Plate and column connecting method for steel structure building

A steel structure and construction technology, applied in the direction of construction, building structure, etc., can solve the problems of not finding the connection method between steel columns and stiffening plates, weakening the bearing capacity of components, and poor corrosion resistance, so as to reduce the intermediate force transmission link , Increase stability, clear force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

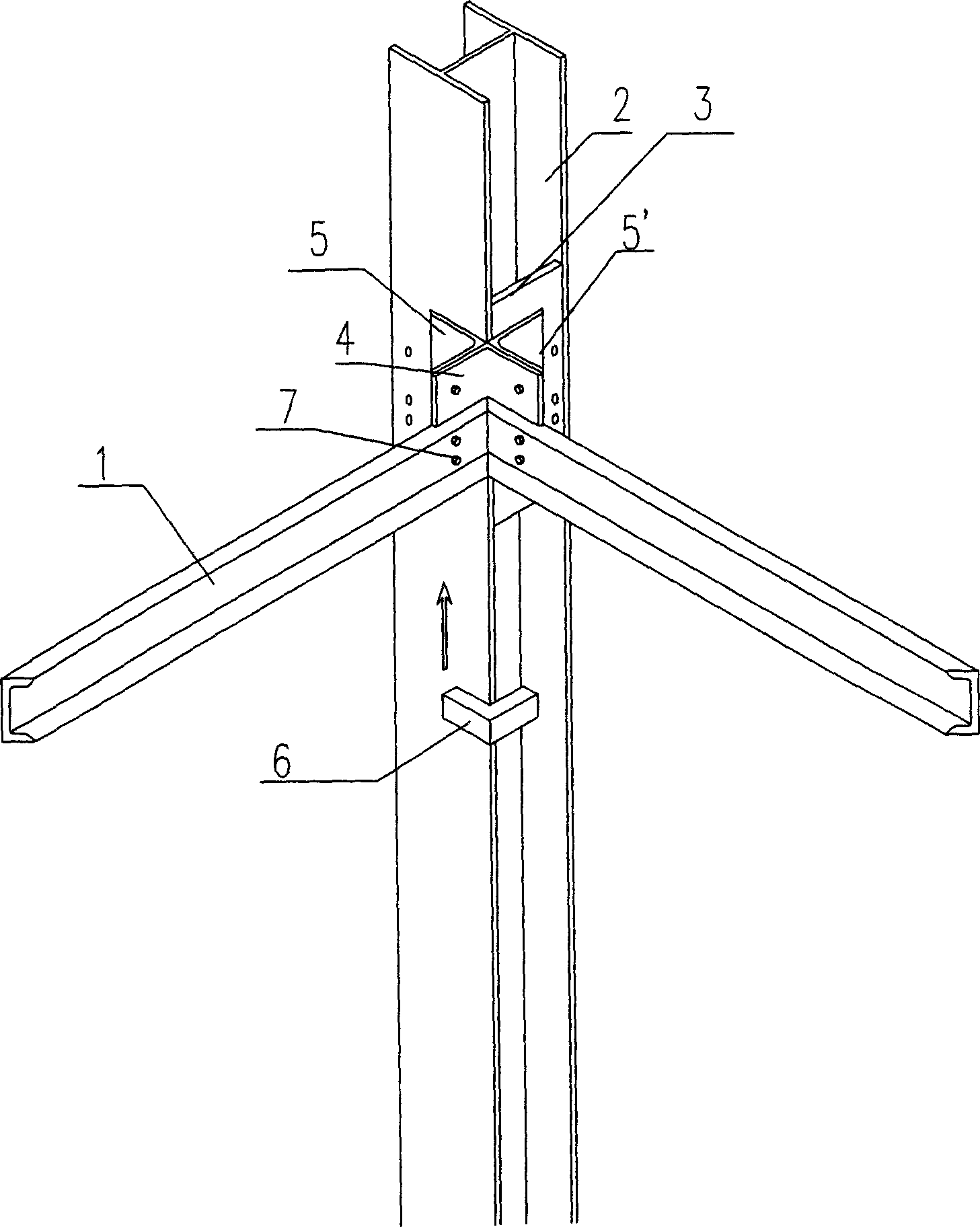

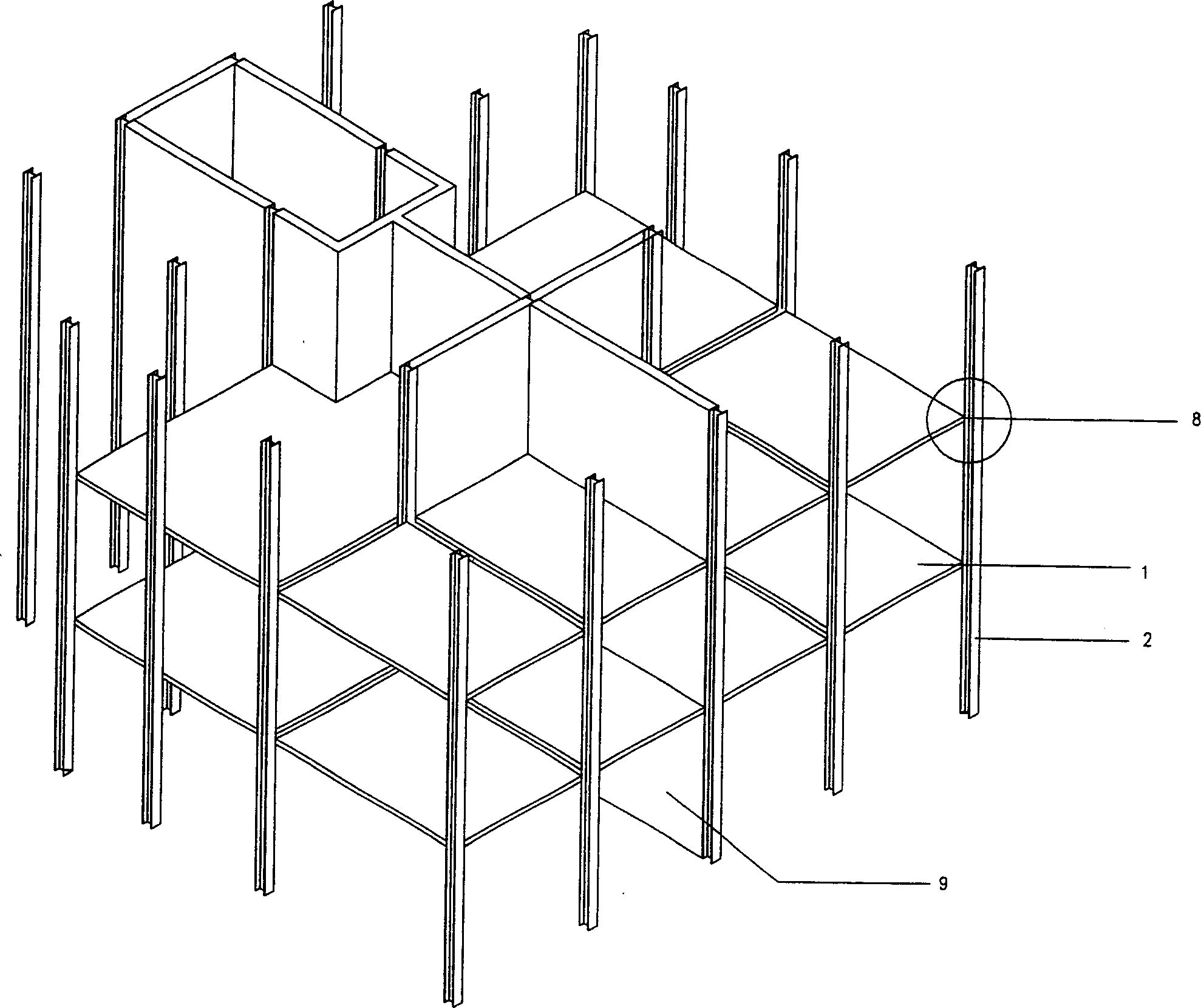

[0020] figure 1 It is the connection node diagram of column and plate, column 2 is H-shaped steel, and plate 1 is a box welded by channel steel. The column 2 and the plate 1 are connected by a connecting plate 5 . Connecting plate 5 is angle steel, also can be other forms. There are bolt holes on the two straight sides of the connecting plate 5, which are respectively connected with the corresponding bolt holes on the column 2 and the plate 1 through bolts 7. In order to ensure the strength, the bolt 7 is preferably a high-strength bolt, or a refined bolt that meets the strength requirement. An angle steel 4 is fixed on the corner of the plate 1, and there are bolt holes on the angle steel 4, which can be connected with the connecting plate 6. The present invention uses three bolts 7 to connect the column 2 and the connecting plate 5, and connects the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com