Electronic transformer/inductor devices and methods for making same

A technology for inductors and transformers, applied in the field of electronic transformers/inductor devices and their manufacturing, can solve the problem of heat being not easily dissipated, and achieve the effects of excellent repeatability, simplified electrical connection, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

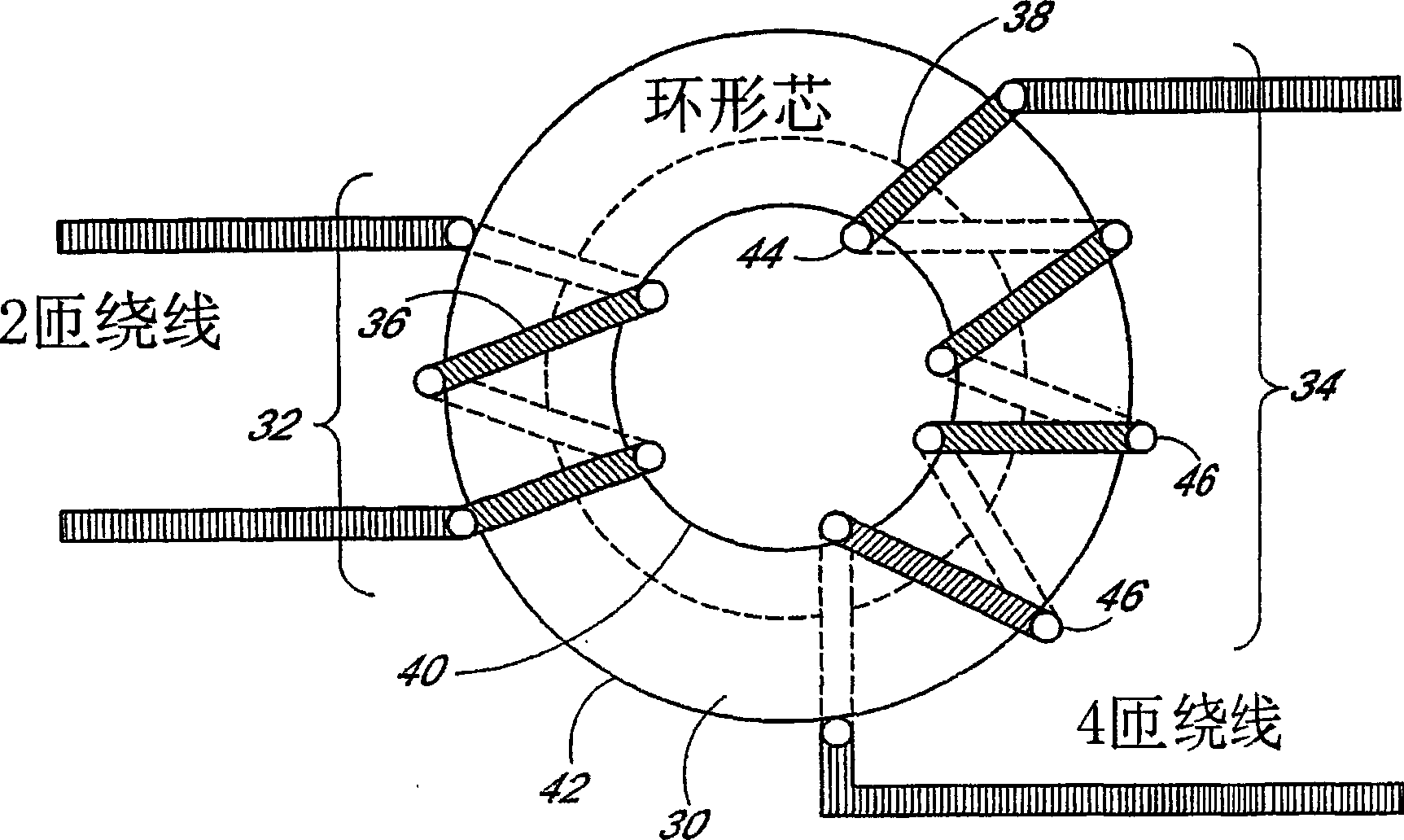

Image

Examples

Embodiment

[0053] Many inductive devices such as low frequency power transformers require a magnetic core with a relatively high relative permeability, typically in the range of 10,000-100,000. However, improvements provided by the preferred embodiment are available for lower and higher values, for example in the range of 1000-1000000. Certain metals and metal alloys provide these high flux densities, including steel, iron, silica Iron, permalloy 78, Mumetal, refined iron, and supermalloy ). While these high flux densities can provide significant advantages in constructing transformers and inductors, the low resistivity of metals allows induced eddy current flow, which negates the advantages of higher flux densities. The induced eddy currents 300 generated by the magnetic flux flowing in the metal core are shown in Figure 13 middle. These eddy currents are reduced in current metal cored transformers / inductors by forming a toroidal or E-shaped core out of laminated metal E-strips, wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com