Automated comprehensive treatment system and method for biogas production by utilizing garbage, sewage and plant

A comprehensive treatment and sewage technology, applied in the direction of biochemical equipment and methods, biological sludge treatment, biological organic part treatment, etc., can solve the difficulty of sludge separation, inability to deal with various sewage, and difficulty in distinguishing batches of incoming and outgoing materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

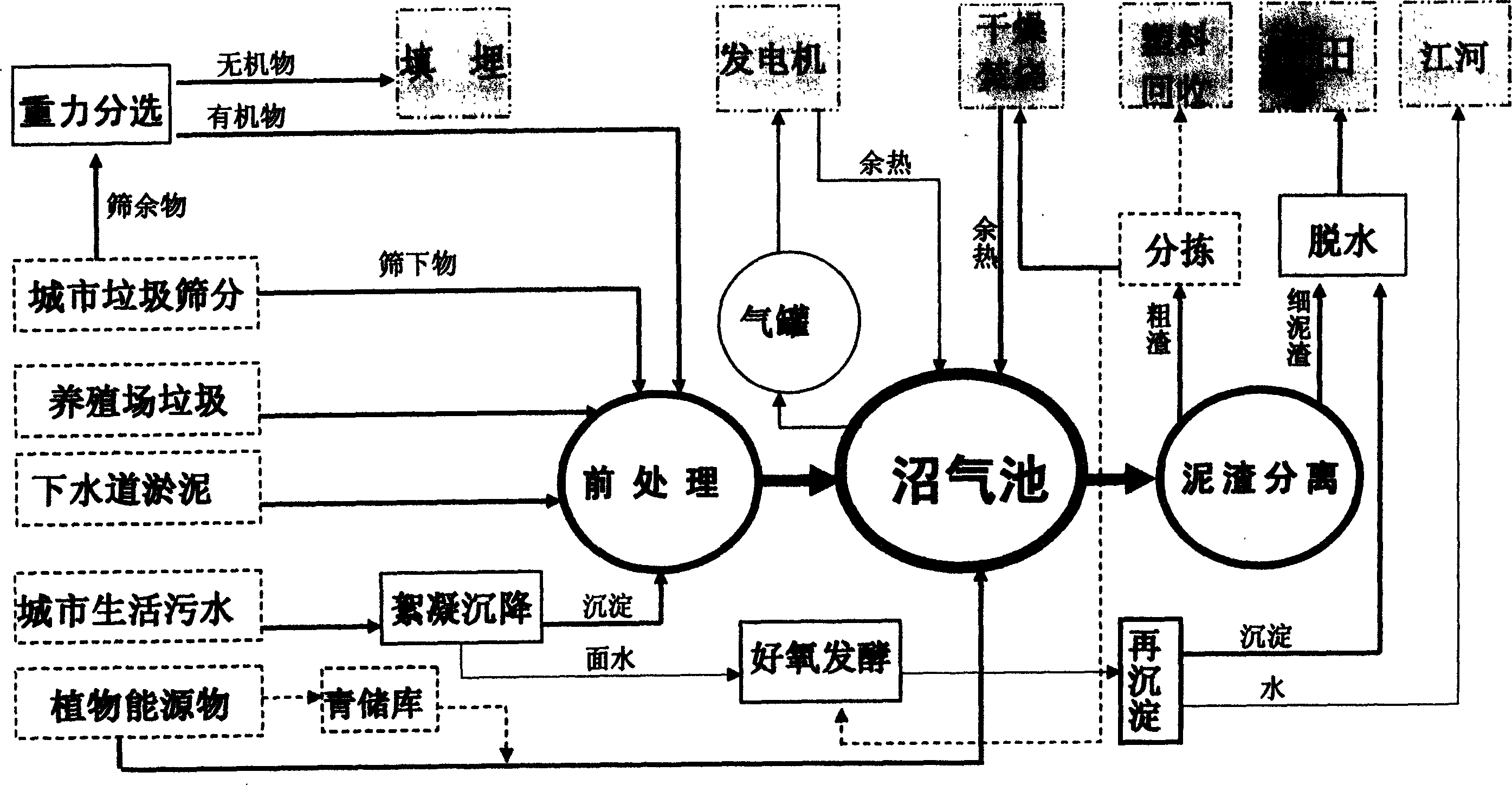

[0022] The main system of this comprehensive system is composed of urban waste classification system, farm waste system, factory waste waste liquid system that can be degraded by microorganisms, urban sewage system, plant production of clean energy, sewage "aerobic" treatment and other supporting subsystems; Only one subsystem can be selected to form a complete set with the main system. To make up for the insufficiency that the existing treatment technologies such as garbage and sewage cannot be fully centralized, large-scale, automatic and comprehensive treatment. At the same time, it can also save a lot of manpower and material resources, reduce processing costs, and generate certain economic benefits.

[0023] The present invention adopts "container" to load material into the biogas digester and ferment in the way of flowing water production line, which solves the problem of mixed new and old materials in the current fermentation tank, insufficient fermentation, stones and ...

Embodiment 2

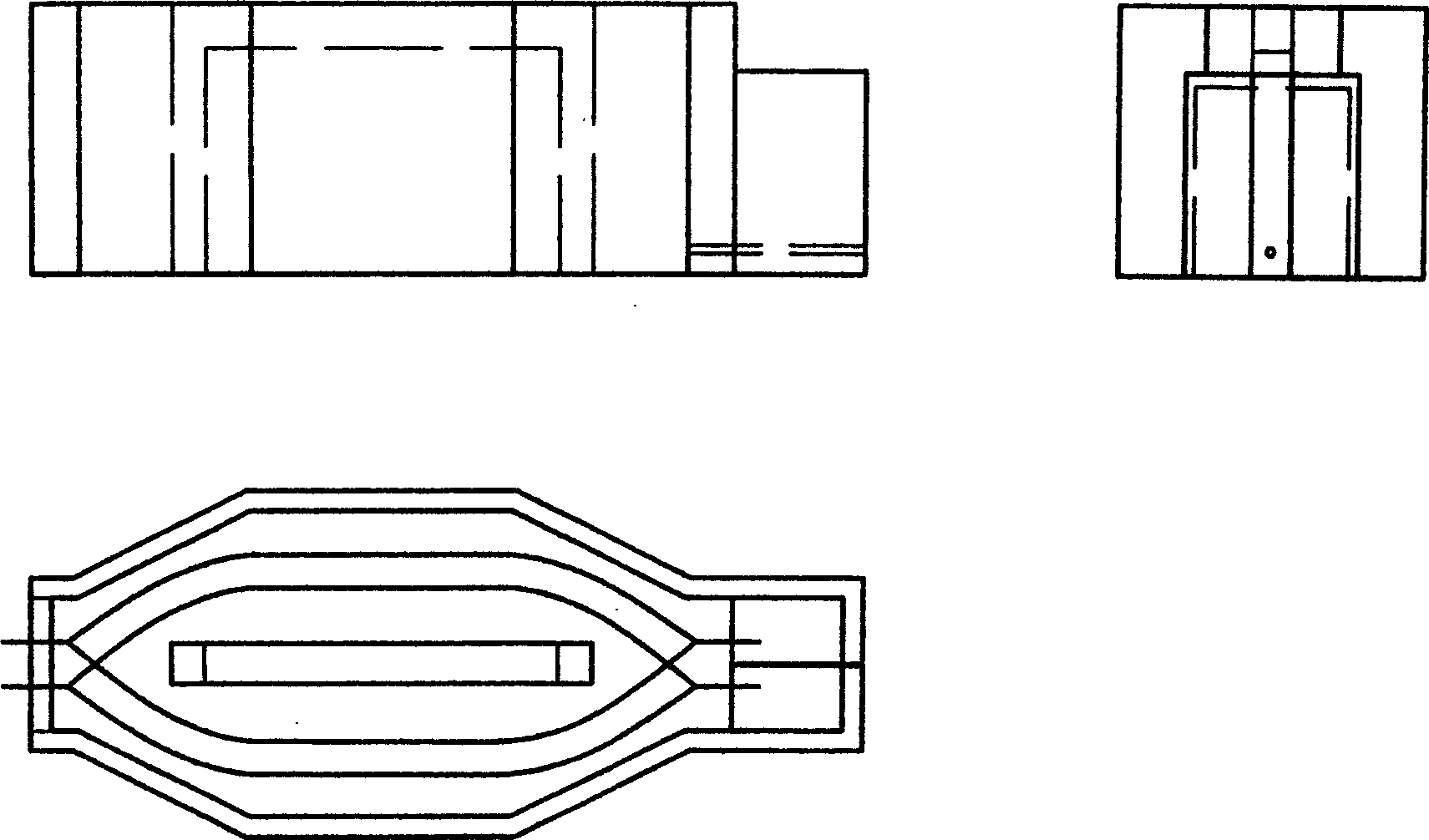

[0036] The main process is the same as that of Embodiment 1, except that the hanging basket is cancelled, and the structure of a carrier vehicle is adopted, so that the structures of the pretreatment pond and biogas digester are different.

[0037] The pretreatment pool is a tunnel structure. The characteristics are: the "container" is placed on the carrier vehicle and pushed into the pool, adding quicklime into the pool, closing the front and rear doors, and passing in steam for pre-treatment. After the treatment, the car and the "container" are sent to the biogas digester together.

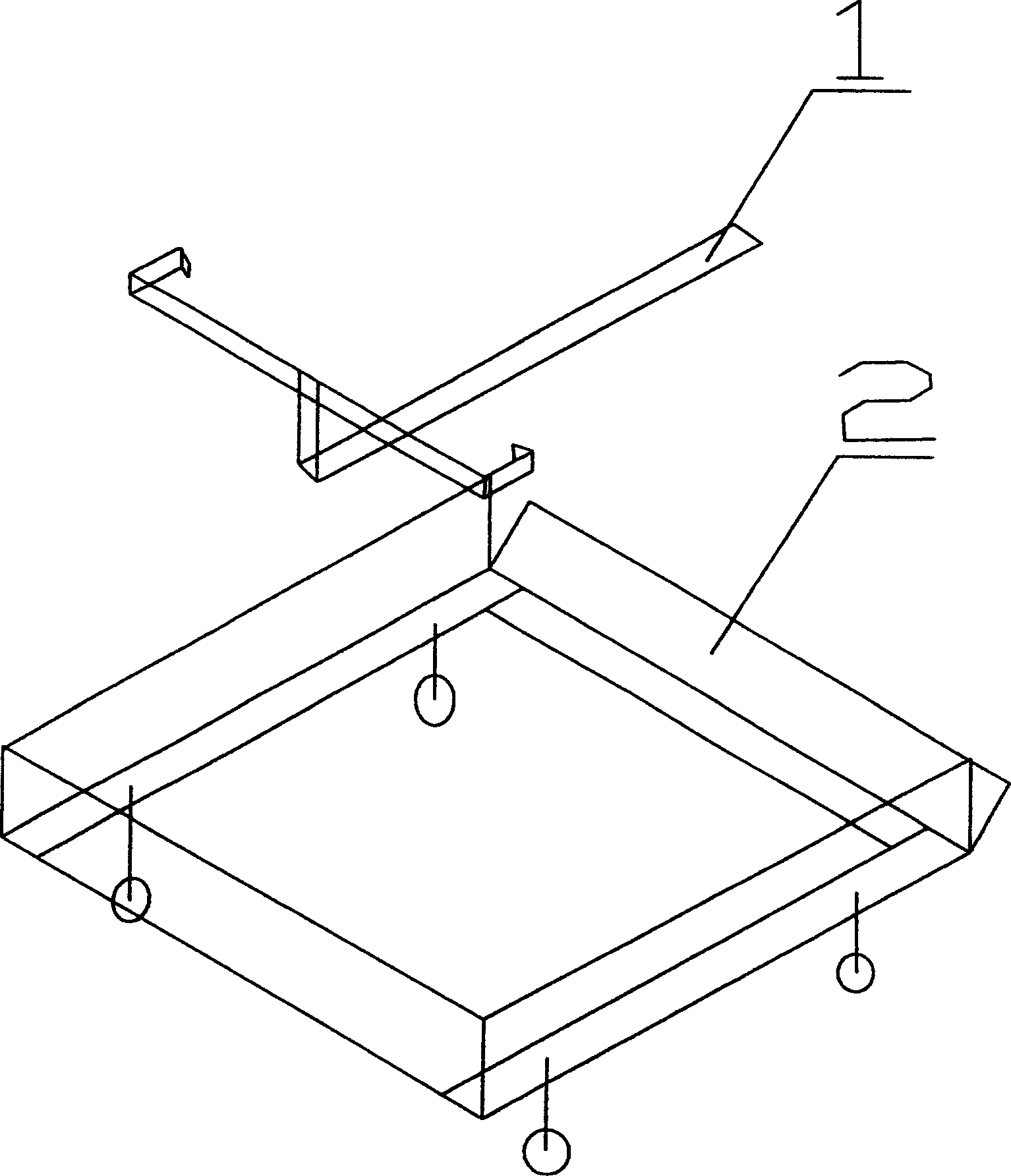

[0038] The biogas digester is a cuboid pool, and the pool is built underground, and it should be built deeper from the ground in cold regions. Biogas storage tanks or farms can be built above the biogas digester. Biogas digesters are suitable for small towns with a lot of land and not much disposal. Its characteristics are: the biogas digester is built with concrete or other materials, and th...

Embodiment 3

[0040] Implementation example 3: The biogas digester in this implementation is a newly built pond. After half a year of use, the top leaked, and the top cover was removed for reconstruction. Digester capacity 400m 3 , 3 engineering plastic pulleys are installed in the biogas digester, the feed inlet is discarded, and 1 pulley is installed at the discharge outlet, and a nylon rope is placed on the wheel, and many waste plastic barrels with an aperture of 3 are hung on the rope. Single barrel body set 0.6 cubic meters. By manually dragging the nylon rope, circular fermentation and discharge are realized. The operating temperature is normal temperature, the gas production of the biogas digester is 1 to 2 times higher than in the past, and there is still 1 to 2 times the gas production potential. Among them, there is a special box with a mouth size of 1.5 x 1.5 x 1.5 meters. After fermentation is run in the pool, the box is opened for inspection, and the fermentation effect is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com