Plane luminous display with high-colority contrast structure and its making process

A luminescent display and chromaticity contrast technology, which is applied in display technology, microelectronics science and technology, vacuum science and technology, and in the field of nano science and technology, can solve the problems of increasing the blackness of the display and weakening the high brightness of the displayed image, etc., and achieves low production cost , Reduce production costs, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

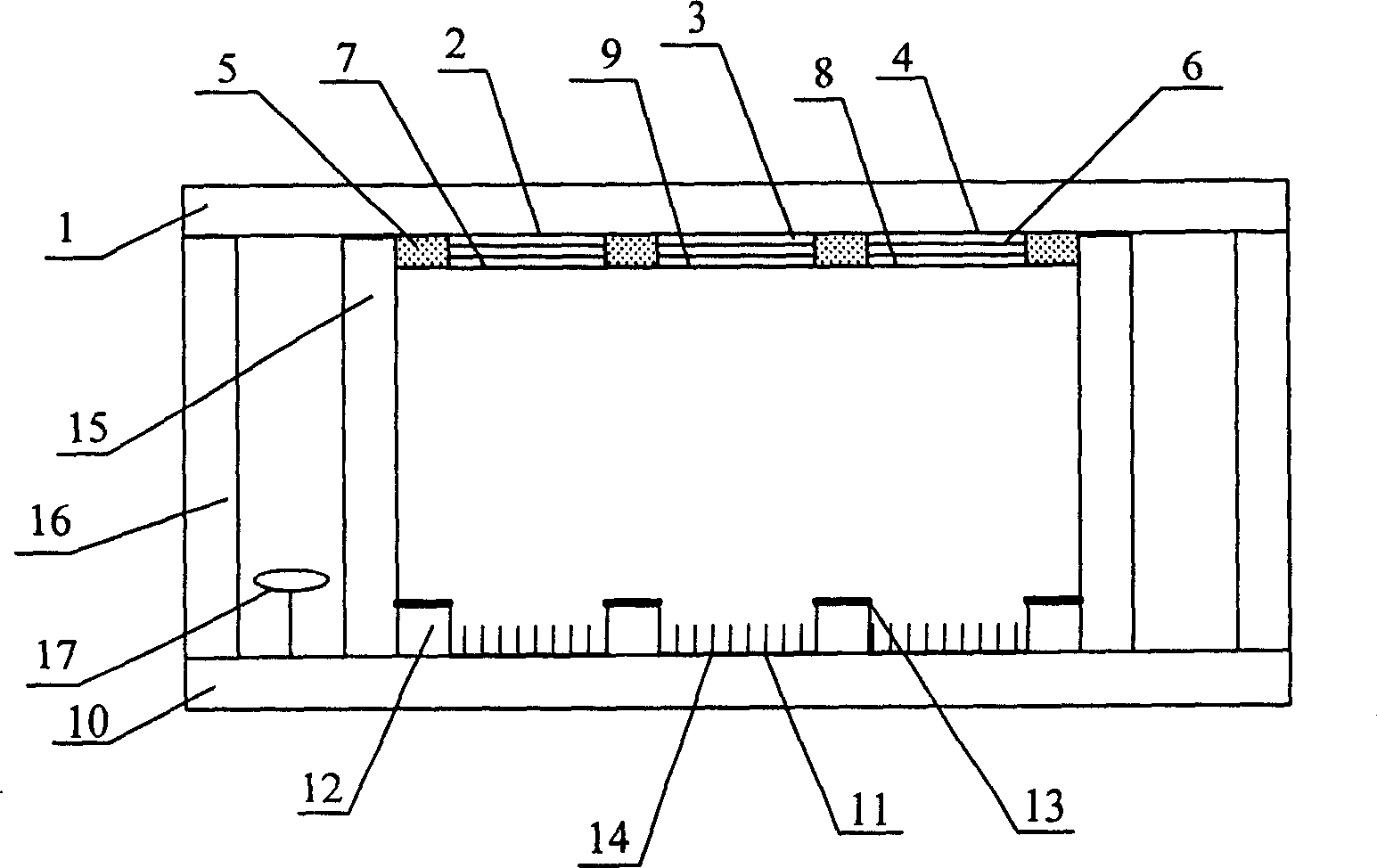

[0036] The present invention comprises the sealed vacuum chamber that is made of anode substrate glass [1], cathode substrate glass [10] and surrounding glass frame [16], cathode conductive strip [11] and Printed carbon nanotube cathode [14], control grid for controlling electron emission [13], phosphor layer prepared on anode substrate glass [1], support wall structure [15] and its attached getter [ 16] Element characterized in that a high chromatic contrast structure is mounted on the anode panel.

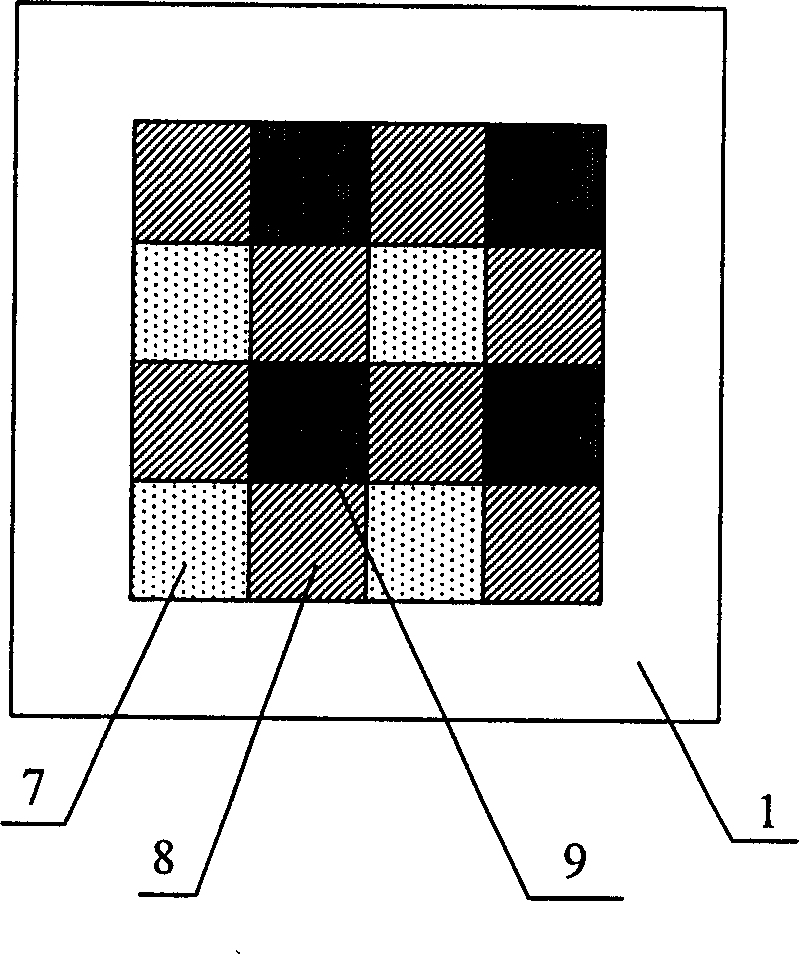

[0037] The high chroma contrast structure includes an anode substrate [1], a red filter layer [2], a blue filter layer [3] and a green filter layer [4] arranged on the anode substrate [1] , the anode insulating layer [5] that is located in the vacant position between the red filter layer [7], ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com