Battery

A battery and positive electrode technology, applied in the field of flat primary batteries, can solve the problems of button-type battery load characteristics and discharge capacity insufficiency, inter-battery capacity changes, gas and internal short circuits, etc., to prevent sudden deterioration and prevent capacity. The effect of reducing and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

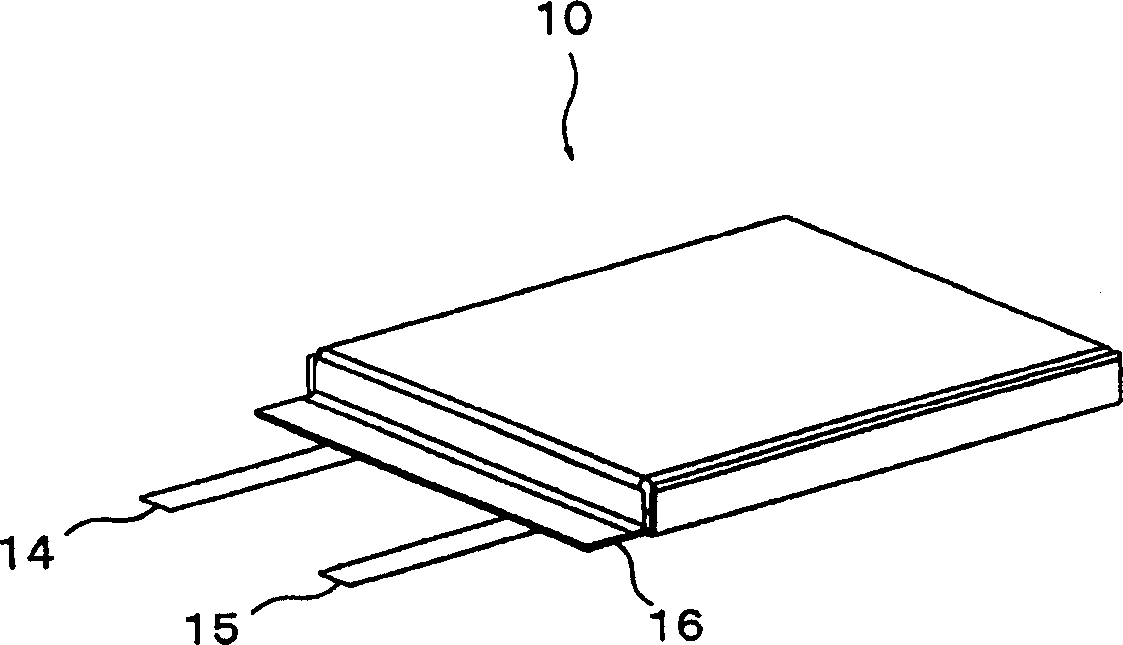

Image

Examples

Embodiment 1

[0109] 80.8 mass percent of graphite fluoride as a positive electrode active material and 15.1 mass percent of acetylene black as a conductive material were uniformly mixed and dispersed in ethanol, thereby obtaining a slurry. After that, acetylene black as a binder was mixed in a ratio of 4.1% by mass. In this case, carboxymethylcellulose dissolved in water was mixed as a thickener and the viscosity was adjusted to a predetermined value (200 Pas), thereby obtaining a positive electrode mixture.

[0110] An aluminum foil with 20 μm was used as the positive electrode collector. The positive electrode active material layer was formed by screen printing the positive electrode mixture onto an aluminum foil. The positive electrode formed as described above was dried in a vacuum environment, and thereafter the positive electrode was bent as Figure 12 The W shape shown. Set up the microporous membrane as the separator, thereafter, as in Figure 12 Metal lithium is provided, ther...

example 1-1

[0114] A battery was formed in which the width was equal to 28 mm, the length was equal to 49 mm, the thickness was equal to 1.8 mm and the capacity was equal to 600 mAh.

example 1-2

[0116] A battery was formed in which the width was equal to 15 mm, the length was equal to 60 mm, the thickness was equal to 2.1 mm and the capacity was equal to 400 mAh.

[0117] A button-type battery in the related art was used as a comparative example. The following batteries were used as comparative examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com