Terminal-hydroxyl organic phosphorus-nitrogen-sulphur ester content and preparation method thereof and flame-retardant polyester fiber POY(polyester pre-oriented yarn) made from terminal-hydroxyl organic phosphorus-nitrogen ester content

A flame-retardant polyester and esterification technology, which is applied in the field of flame retardants, can solve the problems of environmental pollution during the preparation process, difficulties in storage and use, and low content of functional elements, so as to overcome easy migration, be beneficial to environmental protection, and have a simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing a mercapto-terminated organic phosphorus-nitrogen-thioester compound, the steps are as follows:

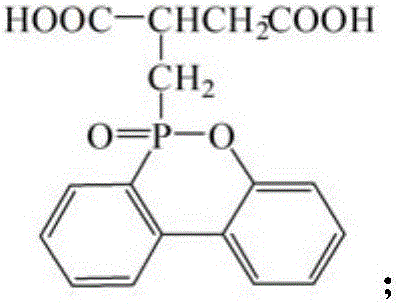

[0053] 1) The side group phosphorus-containing dicarboxylic acid and pentaerythritol are mixed with a molar ratio of 4:1, and the melt esterification reaction is carried out under the conditions of nitrogen protection and mechanical stirring. The stirring speed of the mechanical stirring is 300rpm, and the melting esterification reaction The temperature is 180°C, and the reaction time is 1 hour. After the reaction, the product is collected, dissolved, filtered and dried to obtain DAPER with a carboxyl group at the end. The structural formula of the side group phosphorus-containing dicarboxylic acid is:

[0054]

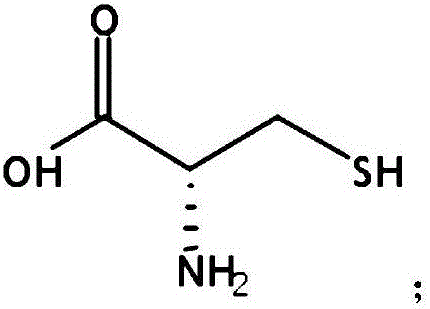

[0055] 2) Mix the thiol-terminated nitrogen-containing monocarboxylic acid and ethylene glycol at a molar ratio of 1:1, add 4-methylbenzenesulfonic acid, the molar ratio of the mercapto-terminal nitrogen-containing monocarboxylic acid to 4-...

Embodiment 2

[0067] A method for preparing a mercapto-terminated organic phosphorus-nitrogen-thioester compound, the steps are as follows:

[0068] 1) The side group phosphorus-containing dicarboxylic acid and pentaerythritol are mixed with a molar ratio of 4:1, and the melt esterification reaction is carried out under the conditions of nitrogen protection and mechanical stirring, and the stirring speed of the mechanical stirring is 336rpm. The temperature is 185°C, and the reaction time is 1 hour. After the reaction, the product is collected, dissolved, filtered and dried to obtain DAPER with a carboxyl group at the end. The structural formula of the side group phosphorus-containing dicarboxylic acid is:

[0069]

[0070] 2) Mix the mercapto-terminated nitrogen-containing monocarboxylic acid and propylene glycol at a molar ratio of 1:1, add 4-methylbenzenesulfonic acid, and the molar ratio of the mercapto-terminal nitrogen-containing monocarboxylic acid to 4-methylbenzenesulfonic acid i...

Embodiment 3

[0082] A method for preparing a mercapto-terminated organic phosphorus-nitrogen-thioester compound, the steps are as follows:

[0083] 1) The side group phosphorus-containing dicarboxylic acid and pentaerythritol are mixed with a molar ratio of 4:1, and the melt esterification reaction is carried out under the conditions of nitrogen protection and mechanical stirring, and the stirring speed of the mechanical stirring is 345rpm. The temperature is 188°C, and the reaction time is 1 hour. After the reaction, the product is collected, dissolved, filtered and dried to obtain DAPER with a carboxyl group at the end. The structural formula of the side group phosphorus-containing dicarboxylic acid is:

[0084]

[0085] 2) Mix thiol-terminated nitrogen-containing monocarboxylic acid and 1,4-butanediol at a molar ratio of 1:1, add 4-methylbenzenesulfonic acid, mercapto-terminated nitrogen-containing monocarboxylic acid and 4-methylbenzenesulfonic acid The molar ratio of the acid is 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com