Prepn process of 4-amino-2-trifluoromethyl benzonitrile

A technology of trifluoromethyl benzonitrile and trifluoromethyl fluorobenzene, applied in the field of preparing 4-amino-2-trifluoromethyl benzonitrile, can solve the problem of high production cost, many raw materials, many by-products, etc. problems, to achieve the effect of low production cost, simple process and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

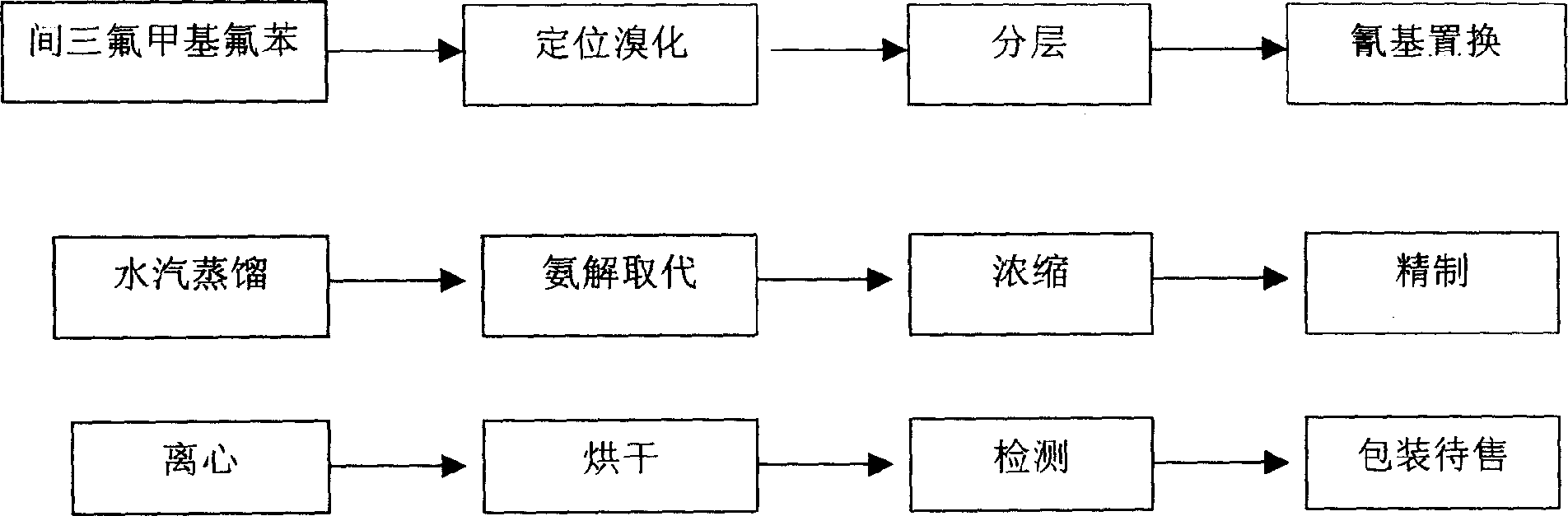

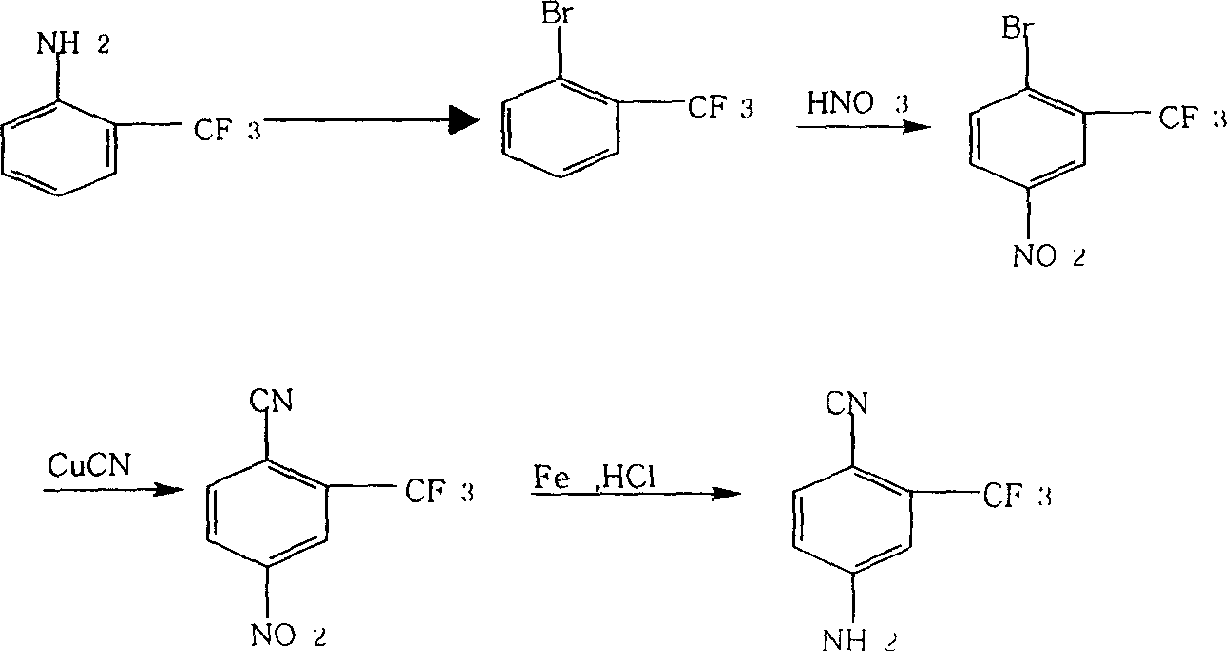

Method used

Image

Examples

Embodiment 1

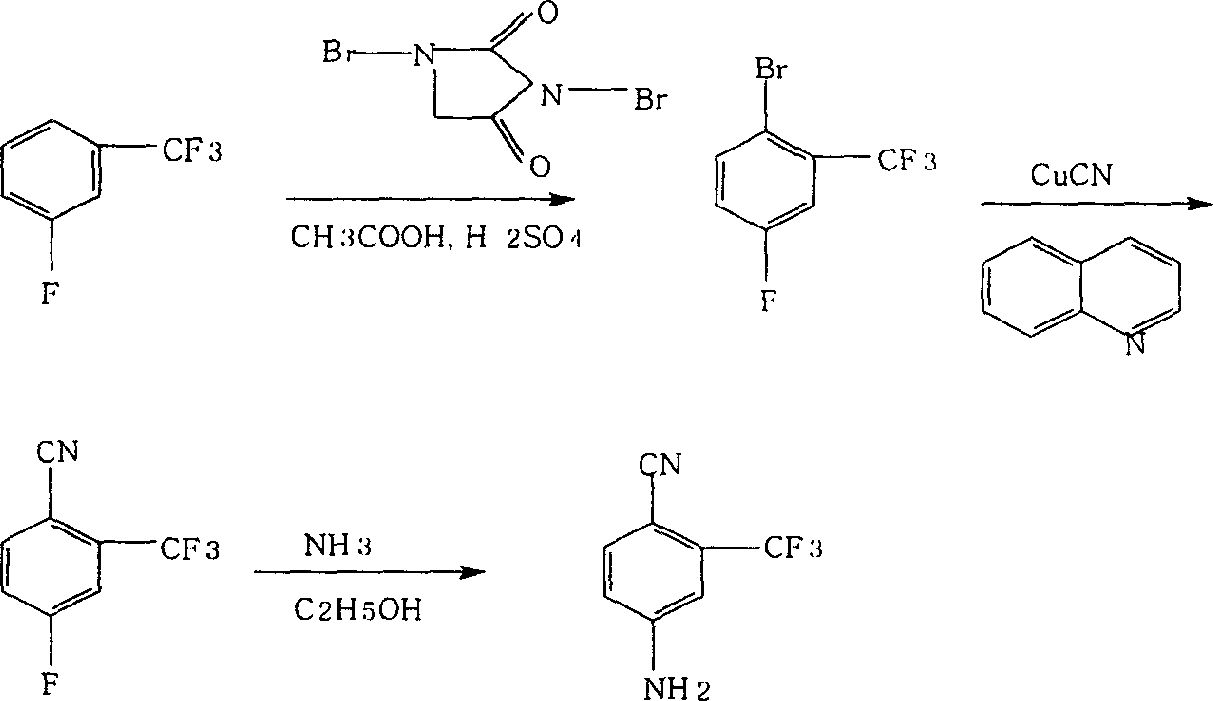

[0017] The first step of positioning bromination: put 200kg m-trifluoromethylfluorobenzene, 80kg glacial acetic acid, and 35kg concentrated sulfuric acid into the reaction pot, mix and stir, heat up and reflux, add 188kg dibromohydantoin in batches, react for 6 hours, and store on ice Wash with water to obtain 260kg of 4-fluoro-2-trifluoromethyl bromide, with a content of more than 98%;

[0018] The second step of cyano group replacement: Take 250kg quinoline and 106kg cuprous cyanide and add dropwise the 4-fluoro-2-trifluoromethylbromobenzene obtained in the first step under the state of stirring and reflux. Distill 200kg of 4-fluoro-2-trifluoromethylbenzonitrile;

[0019] The third step of ammonolysis and substitution: dissolve the 4-fluoro-2-trifluoromethylbenzonitrile obtained in the second step in 350 kg of ethanol, feed in 27 kg of liquid ammonia, and heat up to 120°C for 8 hours to obtain 4- Amino-2-trifluoromethylbenzonitrile crude product 185kg, finally obtains finis...

Embodiment 2

[0022] The first step of positioning bromination: put 250kg of m-trifluoromethylfluorobenzene, 100kg of glacial acetic acid, and 44kg of concentrated sulfuric acid into the reaction pot, mix and stir, heat up and reflux, add 235kg of dibromohydantoin in batches, react for 6.5 hours, and store on ice Wash with decomposed water to obtain 4-fluoro-2-trifluoromethyl bromobenzene;

[0023] The second step of cyano replacement: take 310kg of quinoline and 132kg of cuprous cyanide and add dropwise the 4-fluoro-2-trifluoromethylbromobenzene obtained in the first step under the state of stirring and reflux. 4-fluoro-2-trifluoromethylbenzonitrile is distilled off;

[0024] The third step of ammonolysis and substitution: dissolve the 4-fluoro-2-trifluoromethylbenzonitrile obtained in the second step in 440 kg of ethanol, pass through 34 kg of liquid ammonia, and heat up to 122 ° C for 10 hours to obtain 4- Amino-2-trifluoromethylbenzonitrile crude product 211kg, finally obtains finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com