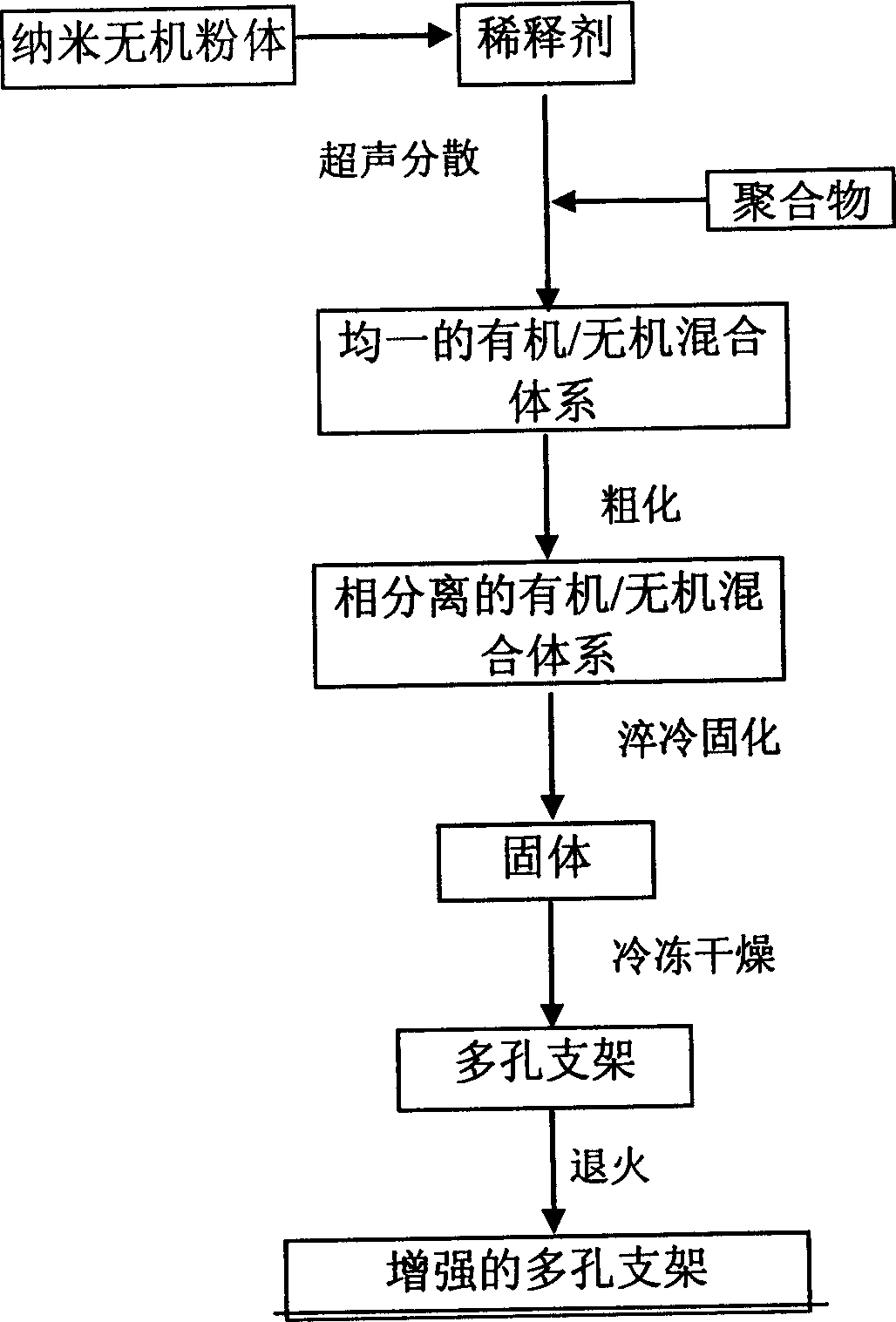

Method for preparing organic and inorganic nanometer composite organization engineering stent material by using thermal phase separation

A technology of thermally induced phase separation and inorganic nanotechnology, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve the problems of difficult control of material pore size, porosity and connectivity, and irregular seepage movement, etc. Achieve high strength and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1. Preparation of Organic / Inorganic Nanocomposite Tissue Engineering Scaffold Materials

[0035] Weighed 0.1 g of nano-hydroxyapatite and put it in 9 ml of 1,4-dioxane / deionized water (87 / 13) solution, and ultrasonically oscillated in the aqueous solution at 50° C. until uniformly dispersed. Add 0.9 g of poly-L-lactic acid (PLLA) to it while ultrasonically oscillating until the polymer is completely dissolved, and the nano-hydroxyapatite powder is evenly dispersed in the solution to form a uniform mixing system. The mixed system was lowered to 15° C. (9° C.) below the cloud point temperature of the mixed system and allowed to stand for 6 hours to allow phase separation to occur. The samples were quick-frozen at minus 50°C, and kept warm for 12 hours to fully solidify. The sample was placed in a freeze dryer and freeze-dried at minus 40°C for 36 hours to completely remove the diluent. The sample was placed in an oven, heated to 65° C., kept for 12 hours, and th...

Embodiment 2

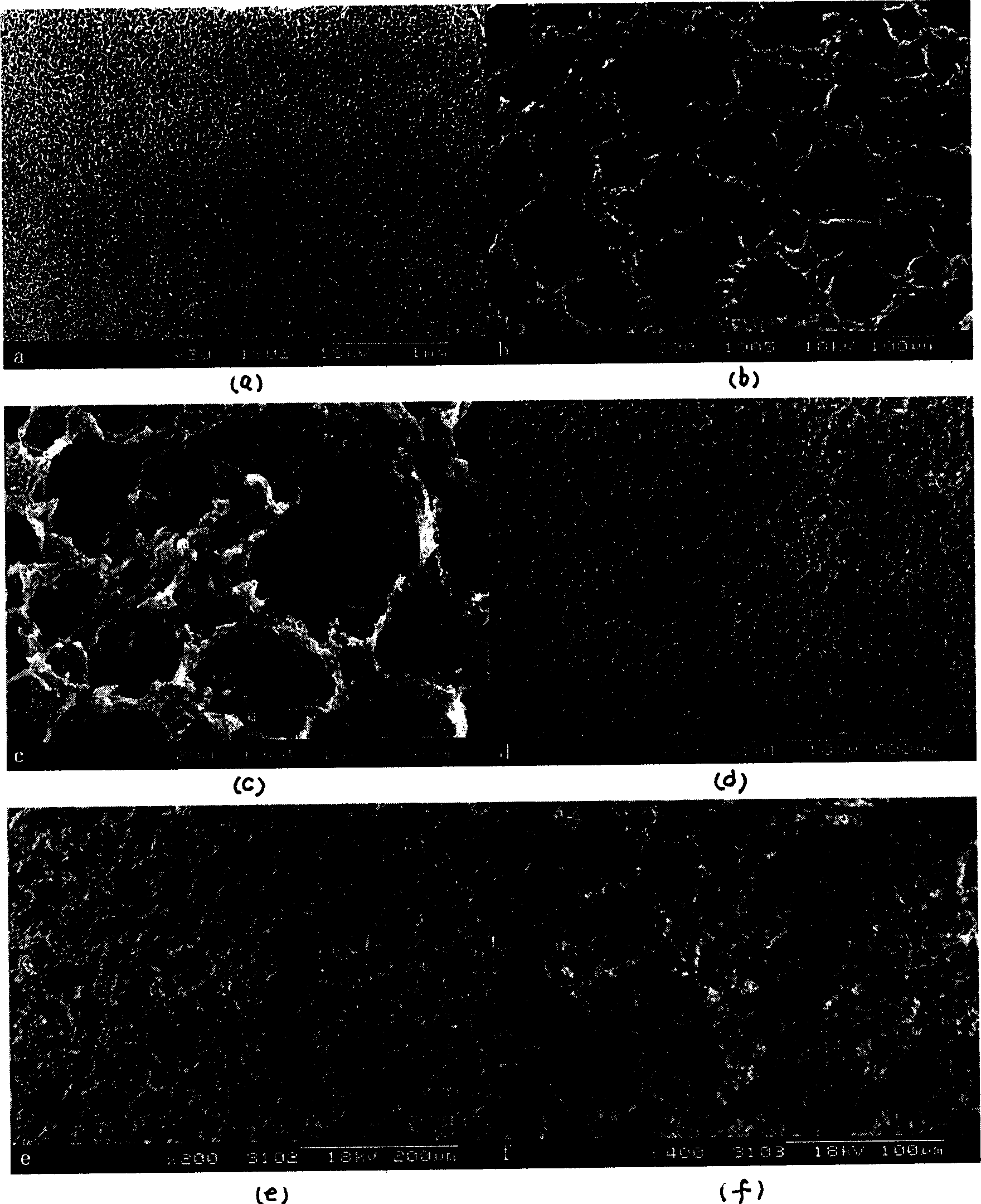

[0036] Example 2. Controlling the Structure and Properties of Porous Scaffold Materials by Polymer Concentration

[0037] Prepare nano-hydroxyapatite / lactic acid-glycolic acid copolymer (PLGA) porous scaffold according to the method in application example 1, change the copolymer PLGA concentration, obtain the 1 of different concentration HA / PLGA (HA: PLGA=5: 95), 4-dioxane / water (87 / 13) solution was coarsened at 5° C. for 6 hours to obtain the scaffold. image 3 (a), (b), (c) are the scanning electron micrographs of scaffold materials obtained under the polymer concentration of 8% (w / v), (d), (e), (f) are 10% (w / v) Scanning electron micrographs of scaffold materials obtained under polymer concentration. Depend on image 3 It can be seen that the pore size of the porous scaffold can be controlled by adjusting the polymer concentration. The porosity of the scaffold material can also be controlled by the polymer concentration, see Table 1.

Embodiment 3

[0038] Example 3. Controlling the Structure of Porous Scaffold Materials by Coarsening Temperature

[0039] Prepare nano-hydroxyapatite / copolymer of lactic acid-glycolic acid (PLGA) porous scaffold according to the method in application example 1, prepare porous scaffold under different roughening temperatures, obtain 10% (w / v) HA / PLGA (HA : PLGA=5:95) in dioxane / water (87 / 13) solutions roughened at different roughening temperatures for 6 hours to obtain scaffolds. Figure 4 (a), (e), and (c) are scanning electron micrographs of scaffold materials obtained at a roughening temperature of 9°C; (d), (b), and (f) are photos of scaffold materials obtained at a roughening temperature of 5°C SEM photo. Depend on Figure 4 It can be seen that the pore size of the porous scaffold can be controlled by adjusting the roughening temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com