Method for treating adhesive before coating and aluminium alloy part

A technology for adhesives and metal parts, applied in the field of aluminum alloy parts, can solve problems such as difficult to conform, extremely high bonding strength and bonding durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

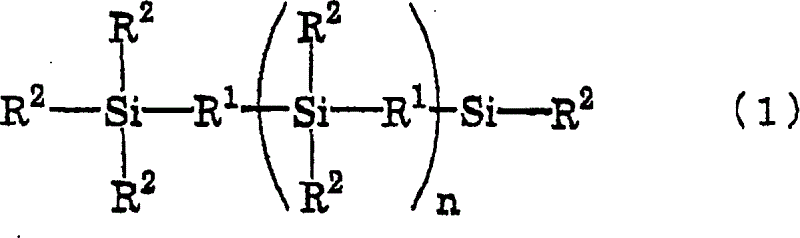

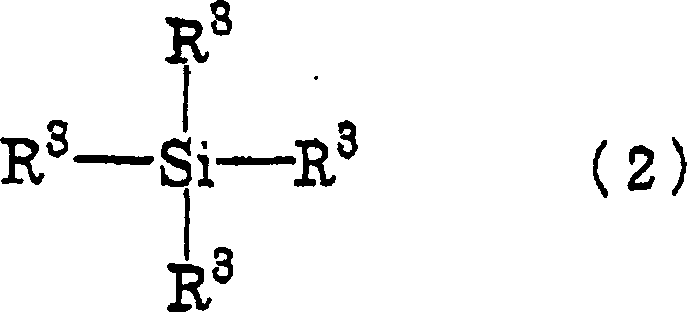

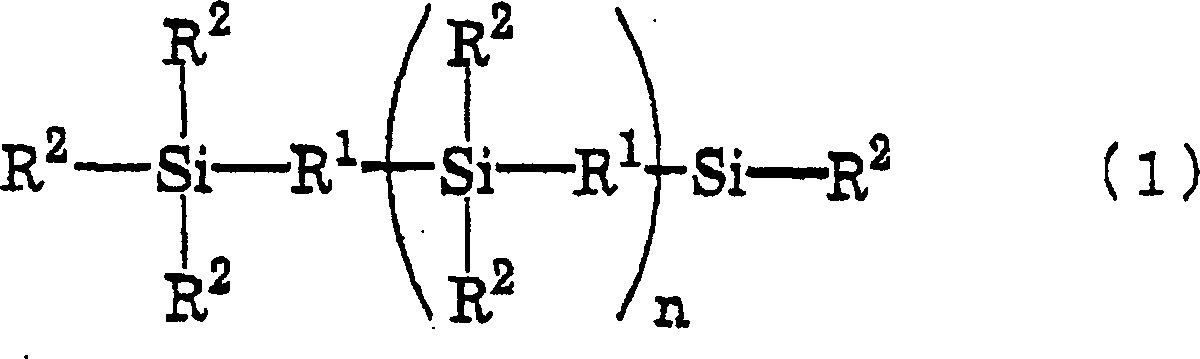

Method used

Image

Examples

manufacture example 1

[0057] Production Example 1 Preparation of Surface Treatment Liquid

[0058]Add 23.7gBTSE (1,2-bis(trimethoxysilyl)ethane) to the mixed solution of 9.7g ethanol, 0.075g acetic acid and 36.61g deionized water, and stir at room temperature for 3 days to obtain a transparent solution ( a). Next, 11.63gAPS (3-aminopropyltriethoxysilane: KBE-903 manufactured by Shin-Etsu Chemical Co., Ltd.) was added to a mixed solution of 165.2g deionized water and 2.95g acetic acid, and stirred at room temperature for 2 hours to obtain a solution ( b). The above solution (a) and solution (b) were mixed and stirred for 1 hour to obtain a surface treatment solution.

Embodiment 1

[0060] A brake shoe (aluminum die-casting) manufactured by Nippon Brake Co., Ltd. was used as the object to be processed. Using a 2% by mass solution of SURFCLEANER 53 (a degreasing agent manufactured by Nippon Paint Co., Ltd.), the brake shoe was dipped at 50° C. for 2 minutes. After washing with tap water, use H containing 200 ppm Zr 2 ZrF 6 , pH of 4.0 chemical treatment solution, immersion treatment for 2 minutes. After washing with tap water, immersion treatment was performed four times for 30 seconds each using a 20% by mass solution of the surface treatment liquid obtained in Production Example 1 whose pH was adjusted to 6. The obtained brake shoe was dried at 160° C. for 5 minutes. Zr and Si contained in the film obtained from the surface treatment liquid were respectively measured using a fluorescent X-ray apparatus (manufactured by Rigaku). The results are shown in Table 1.

[0061] The two pre-treated brake shoes and the friction lining A and friction lining B ...

Embodiment 2 and 3

[0064] Except for changing the number of immersion treatments with the surface treatment liquid shown in Table 1, brake shoes were prepared in the same manner as in Example 1, and evaluated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com