Heating film manufacturing method and its relational heater

A manufacturing method and heating film technology, which are used in the manufacture of printed circuits, transparent/reflective heating devices, electrical components, etc., can solve the problems of reducing the service life of the heating film, heating film-induced flame, circuit line damage, etc., to solve the problem of low durability. , improve the service life, the effect of simple manufacturing engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

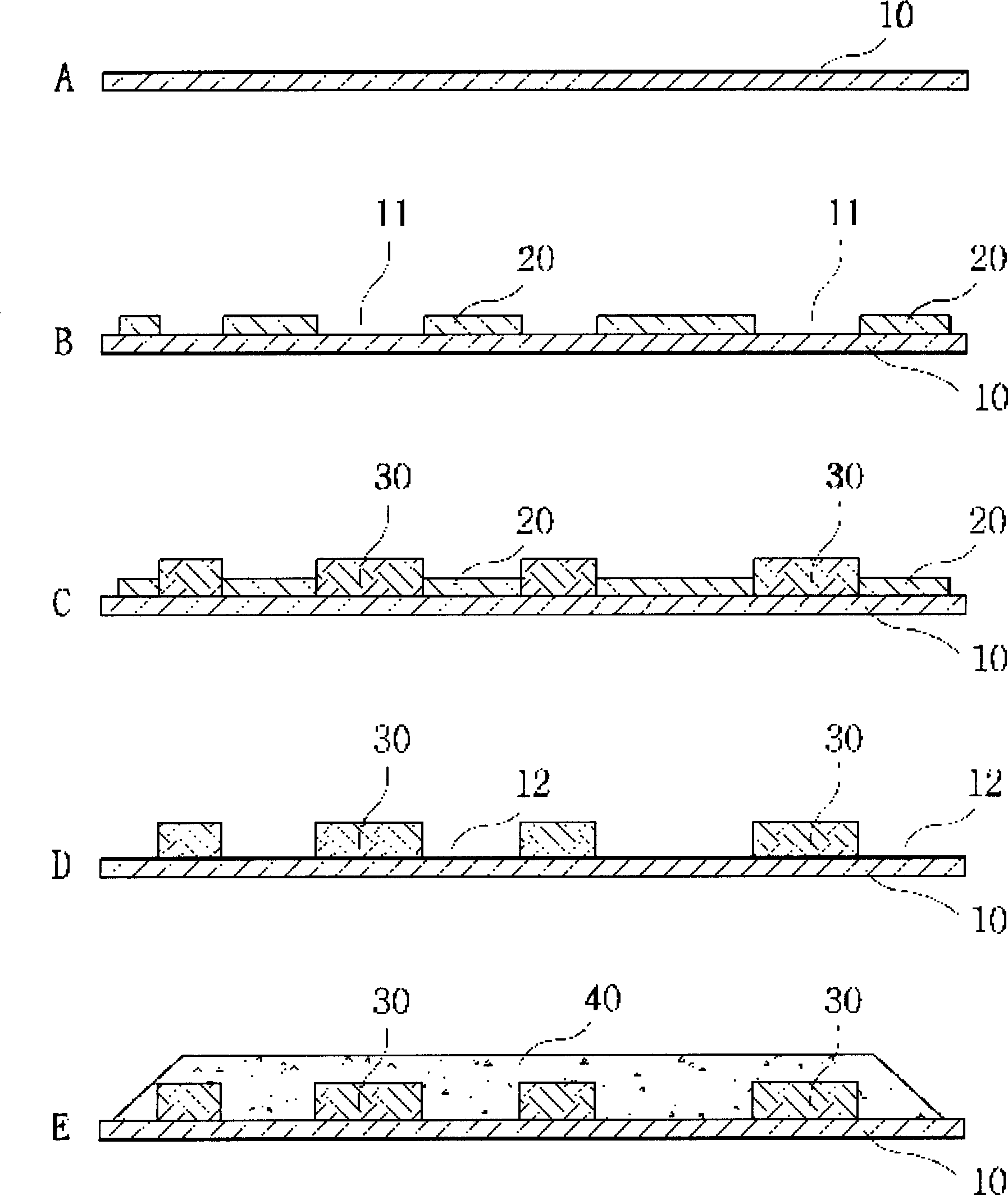

[0017] Embodiment 1: The manufacturing method of PTC type heating film is described in detail. Such as figure 1 As shown, at first determine the size of insulating layers (10) such as PET layers according to the required specifications, and form rolls after cutting. refer to figure 1 The PTC type heating film manufacturing method engineering drawing shown in figure 1 A, (reference figure 1 A).

[0018] Water-soluble Metallize Resist ink (resist ink treated with metal) is overprinted on the specified electrode layer on the surface of the insulating layer, and dried. (refer to figure 1 B). The water-soluble Metallize Resist ink (resistance ink processed with metal) used in the production process of the present invention is the kp-1000 product manufactured by Korea KTS Co., Ltd.

[0019] After the circuit line (20) is printed on the insulating layer (10), the part (11) of the non-printed circuit line (20) on the surface of the insulating layer is selected from copper, silv...

Embodiment 2

[0023] Embodiment 2: The manufacturing method of the PTC type heating film is described in detail. First, if figure 1 After the insulating layer (10) shown in A is prepared, as figure 1 As shown in B, on the electrode layer specified on the surface of the insulating layer (10), cover the surface of the insulating layer (10) with a protective mold (shown at the end of the figure) to form a specified circuit line (20), and use a protective mold instead of using a water-soluble Metallize Resist ink (resistive ink processed with metal) forms circuit lines (20) on the insulating layer (10).

[0024] After the circuit line (20) on the insulating layer (10) is formed, on the part (11) of the surface of the insulating layer (10) that does not cover the protective mold, use copper, silver, and gold to choose one of gold plating or vacuum coating to form a specified electrode layer (30) (reference figure 1 C), the circuit line (20) can be designed and manufactured according to needs,...

Embodiment 3

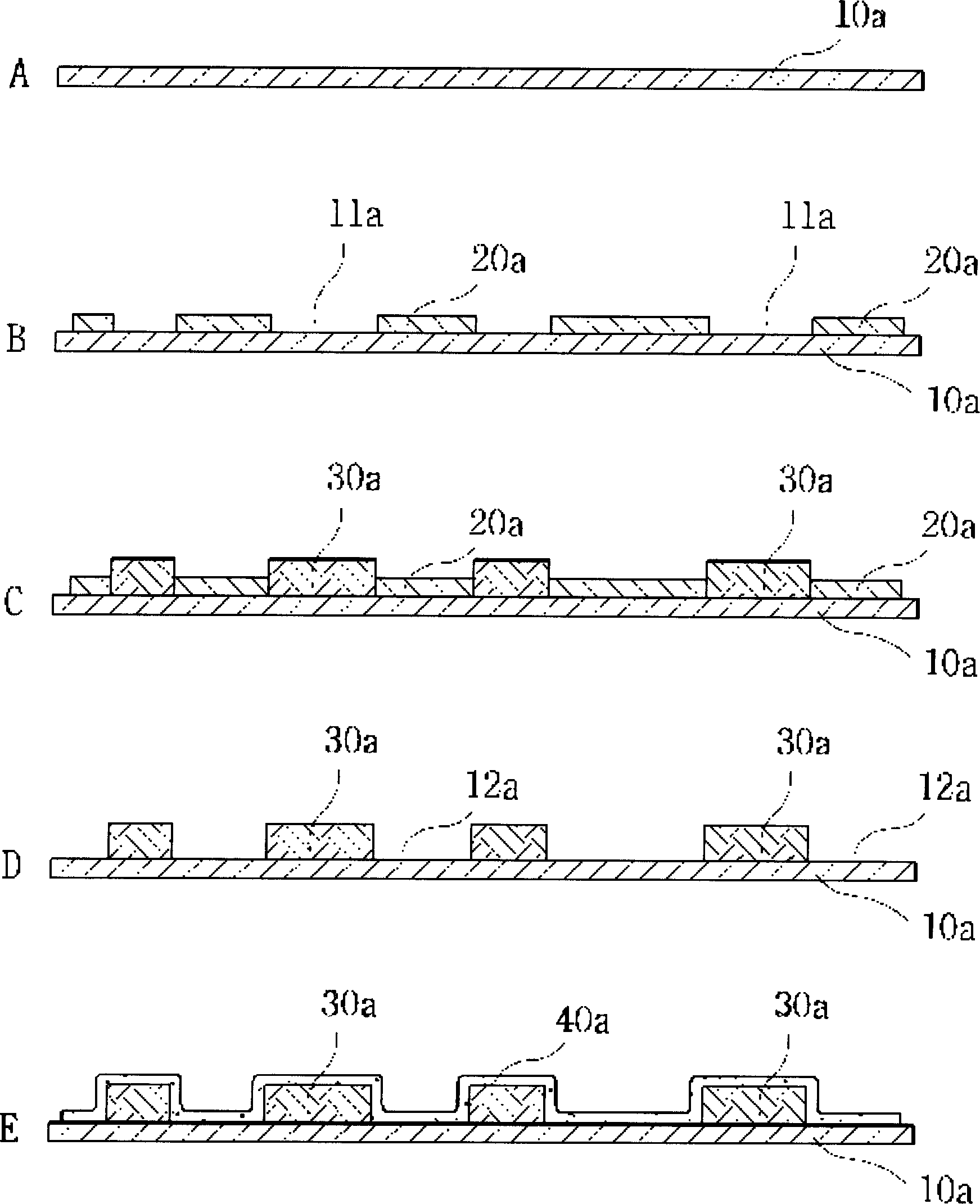

[0029] Embodiment 3: The manufacturing method of the NON-PTC type heating film is described in detail. image 3 It is an engineering drawing of the NON-PTC type heating film manufacturing method. First determine the size and shape of insulating layers (10a) such as PET layers according to the required specifications and cut them into rolls. (refer to image 3 A)

[0030] After the above insulating layer (10a) is prepared, the prescribed circuit lines (20a) are covered and printed on the insulating layer with water-soluble Metallize Resist ink (resist ink treated with metal), and dried. (refer to image 3 B) The water-soluble Metallize Resist ink (resistive ink treated with metal) used is a KP-1000 product manufactured by Korea KTS Co., Ltd.

[0031] After the circuit line (20a) is printed on the insulating layer (10a), choose one of copper, silver, and gold, and on the uncovered part (11a) above the insulating layer (10a), gold plating or vacuum plating forms a specified Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com