Multi-stage porous titanium-silicon zeolite preparation method and its uses in catalytic oxidation

A titanium silicalite, catalytic oxidation technology, applied in the direction of crystalline aluminosilicate zeolite, molecular sieve catalyst, chemical equipment and methods, etc., can solve the problems of difficult control, wide distribution of titanium silicalite mesopore size, etc., and achieve good catalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of powdery ordered mesoporous carbon material: take 5g powder Al / SBA-15 with a silicon-aluminum ratio of 20 (using P123 as a template), add furan methanol according to the equal volume impregnation method, and polymerize in an oven at 90°C After 12 hours, the obtained polymer was carbonized under the protection of high-purity nitrogen. The carbonization program was from room temperature to 150°C at a heating rate of 1°C / min; Let cool to room temperature. The resulting product was refluxed overnight in 5% HF acid to remove the templated SBA-15.

Embodiment 2

[0027] Preparation of bulk ordered mesoporous carbon material: the powdered Al / SBA-15 in Example 1 was replaced with bulk Al / SBA-15, and other methods were similar to Example 1.

Embodiment 3

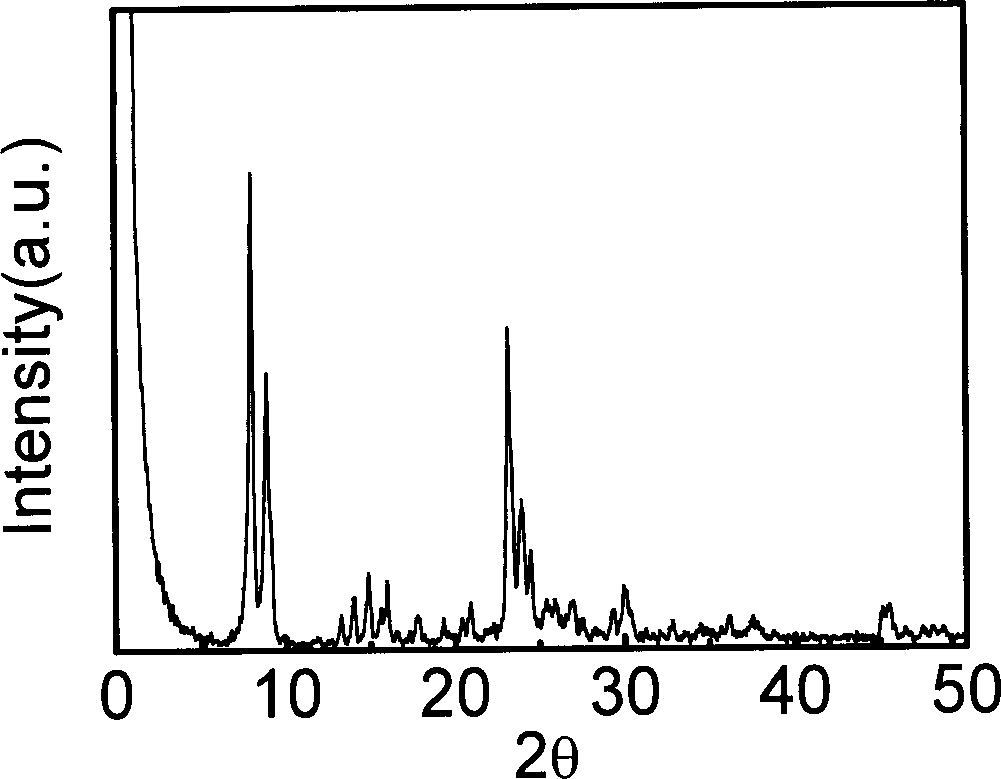

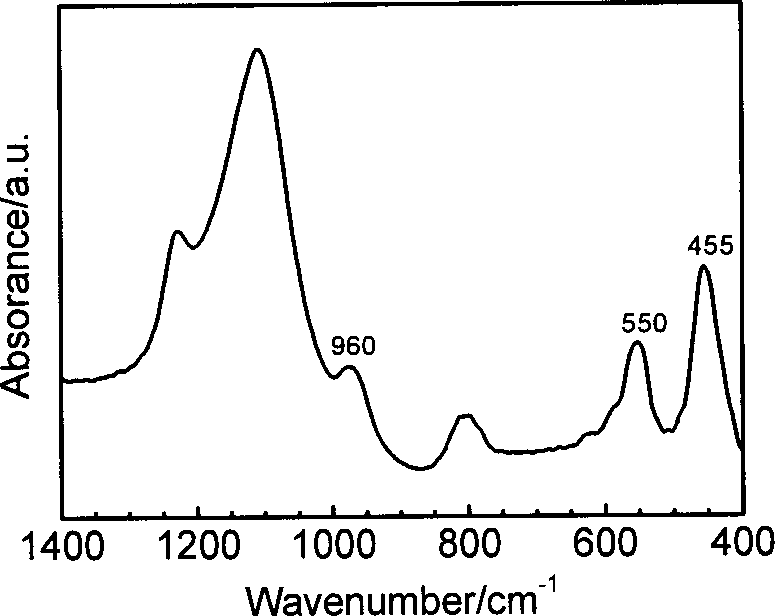

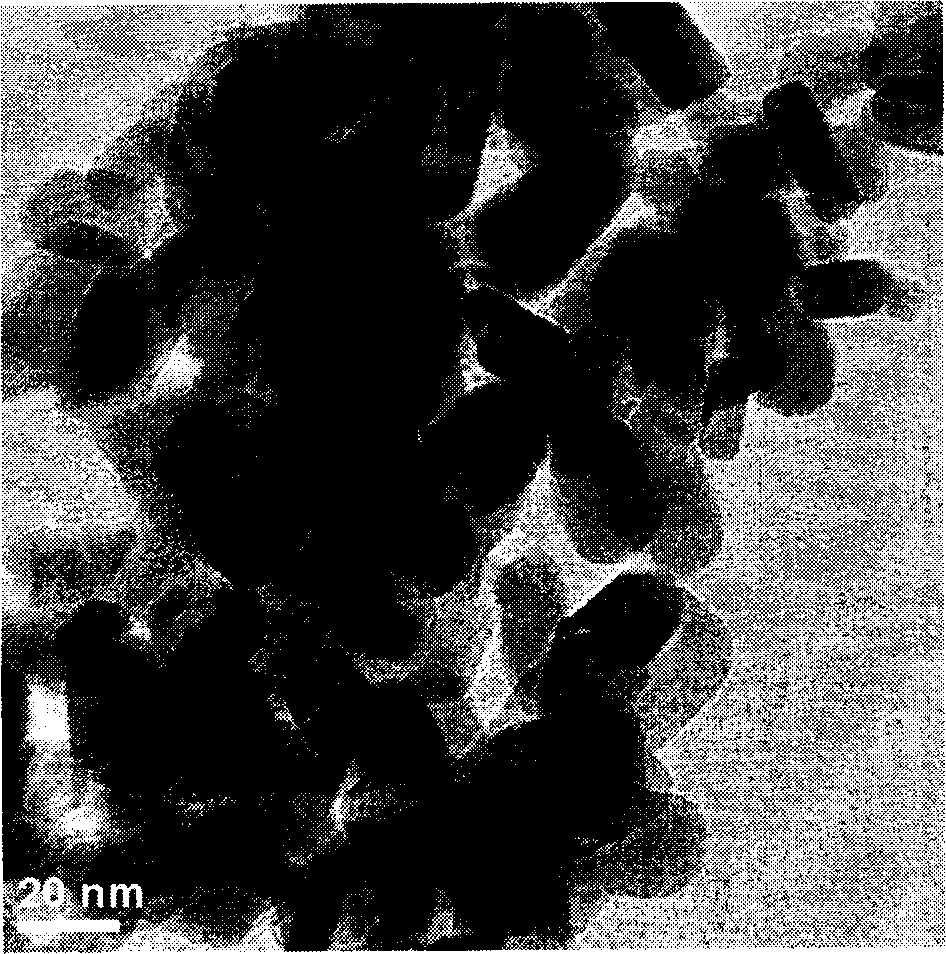

[0029] Synthesis of mesoporous TS-1: take 4 g of the ordered mesoporous carbon material synthesized in Example 1, add a pre-mixed solution containing tetrapropylammonium hydroxide, ethanol, and water according to the equal volume impregnation method, and let the ethanol Volatile, then press C / SiO 2 The mass ratio of 2:1 was added dropwise to the mixed solution of ethyl orthosilicate and butyl titanate. The material ratio of each raw material is SiO 2 / TiO 2 / TPAOH / H 2 O 1:0.0125:0.2:2, aging at room temperature for 3h, and then crystallized in a Teflon-lined autoclave at 170°C for 48h, the resulting solid was washed with water, filtered, dried at 120°C for 4h, and calcined at 550°C for 4h to obtain a white Mesoporous TS-1 powder. The obtained product was characterized by X-ray diffraction, Fourier transform infrared spectroscopy, ultraviolet-visible spectroscopy, nitrogen adsorption, transmission electron microscopy, etc., which proved that the product contained a signific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com