Pre-stress vibrating diaphragm

A pre-stressed, thin-film technology, applied in the direction of flat diaphragm, diaphragm fixing/tightening, diaphragm structure, etc., to achieve the effect of improving sound quality, small phase distortion, and reducing harmful vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0037] To facilitate understanding, before describing specific embodiments, a brief introduction to the structure of the present invention will be given.

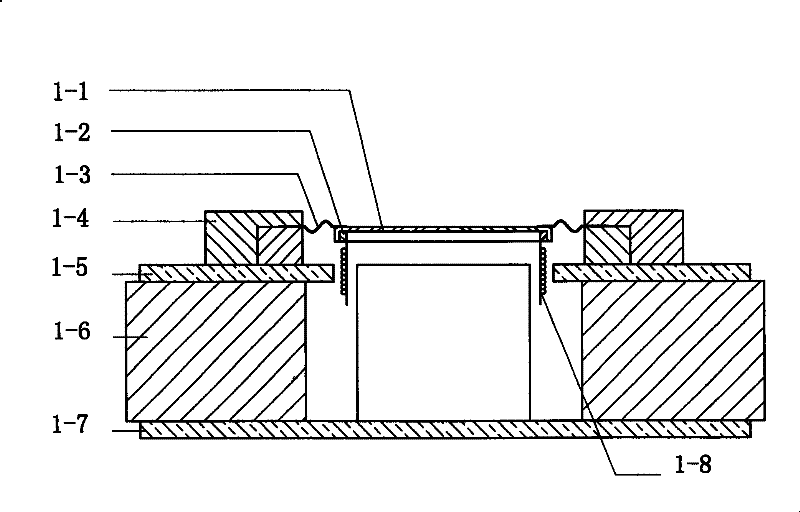

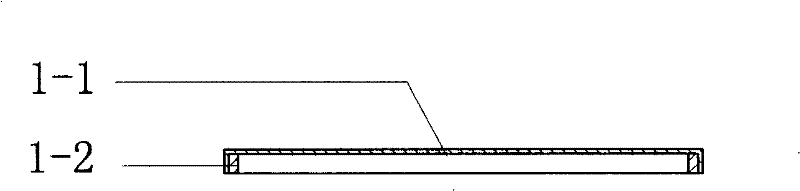

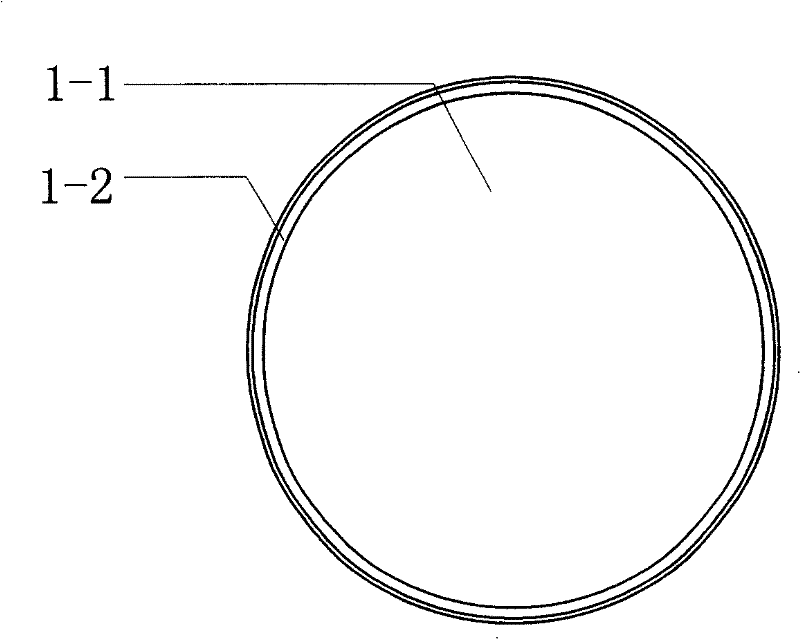

[0038] figure 1 Shown is a loudspeaker of the present invention, including a rigid diaphragm frame 1-2 connected to the voice coil 1-8, the diaphragm 1-1 is a tensioned pre-stressed diaphragm, the diaphragm frame 1-2 Fixed tension pre-stressed film. The frame 1-2 of the pre-stressed diaphragm is connected to the voice coil 1-8, and the edge of the pre-stressed diaphragm is connected to the bracket 1-4 through an elastic support 1-3. The functions and connection methods of other components are the same as those of traditional speakers. The bracket 1-4 is connected to the magnetic conductive plate 1-5, the magnet 1-6 and the magnetic conductive column 1-7.

[0039] Such as Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com