Internal combustion circulating energy conversion system for supercritical oxidation

A technology of supercritical oxidation and cycle energy, which is applied in the direction of combustion equipment, solid fuel combustion, lighting and heating equipment, etc., and can solve the problems of collection and processing without further explanation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

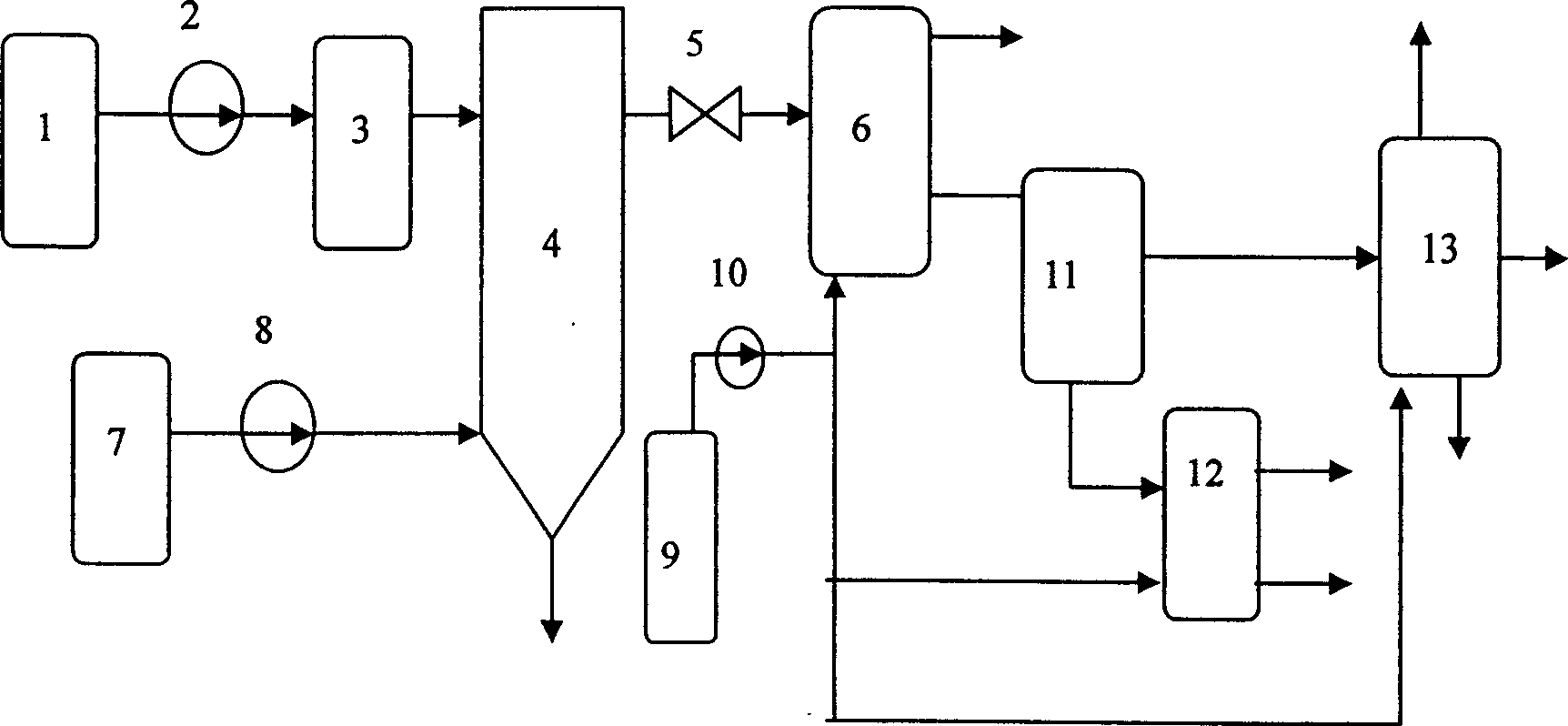

[0023] Firstly, water and coal powder are mixed in the fuel mixer (1) and ground into a slurry, and the mixture is boosted by a high-pressure metering pump (2) and pushed into the preheater (3) for preheating, and then enters the supercritical reactor (4); Oxygen is pressurized from the oxygen tank (7) by the gas booster pump (8), and enters the inside of the supercritical reactor (4) equally. Under supercritical conditions, that is, 25MPa and above 400°C, fuel reacts with oxygen to generate supercritical water, gas products and solid mixtures. Through gas-solid separation, the solid is discharged from the system, and the gas enters the primary heat exchanger (6) for heat exchange. Water and CO are realized at 7 to 22MPa and 30 to 350°C in the primary gas-liquid separator (11). 2 Wait for the separation of other gases, and discharge the condensed water. The remaining gas is continued to be cooled through the secondary heat exchanger (12), and the CO 2 Separation and recover...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that the condensed water is discharged, the organic waste water is input as circulating water, and the heat of the organic matter in the waste water is recovered, and the waste water is purified to solve the waste water pollution problem. All the other processes are the same as in Example 1.

Embodiment 3

[0027] The difference between this embodiment and embodiment 1 is that the fuel is replaced with straw, and the rest of the process is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com