Plasma cleansing apparatus that eliminates organic and oxidative contaminant and may effectively dissipate heat and eliminate exhaust gas and integrated system for the same

A plasma cleaning and plasma technology, applied in the direction of plasma, cleaning methods and appliances, discharge tubes, etc., can solve problems affecting the safety of workers, damaging materials, hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

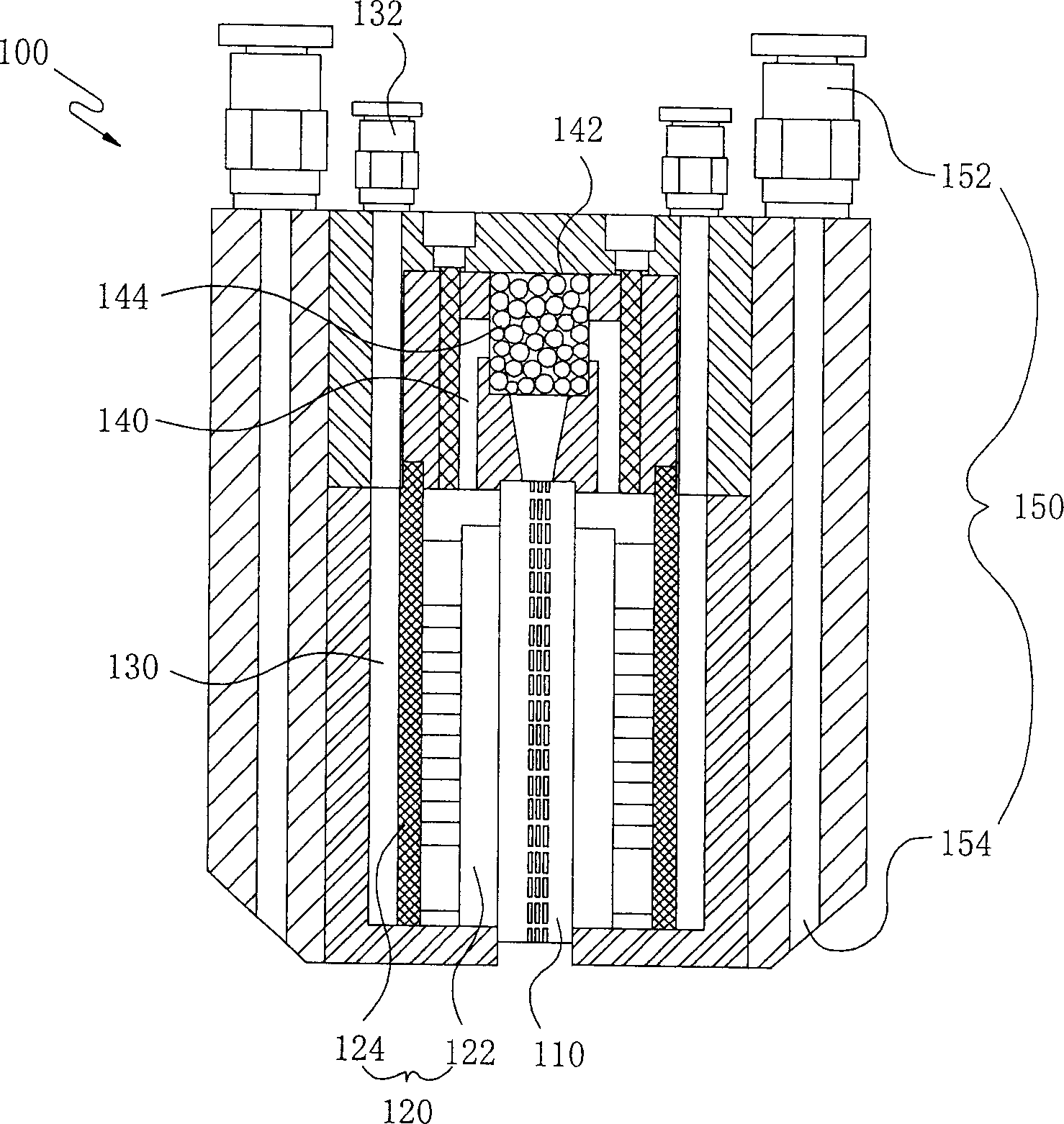

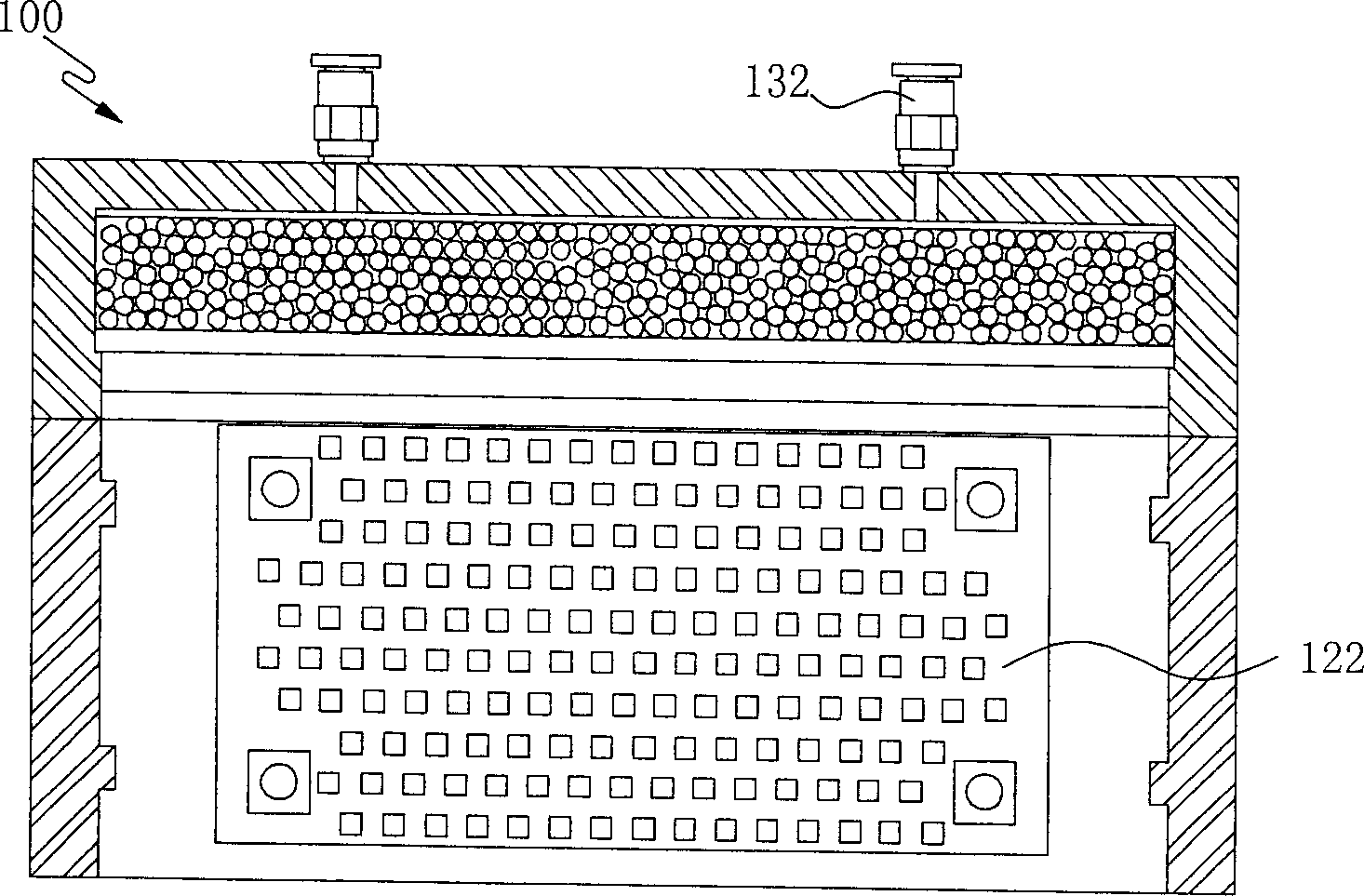

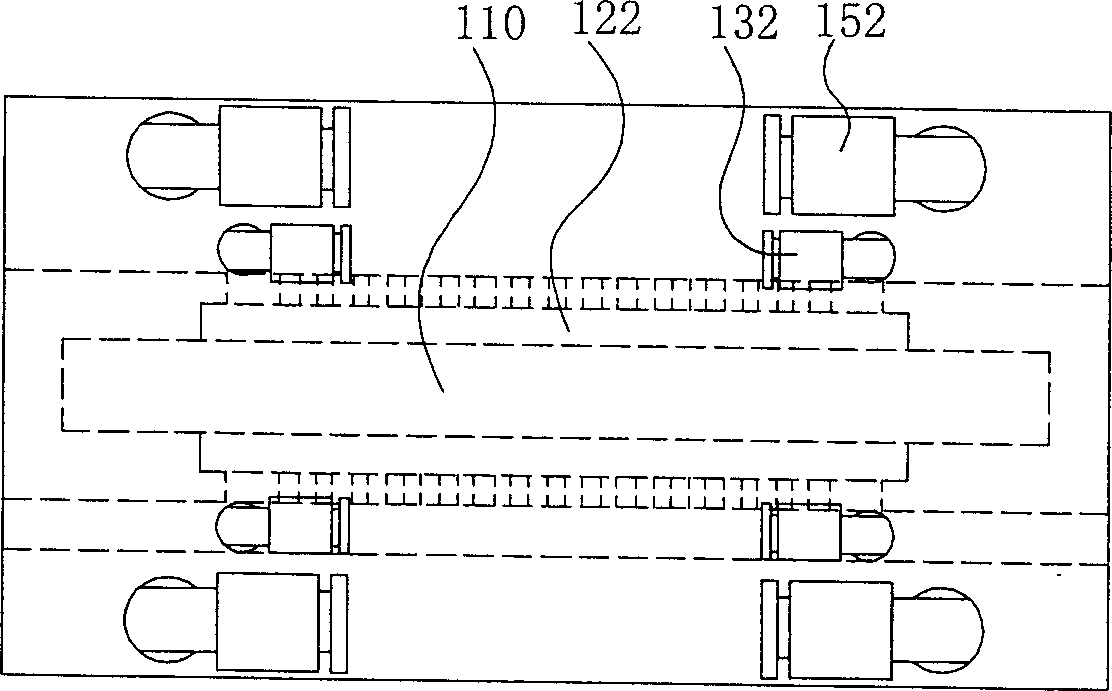

[0047] see Figure 1 to Figure 3 , The plasma cleaning device 100 of the present invention includes: an electrode part 110 , a heat radiation part 120 , a source gas introduction part 130 , a source gas supply guide part 140 , and an intake and exhaust part 150 .

[0048] The plasma cleaning device 100 may be an atmospheric plasma cleaning device.

[0049] The electrode parts 110 are arranged in the center of the plasma cleaning device 100 at intervals. Preferably, the electrode parts 110 are arranged in parallel to make the plasma heat evenly. When the number of electrodes arranged is singular, for example, when the electrode part 110 is formed of three electrodes, the electrode in the center is a high-voltage electrode, and the electrodes on both sides are grounded. Because the power supply of the electrode is a high-voltage power supply, it is not possible to use a general voltage directly. If a general power supply is used, it is necessary to add a power supply device wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com