Permanent-magnet dimagnetic combined suspension rotor micro gyroscope

A suspension rotor and magnetic combination technology, applied in the direction of rotating gyroscope, etc., can solve the problems of poor suspension and rotation stability, mutual interference between suspension and rotation, and unfavorable gyro function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

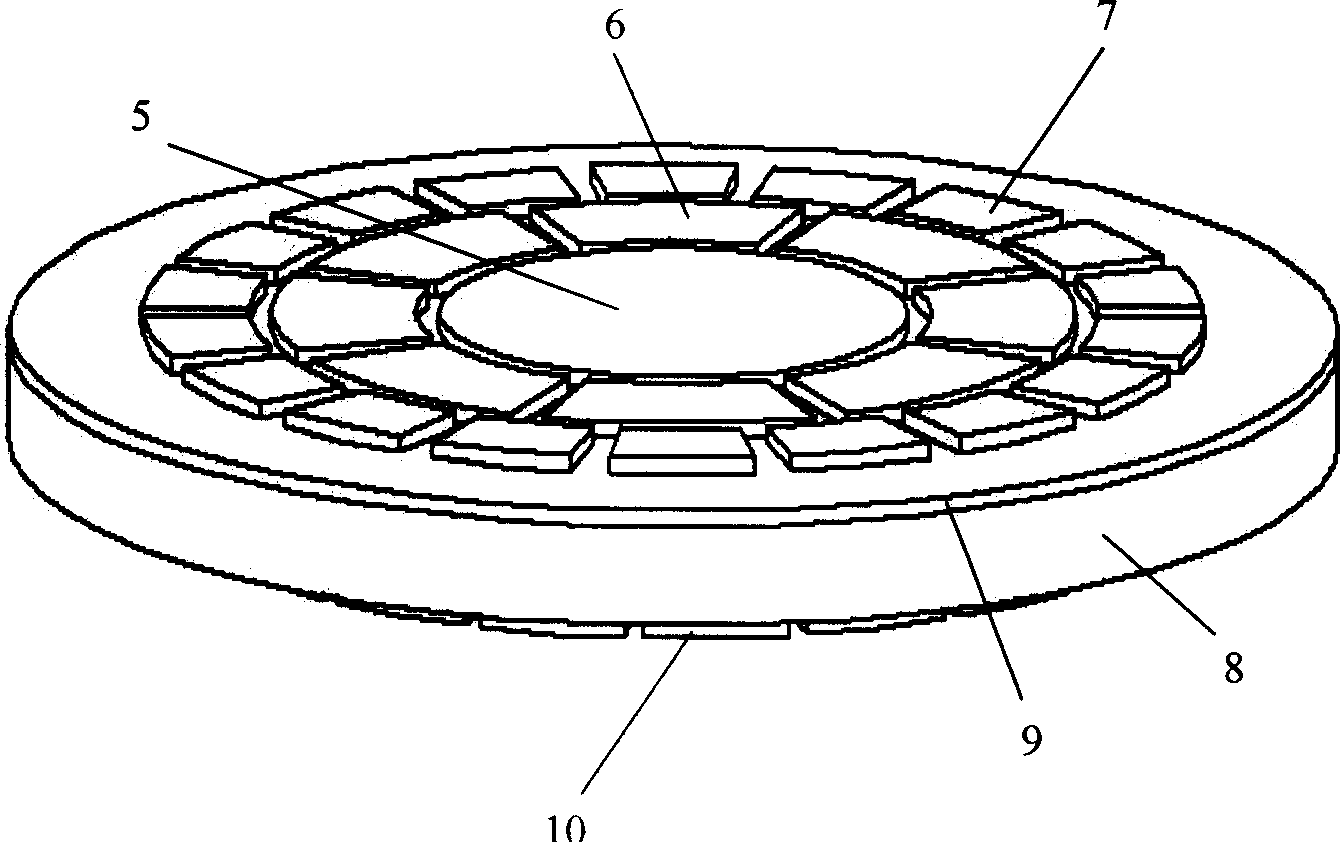

[0025] Such as figure 1 As shown, the present invention includes: an upper stator 1 , a lower stator 3 , a support ring 2 and a rotor 4 . The connection mode is that the upper stator 1, the lower stator 3 and the support ring 2 form a cavity, and the rotor 4 is located in this cavity.

[0026] Such as Figure 2-3 As shown, the upper stator 1 is provided with a dielectric material layer 8, an insulating support layer 9 is provided on the upper surface of the dielectric material layer 8, and a common electrode 5 is provided at the center of the outer surface of the insulating support layer 9, and then the insulating support is provided from the inside to the outside. The outer surface of the layer 9 is provided with 8 sector-shaped detection moment electrodes 6 uniformly arranged in the circumferential direction, and 18 sector-shaped rotating electrodes 7 uniformly arranged in the circumferential direction, and a permanent magnetic material layer 10 is provided on the lower sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com