Preparation method for high-performance cement

A high-performance cement technology, applied in the field of high-performance cement preparation, can solve the problem of low durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

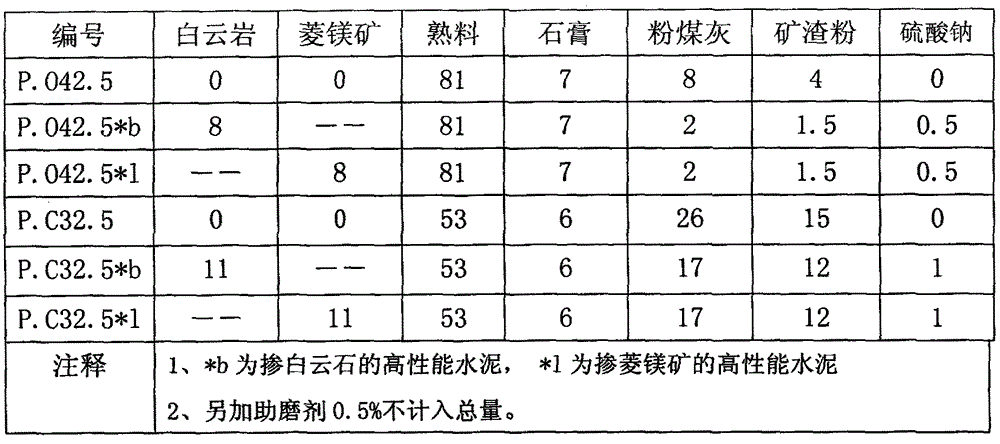

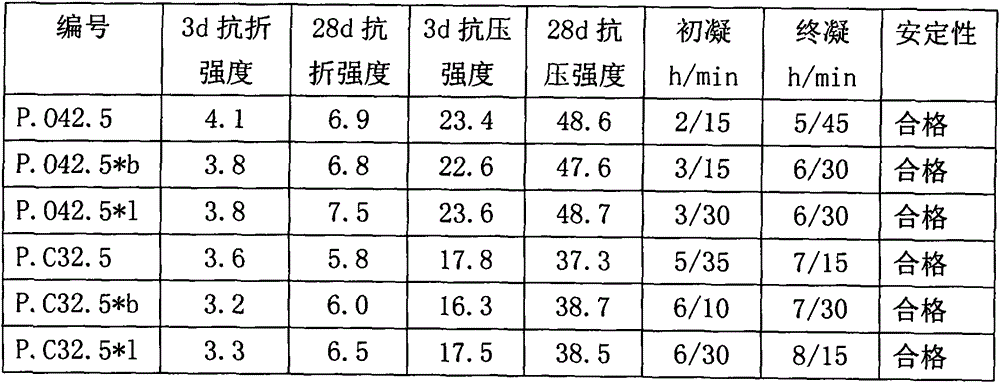

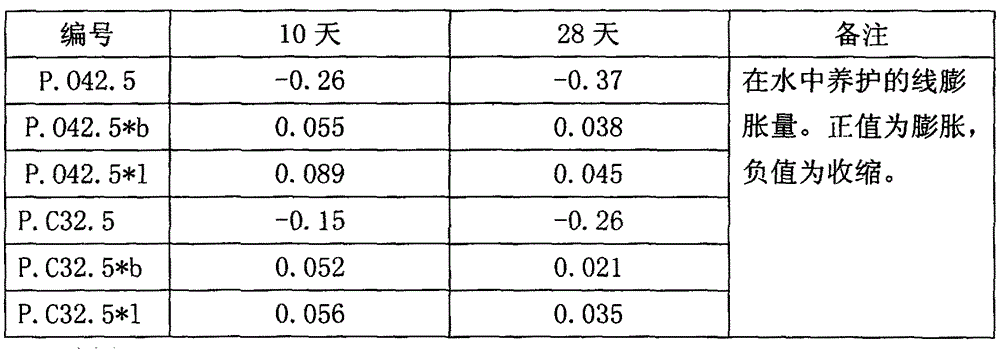

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 Contrast test of impervious concrete:

[0037] C30P6 pumping impervious concrete foundation (blank) mix ratio: general-purpose Portland Portland PO42.5 strength grade cement, cement dosage 325kg, medium sand 835kg, crushed stone 5-31.5mm particle size 1010kg, water 170kg, naphthalene water reducing Dosage 9kg. In 28 days, the actual test impermeability level reached the P8 requirement.

[0038] C30P6 pumping impervious concrete test proportion: P.O42.5*b high-performance cement 325kg, sand 835kg, gravel 5-31.5mm particle size 1010kg, water 170kg, naphthalene-based water reducing agent 9kg. In 28 days, the actual impermeability grade reaches the requirements of P14.

[0039] C30P6 pumping impervious concrete test proportion: P.O42.5*1 high-performance cement 325kg, sand 835kg, gravel 5-31.5mm particle size 1010kg, water 170kg, naphthalene-based water reducing agent 9kg. In 28 days, the actual impermeability level reaches the requirements of P18.

Embodiment 2

[0040] Embodiment 2 Freeze-resistant concrete comparative test:

[0041] C30F100 pumping antifreeze concrete foundation (blank) mix ratio: general-purpose Portland Portland PO42.5 strength grade cement, cement dosage is 325kg, medium sand is 835kg, crushed stone particle size is (5mm~31.5mm) 1010kg, water 160kg, naphthalene It is 9.5kg of water reducer. A 100×100×100mm cubic concrete specimen was made, and after 28 days of standard curing, the actual test of the concrete specimen’s resistance to freezing and thawing was up to 100 times qualified.

[0042] C30F100 pumping antifreeze concrete test mix ratio: P.O42.5*b high-performance cement, cement dosage 325kg, sand 835kg, crushed stone particle size (5mm~31.5mm) 1010kg, water 160kg, naphthalene-based water reducing agent 9.5kg . After 28 days of standard curing, the actual detection of concrete resistance to freezing and thawing reaches 150 times. qualified

[0043] C30F100 pumping antifreeze concrete test mix ratio: P.O4...

Embodiment 3

[0044] Embodiment 3 anti-carbonation concrete:

[0045] C20 concrete benchmark (blank) ratio: PC32.5 general-purpose Portland cement, cement alkali content 1.2%, cement dosage 302kg, gravel (5-31.5mm) 1238kg, sand 625kg water 175kg, naphthalene-based water reducer 9.1 kg. After 28 days, the average carbonization depth was actually detected by the standard carbonization box carbonization experiment to be 9.3mm.

[0046] C20 concrete test ratio: P.C32.5*b high-performance cement, cement dosage 302kg, sand 625kg, gravel (5-31.5mm) 1238kg, water 175kg, naphthalene-based water reducing agent 9.1kg. After 28 days, the average carbonization depth was actually detected by the standard carbonization box carbonization experiment to be 5.4mm.

[0047] C20 concrete test ratio: P.O32.5*1 high-performance cement, cement dosage 302kg, sand 625kg, gravel (5-31.5mm) 1238kg, water 175kg, naphthalene-based water reducing agent 9.1kg. After 28 days, the average carbonization depth was actually...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com