Method for preparing film material of metal hafnium

A thin film material and metal technology, which is applied in the field of high melting point metal hafnium thin film material, which is difficult to purify, and can solve the problems of increasing contact resistance, high melting point, reducing film crystal quality and conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

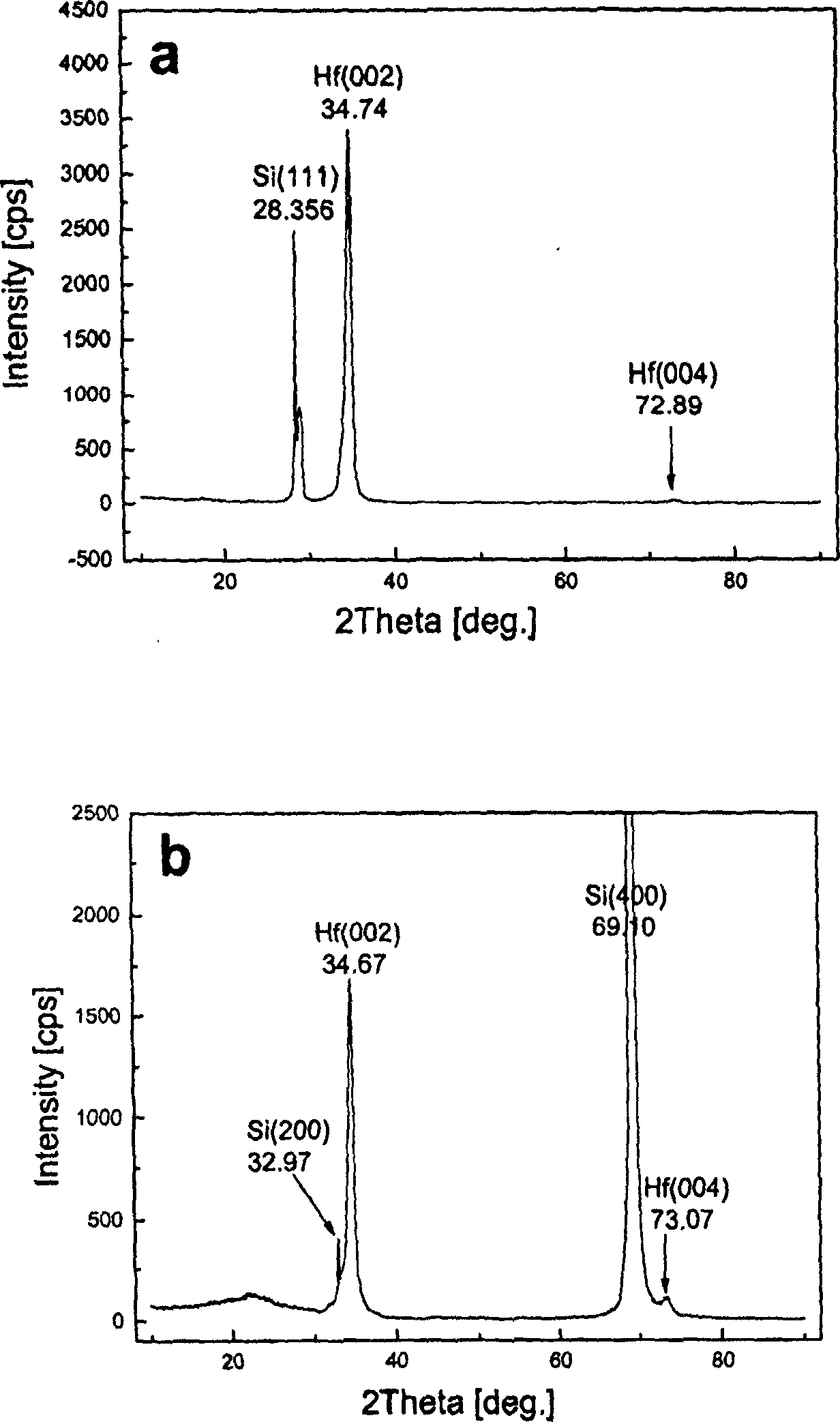

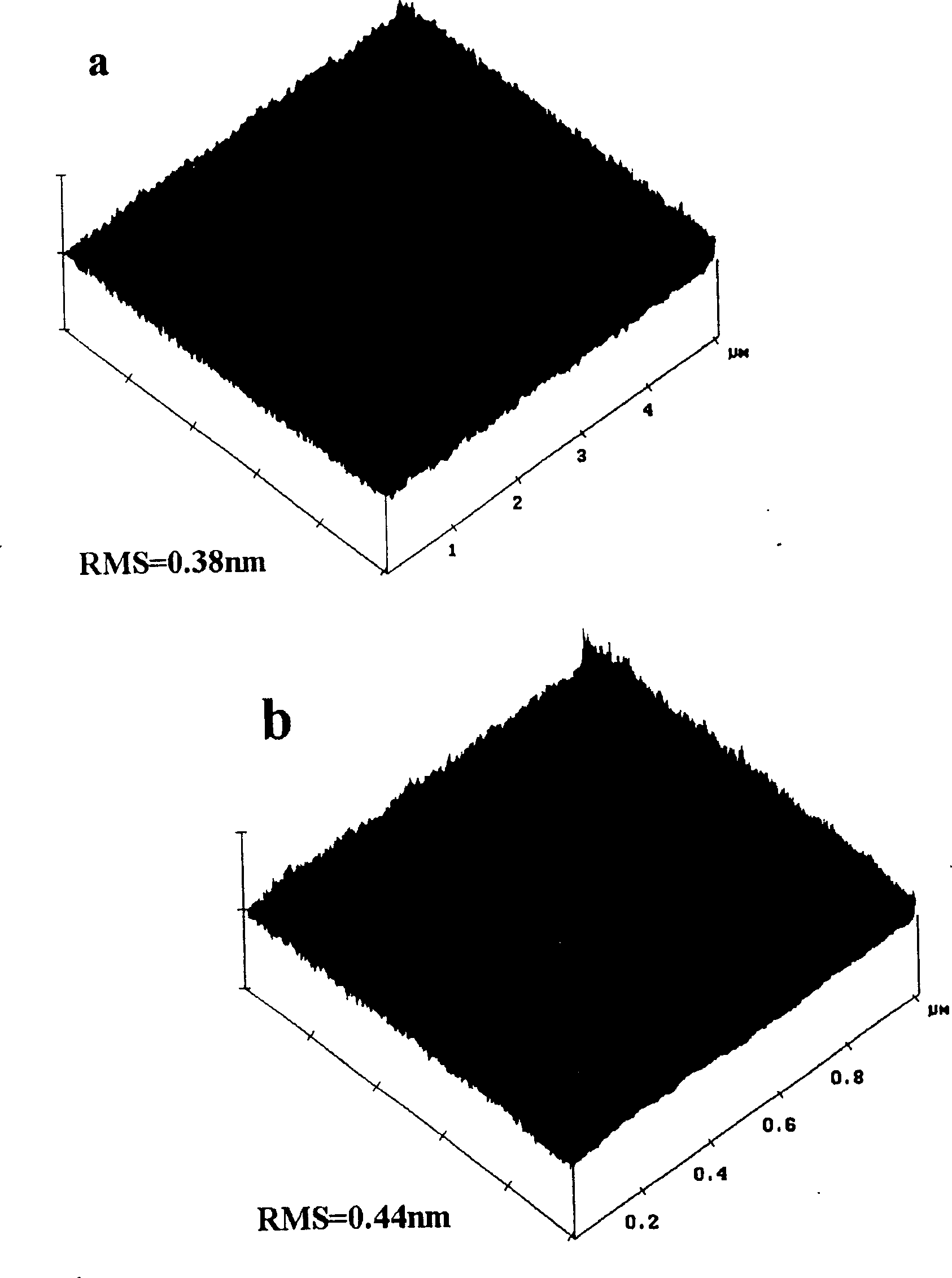

Examples

specific Embodiment

[0102] The best way to implement the present invention:

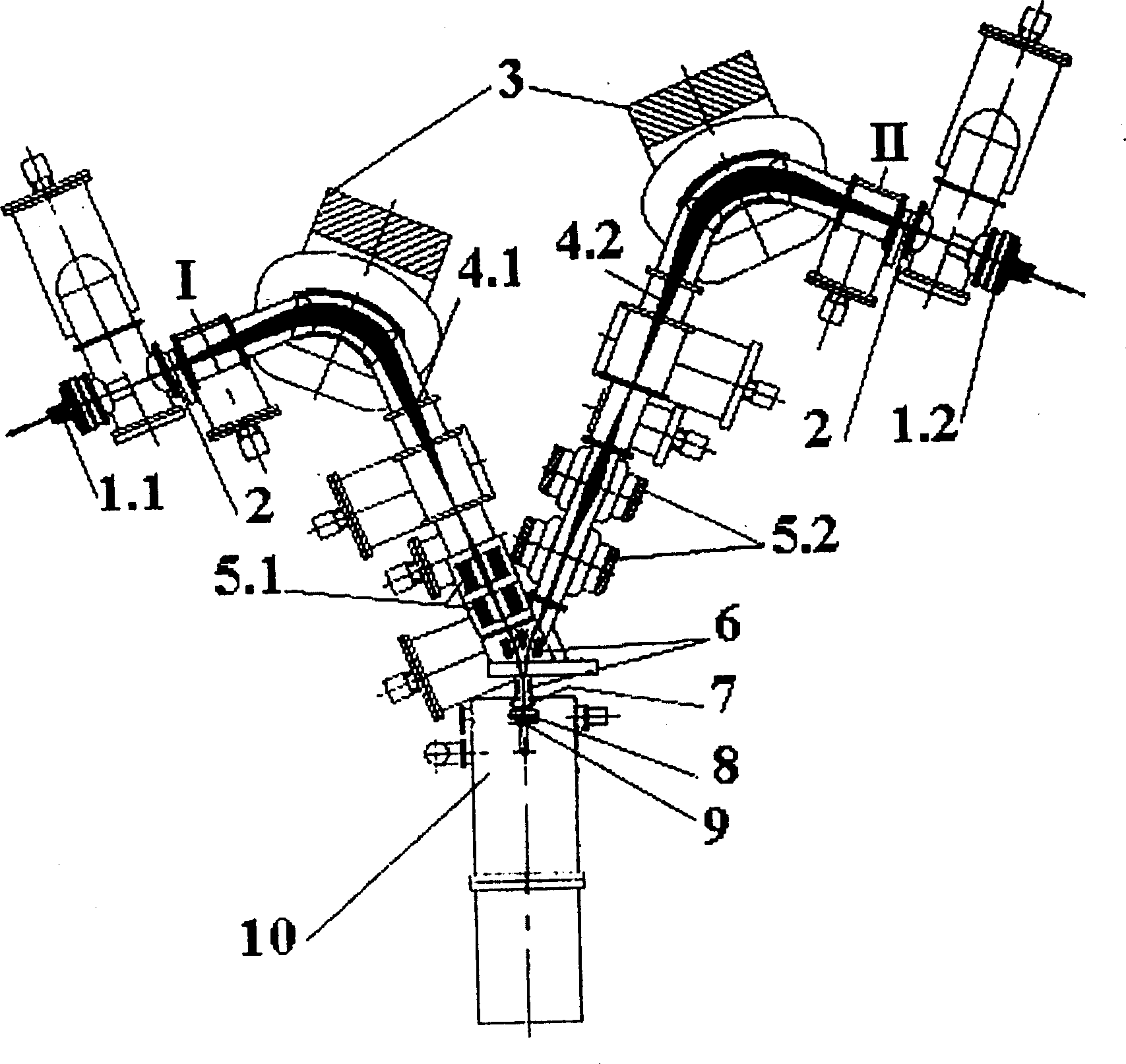

[0103] 1. Main equipment to realize the invention:

[0104] Ion beam epitaxial growth equipment, vacuum equipment (mechanical vacuum pumps, turbo molecular pumps, cryogenic pumps, ion pumps, etc.), semiconductor substrate material cleaning equipment, etc.;

[0105] 2. According to the specific conditions of the growth equipment and the requirements of the metal hafnium film to be prepared, the technical route for the implementation of the present invention is designed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com