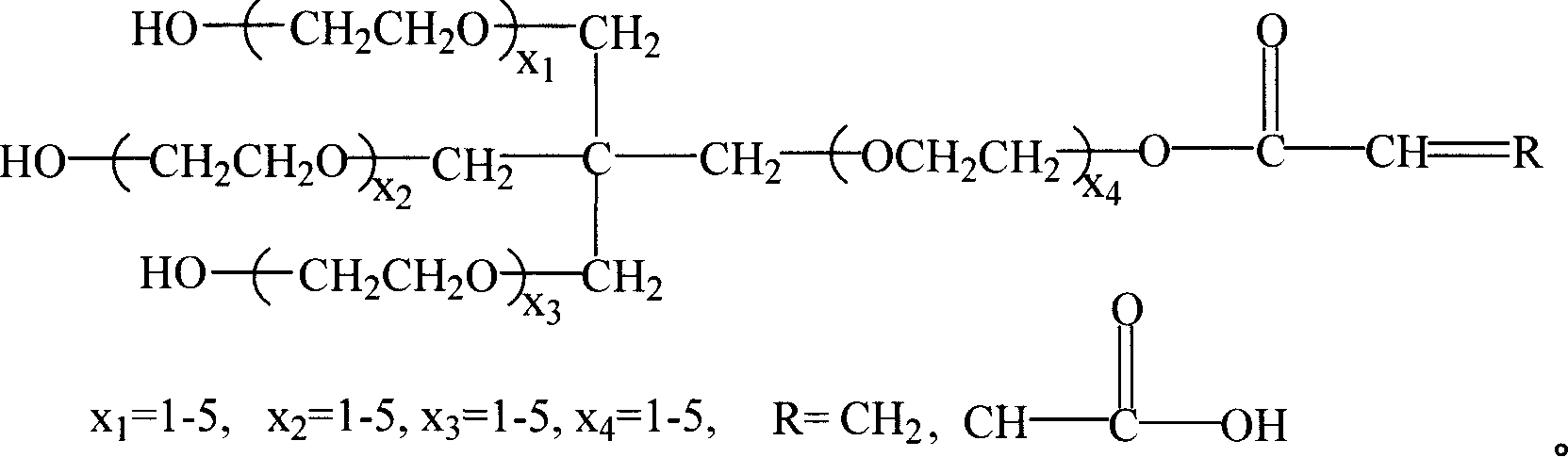

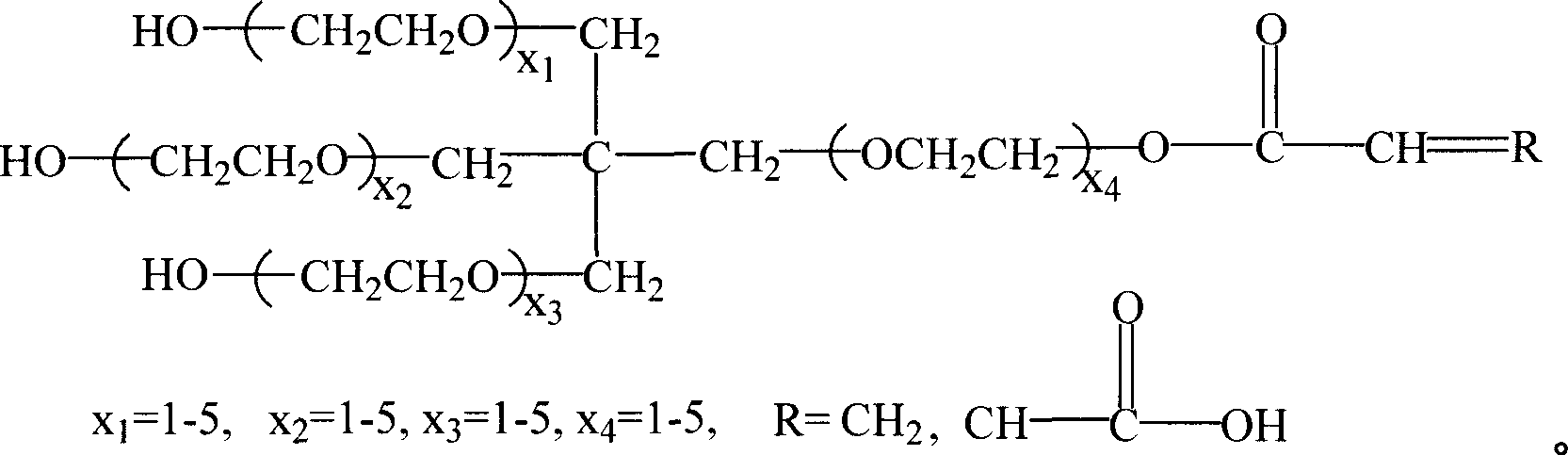

Image

Examples

Embodiment 1

[0023] 0.19mol of polyether tetraol with a molecular weight of 840, 0.11mol of xylene, and 2×10 hydroquinone -4 mol, p-toluenesulfonic acid 2×10 -4 mol is added to the reactor equipped with stirrer, thermometer, reflux condenser, liquid dropping tube, nitrogen gas inlet tube and heating device, and 0.19mol maleic anhydride is dissolved in the liquid dropping tube filled with 0.49mol acetone , feed nitrogen, heat and stir, raise the temperature of the liquid in the reactor to 50°C, turn on the switch of the liquid dripping tube, start to add the liquid dropwise, the dropping time is 30 minutes, after the addition is completed, the temperature is raised to 100°C, and the reaction is 2 hours. After finishing the reaction, lower the temperature to 65° C., reduce the pressure to -0.08 MPa, remove the solvent, and obtain the functional monomer of the reactive functionalized polyolefin long-lasting dripping film.

[0024] 100 parts (mass) of low-density polyethylene (LDPE) are pre-i...

Embodiment 2

[0028] 1.875mol of polyether tetrahydric alcohol with a molecular weight of 1016, 9.075mol of toluene with p-dodecylbenzenesulfonic acid 1.5×10 -2 mol, hydroquinone 1.5×10 -2 mol is added to the reactor equipped with stirrer, thermometer, reflux condenser, liquid dripping tube, nitrogen pouring tube and heating device, 1.875mol of acrylic acid solution is placed in the liquid dripping tube, nitrogen gas is introduced, heated and stirred , raise the temperature of the liquid in the reactor to 50°C, turn on the switch of the liquid dripping tube, and start to add the liquid dropwise for 40 minutes. °C, reduce the pressure to -0.12MPa, remove the mixed solvent, and obtain the functional monomer of the reactive functionalized polyolefin long-term dripping film.

[0029] 100 parts (mass) of ethylene-1-butene copolymer, butene content 5% (mass), in 60 The Co device is pre-irradiated with γ-rays, and the pre-irradiation dose is 80KGy.

[0030] The pre-irradiated ethylene-1-butene ...

Embodiment 3

[0033] 2 mol of polyether tetrahydric alcohol with a molecular weight of 488, 3 mol of xylene, and 2×10 p-dodecylbenzenesulfonic acid -3 mol, hydroquinone 2×10 -3 mol is added to the reactor equipped with stirrer, thermometer, reflux condenser, liquid dropping tube, nitrogen pouring tube and heating device, and 2 mol of maleic anhydride is dissolved in the liquid dropping tube filled with 6.075 mol of acetone , feed nitrogen, heat and stir, raise the temperature of the liquid in the reactor to 50°C, turn on the switch of the liquid dripping tube, start to add the liquid dropwise, the dropwise time is 55 minutes, after the dropwise addition, raise the temperature to 85°C, react for 8 hours, and end For the reaction, the temperature is lowered to 60°C, the pressure is reduced to -0.1MPa, and the solvent is removed to obtain a functional monomer of a reactive functionalized polyolefin long-lasting dripping film.

[0034] 100 parts (mass) of ethylene-1-octene copolymer with an oc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com