Light-reflector and planar light source using same

A technology of light reflector and reflectivity, applied in the direction of light guide, optics, optical components, etc., can solve the problems of peeling, peeling, peeling of white polyolefin film surface, etc., and achieve excellent processability, excellent optical properties, and good brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

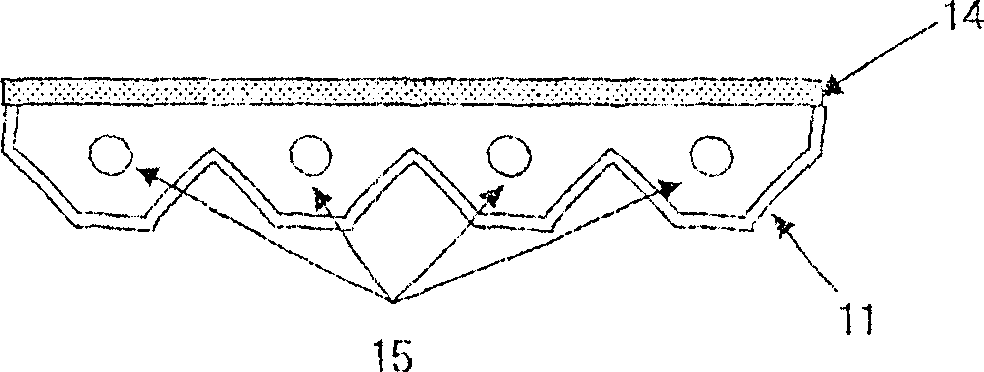

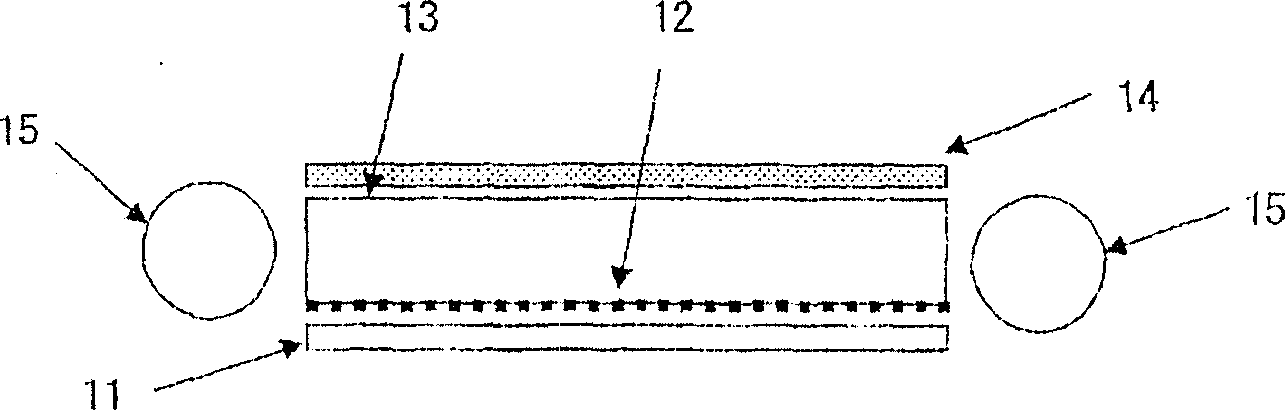

[0062] Composition (A) and composition (B) obtained by mixing the materials described in Table 1 according to the ratio shown in Table 2 were melted at 250°C using 3 extruders (2 for composition (B)) kneading. Then, it is supplied to a co-extrusion die, and (B) is laminated on both sides of (A) in the die, extruded as a sheet, and cooled to about 60°C with a cooling roll to obtain (B) / (A) / (B) laminate.

[0063] The above-mentioned laminate was reheated to 145° C., longitudinally stretched by utilizing the difference in linear speed of a plurality of roll groups, and then reheated to about 150° C. and transversely stretched by a tenter. Next, after performing softening treatment at 160°C, it was cooled to 60°C, and a laminated film with a three-layer structure was obtained after cutting off burrs. The stretch ratios in the longitudinal and transverse directions and the thickness of each layer are shown in Table 2. The above laminated film was used as a light reflector.

Embodiment 2~5

[0065] The composition (A) obtained by mixing the materials described in Table 1 according to the compounding ratio shown in Table 2 was melt-kneaded at 250° C. using an extruder. Then it is extruded in the form of flakes and cooled to about 60°C with a cooling roll to obtain flakes. After the above-mentioned sheet was heated to 145°C, it was longitudinally stretched using the difference in line speed of a plurality of roller groups.

[0066]The composition (B) obtained by mixing the materials described in Table 1 according to the ratio shown in Table 2 was melt-kneaded using two extruders, extruded (B) in the mold as the outside and laminated on the above to obtain Both sides of the sheet were stretched to obtain a (B) / (A) / (B) laminate. Next, the laminate was heated again to 160° C. and stretched transversely with a tenter.

[0067] Then, after performing a softening treatment at 160°C, it was cooled to 60°C, and a laminated film with a three-layer structure was obtained af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com