Preparation method of azodiisobutyronitrile

A technology for the reaction of azobisisobutyronitrile, which is applied in the field of preparation of organic compound azobisisobutyronitrile, can solve the problems of low yield and no condensation waste water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

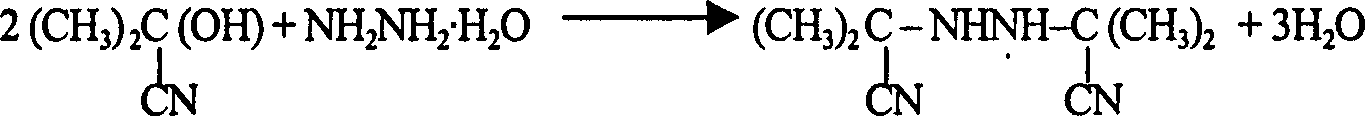

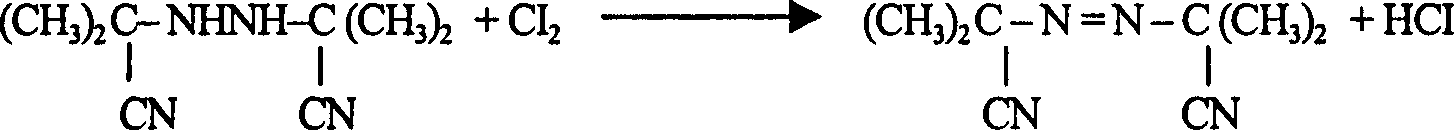

Image

Examples

Embodiment 1

[0020] The preparation of embodiment 1 azobisisobutyronitrile

[0021] Preparation of diisobutyronitrile hydrazine: add 100g (1.153mol) of 98% acetone cyanohydrin and 150g (8.3mol) of condensation waste water in a 500ml three-necked flask, and control the pH value of condensation waste water at 4.8. Carry out condensation reaction, control reaction temperature between 51~60 ℃, reaction time is 3 hours. Then the feed solution was cooled to 10°C, crystallized, and filtered to obtain diisobutyronitrile hydrazine.

[0022] respectively in 1 # ,2 # Add the obtained diisobutyronitrile hydrazine into a 1000ml three-neck flask to dilute with water, the amount of water added is 400ml, and the mixed solution is cooled to 10°C, and then oxidized by passing chlorine gas. 1 # The residual chlorine produced during the chlorine oxidation process in the bottle is within 2 # Absorb in the bottle, control the chlorine flow rate during the chlorine flow process to 0.025-0.030mol / min, 2 # T...

Embodiment 2

[0027] Embodiment 2 Preparation of azobisisobutyronitrile

[0028] Preparation of diisobutyronitrile hydrazine: add 200g (2.306mol) of 98% acetone cyanohydrin and 380g (21.1mol) of condensation waste water in a 1000ml three-necked flask, and control the pH value of condensation waste water at 4.4. For the condensation reaction, the reaction temperature is controlled to be stable between 51°C and 60°C, and the reaction time is 3.5 hours. Then the reaction solution was cooled to 10°C, crystallized, and filtered to obtain diisobutyronitrile hydrazine.

[0029] respectively in 1 # ,2 # Add the obtained diisobutyronitrile hydrazine into a 2000ml three-neck flask to dilute with water, the amount of water added is 850ml, and the mixed solution is cooled to 8°C, and then oxidized by passing chlorine gas. 1 # The residual chlorine generated during the chlorine oxidation process in the bottle is within 2 # Absorb in the bottle, control the speed of chlorine flow at 0.021 ~ 0.025mol...

Embodiment 3

[0031] Embodiment 3 control experiment

[0032] 100g (1.153mol) of 98% acetone cyanohydrin and 270g (15mol) of condensation wastewater controlled at a pH of 6.5 were added into a 500ml three-necked flask to react with 36.5g (0.584mol) of 80% hydrazine hydrate. The condensation reaction temperature is controlled to be between 50-60° C., and the reaction time is controlled to be 3.5 hours. Then the feed solution was cooled to 10°C, crystallized, and filtered to obtain diisobutyronitrile hydrazine. The obtained diisobutyronitrile hydrazine was diluted with water, the amount of water added was 400ml, and the mixture was cooled to 10°C. Then carry out the oxidation reaction in a single oxidation device with chlorine gas, and use 10% sodium hypobromite solution titration to control the oxidation reaction end point according to the routine operation. It is the end point that no white precipitate occurs in the titration, and consumes 40g of chlorine gas to obtain azobisisobutyl The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com