Prolan enzyme bacterial and preparation process

A technology of pullulanase and producing bacteria, applied in the field of pullulanase producing bacteria and preparation, and can solve problems such as enzyme inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

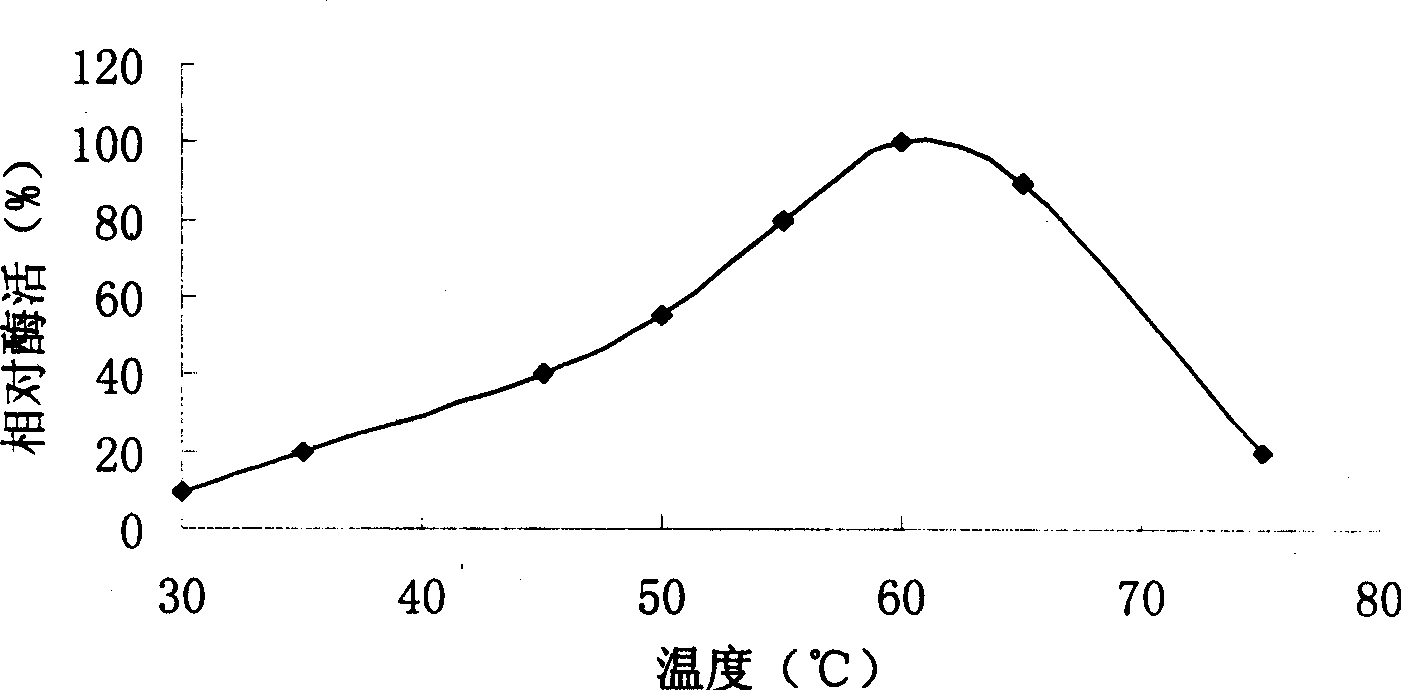

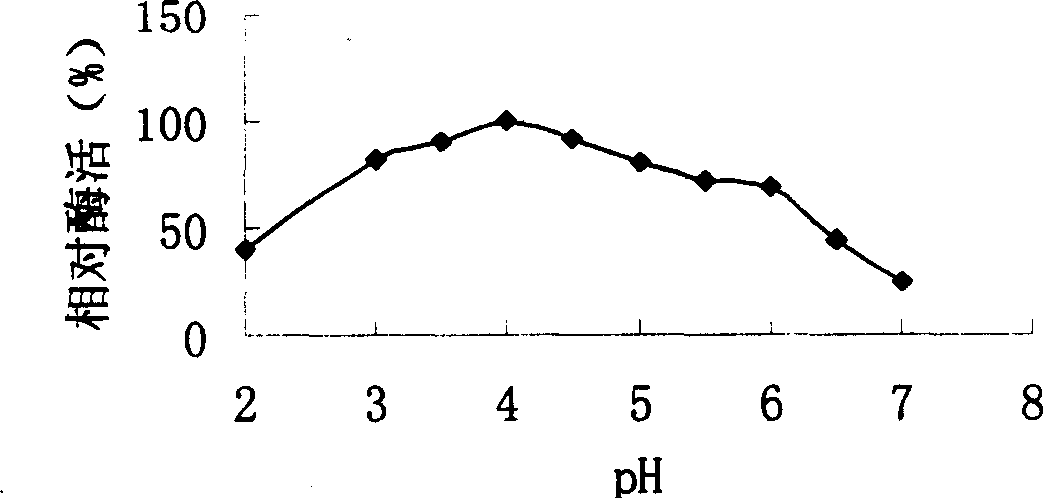

[0034] 1. Isolation of strains:

[0035] Water samples from Tengchong Hot Spring in Yunnan Province and soil samples around the hot spring were collected. During the experiment, 5g of the soil sample was weighed into 45ml of normal saline, and glass beads were added to fully shake and then allowed to stand for 1 hour. Take 100 μl of the supernatant of the soil sample in a test tube, do gradient dilution, take an appropriate dilution to smear on a plate, and incubate in an electric constant temperature incubator at 50°C for 48hrs. Drop an appropriate amount of iodine solution with a concentration of 1% on the separation plate, pick the strains with blue transparent circles, separate and purify by streaking, culture at 50°C for 24 hours, and then transfer the strains with blue transparent circles into the identification medium. After culturing in the incubator for 48 hours, select the strains that can produce white decomposition circles on the red pullulan plate and continue to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com