Polymyxin E separation preparation method

A technology for polymyxin and fermentation broth, applied in the field of separation and preparation of polymyxin E, can solve the problems of high cost, pollution, low yield and the like, achieve broad economic effects, reduce pollution, and simplify the effect of extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

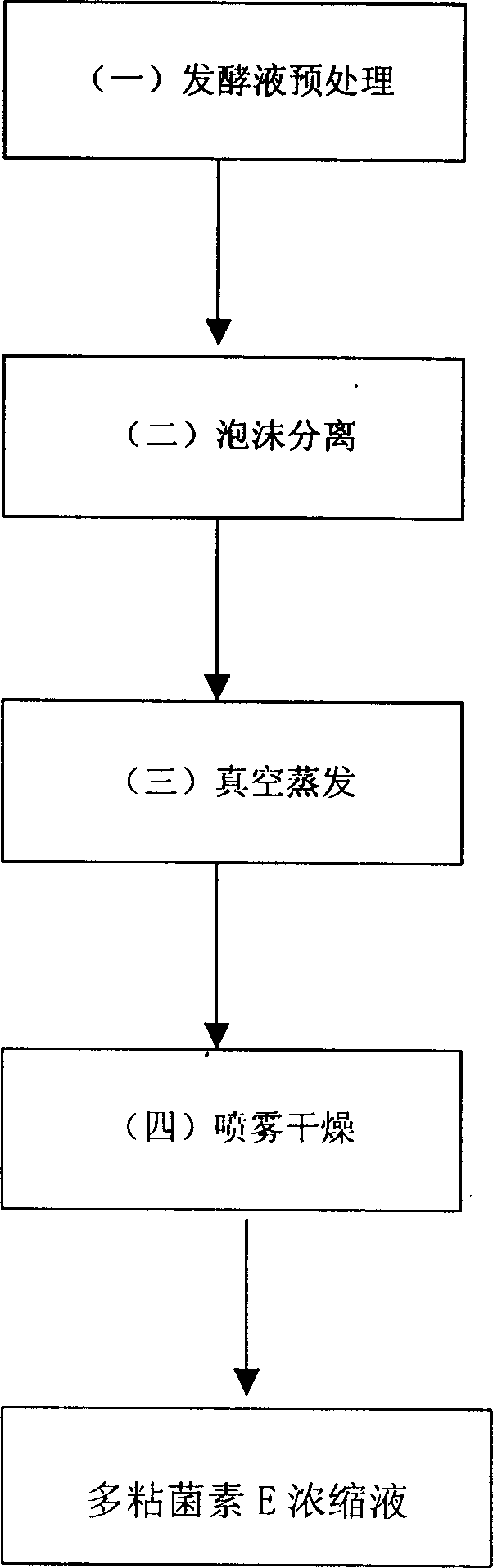

Method used

Image

Examples

Embodiment 1

[0022] a. Pretreatment of fermentation broth:

[0023] The fermented liquid containing polymyxin E produced by Bacillus Pollus Polymyxa Var Colistinus (the fermented liquid was purchased from Schreck (Tianjin) Biotechnology Co., Ltd., the same as the following examples) was used in oxalic acid solution Adjust the pH value to 3.5, heat at 80°C for 30 minutes, and filter the acidified fermentation broth through a plate frame for 2.5 hours. The yield of polymyxin E was 96%.

[0024] b. Foam separation

[0025] Use a bubble column for batch separation at a temperature of 50°C, a pH of 4.5, and a superficial gas velocity of 1×10 -3 m / s, the foam breaking method adopts a mechanical method, and the foam is broken by stirring. The operation time of one cycle is 2.5 hours, and a high-concentration polymyxin E foam breaking liquid is obtained, and its concentration factor is 14. The yield of polymyxin E was 90%.

[0026] c. Vacuum evaporation

[0027] The foam breaking solution was...

Embodiment 2

[0031] a. Pretreatment of fermentation broth:

[0032] The fermentation broth containing polymyxin E produced by Bacillus polymyxa colistin variants is adjusted to pH 2.5 with oxalic acid solution, heated at 90°C for 20 minutes, and the acidified fermentation broth is filtered through a plate frame for 2 hours . The yield of polymyxin E was 94%.

[0033] b. Foam separation

[0034] Use a bubble column for batch separation at a temperature of 30°C, a pH of 3.5, and a superficial gas velocity of 1×10 -4 m / s, the foam-breaking method adopts the method of adding an organic solvent, adds dehydrated alcohol by the spray flow of 2% of the foam-breaking liquid amount, and a cycle operation time is 3.0 hours to obtain a high-concentration polymyxin E foam-breaking liquid, which The concentration factor is 13. The yield of polymyxin E was 90%.

[0035] c. Vacuum evaporation

[0036] The foam breaking solution was evaporated in vacuo. The pH is 5.0, the temperature is 80°C, and th...

Embodiment 3

[0040] In the foam separation step in b, the foam breaking method adopts the method of adding an organic solvent, and acetone is added to the 1% spray flow of the foam breaking liquid amount, and other steps are the same as in Example 2. Step b obtains a high-concentration polymyxin E foam-breaking liquid, and its concentration factor is 14. The yield of polymyxin E was 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com