A kind of thermoplastic starch plasticized by polyionic liquid and preparation method thereof

A technology of polyionic liquid and thermoplastic starch, applied in the field of starch deep processing, can solve problems such as easy migration, and achieve the effect of overcoming easy migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A thermoplastic starch plasticized by polyionic liquid, the thermal processing temperature is 180°C, the tensile strength is 10.37MPa, the elongation at break is 2.25%, the mobility of plasticizer is 0.59%, and the melt index is 6.2g / 10min .

[0036] The preparation method of the thermoplastic starch plasticized by the above-mentioned polyionic liquid is:

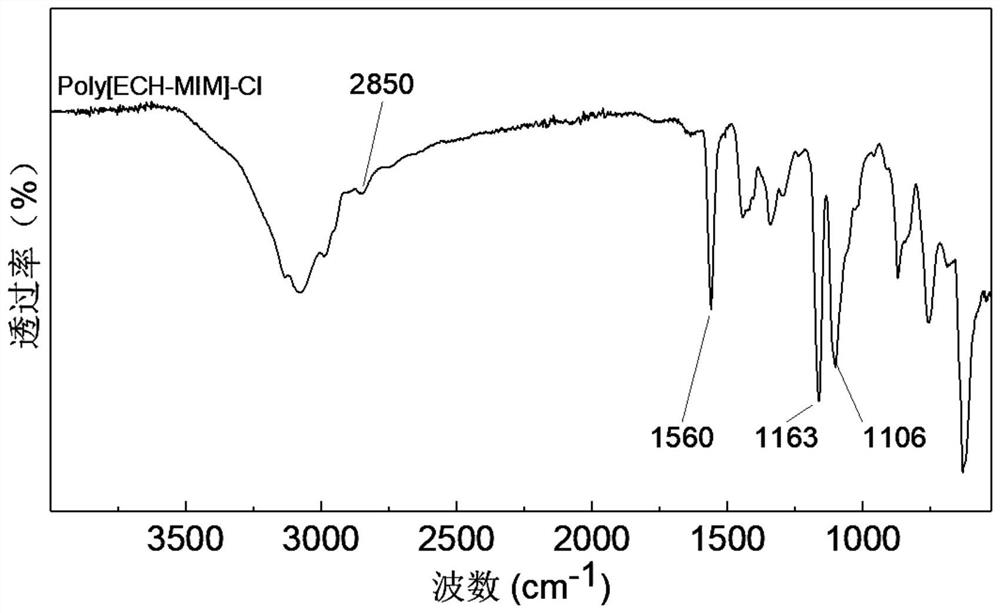

[0037] Step a: Weigh cornstarch and polyionic liquid Poly[ECH-MIM]-Cl, 9g and 1g respectively, and set aside;

[0038] Step b: Dissolve 9g of cornstarch in 50mL of deionized water, 1g of polyionic liquid in 50mL of deionized water, then mix the two solutions evenly, and set aside;

[0039] Step c: uniformly stir the mixed solution in step b at a speed of 200 r / min at 100°C, and time it for 60 minutes;

[0040] Step d: drying the mixture obtained in step c at 80° C. for 48 hours to remove moisture to obtain a solid product;

[0041] Step e: Set the heating temperature of the flat vulcanizer to 180°C and the pressur...

Embodiment 2

[0043] A thermoplastic starch plasticized with polyionic liquid, its thermal processing temperature is 170°C, its tensile strength is 4.91MPa, its elongation at break is 6.81%, its plasticizer mobility is 0.33%, and its melt index is 6.2g / 10min .

[0044] The preparation method of the thermoplastic starch plasticized by the above-mentioned polyionic liquid is:

[0045] Step a: Weigh cornstarch and polyionic liquid Poly[ECH-MIM]-Cl, 4g and 6g respectively, and set aside;

[0046] Step b: Dissolve 4g of cornstarch in 50mL of deionized water, 6g of polyionic liquid in 50mL of deionized water, then mix the two solutions evenly, and set aside;

[0047] Step c: uniformly stir the mixed solution in step b at a speed of 250 r / min at 95°C, and time it for 60 minutes;

[0048] Step d: drying the mixture obtained in step c at 80° C. for 72 hours to remove moisture to obtain a solid product;

[0049] Step e: Set the heating temperature of the flat vulcanizer to 170°C and the pressure t...

Embodiment 3

[0051] A thermoplastic starch plasticized by polyionic liquid, the thermal processing temperature is 180°C, the tensile strength is 7.83MPa, the elongation at break is 4.33%, the plasticizer mobility is 0.84%, and the melt index is 6.2g / 10min .

[0052] The preparation method of the thermoplastic starch plasticized by the above-mentioned polyionic liquid is:

[0053] Step a: Weigh cornstarch and polyionic liquid Poly[ECH-MIM]-Cl, 7g and 3g respectively, and set aside;

[0054] Step b: Dissolve 7g of cornstarch in 50mL of deionized water, dissolve 3g of polyionic liquid in 50mL of deionized water, mix the two solutions evenly, and set aside;

[0055] Step c: uniformly stir the mixed solution in step b at a speed of 150 r / min at 100°C, and time it for 90 minutes;

[0056] Step d: drying the mixture obtained in step c at 90°C for 48 hours to remove moisture to obtain a solid product;

[0057] Step e: Set the heating temperature of the flat vulcanizer to 180°C and the pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com