Solid polymer electrolyte membrane electrode assembly and solid polymer electrolyte fuel cell using same

An electrolyte membrane electrode and solid polymer technology, which is applied in the field of solid polymer electrolyte membrane electrode assemblies and solid polymer electrolyte fuel cells, can solve problems such as electrical instability, hindering the flow of fuel gas or oxidizing gas, etc., and achieve reduction Reduced maintenance frequency such as running costs and replacement, and improved long-term durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

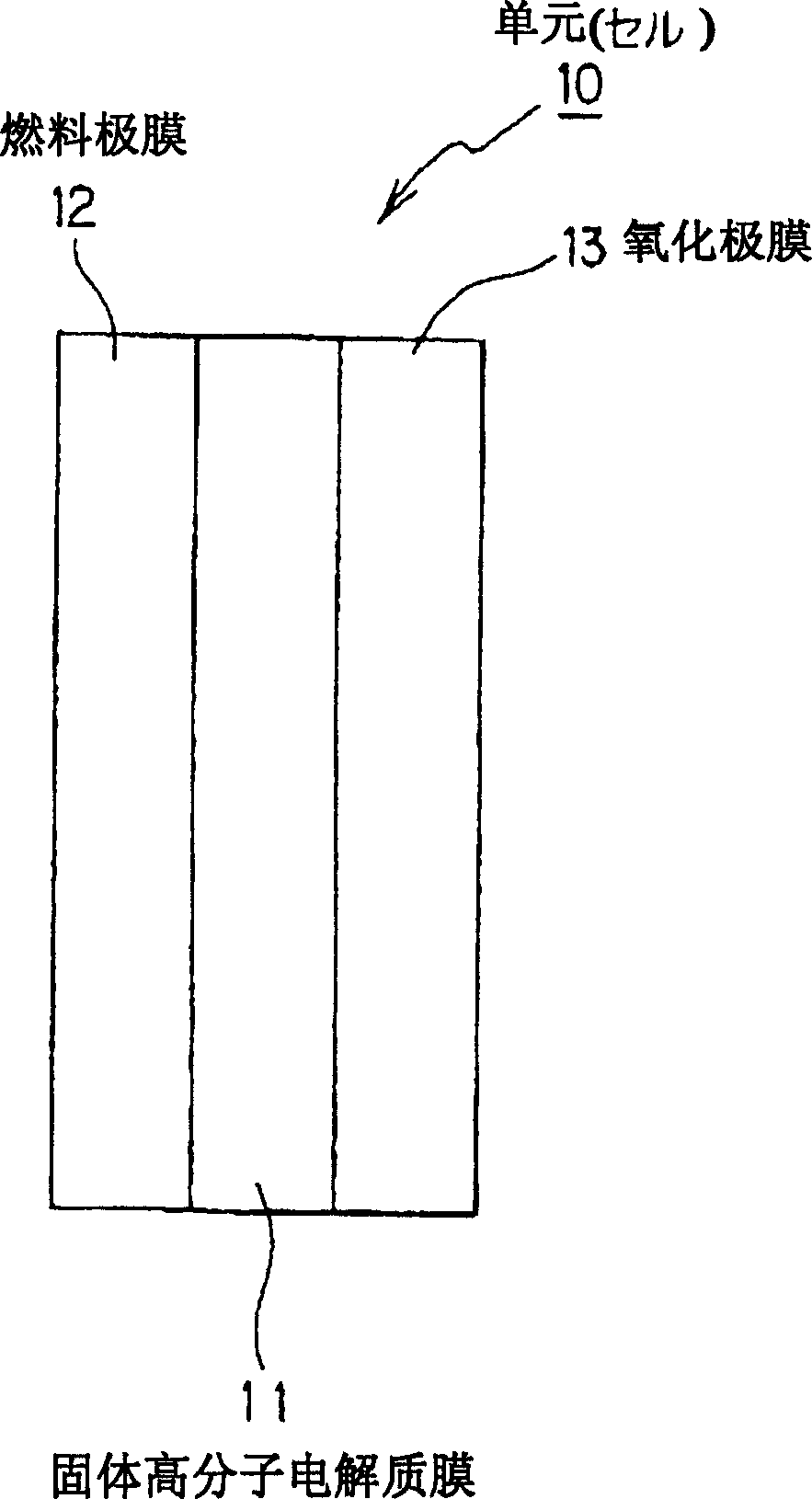

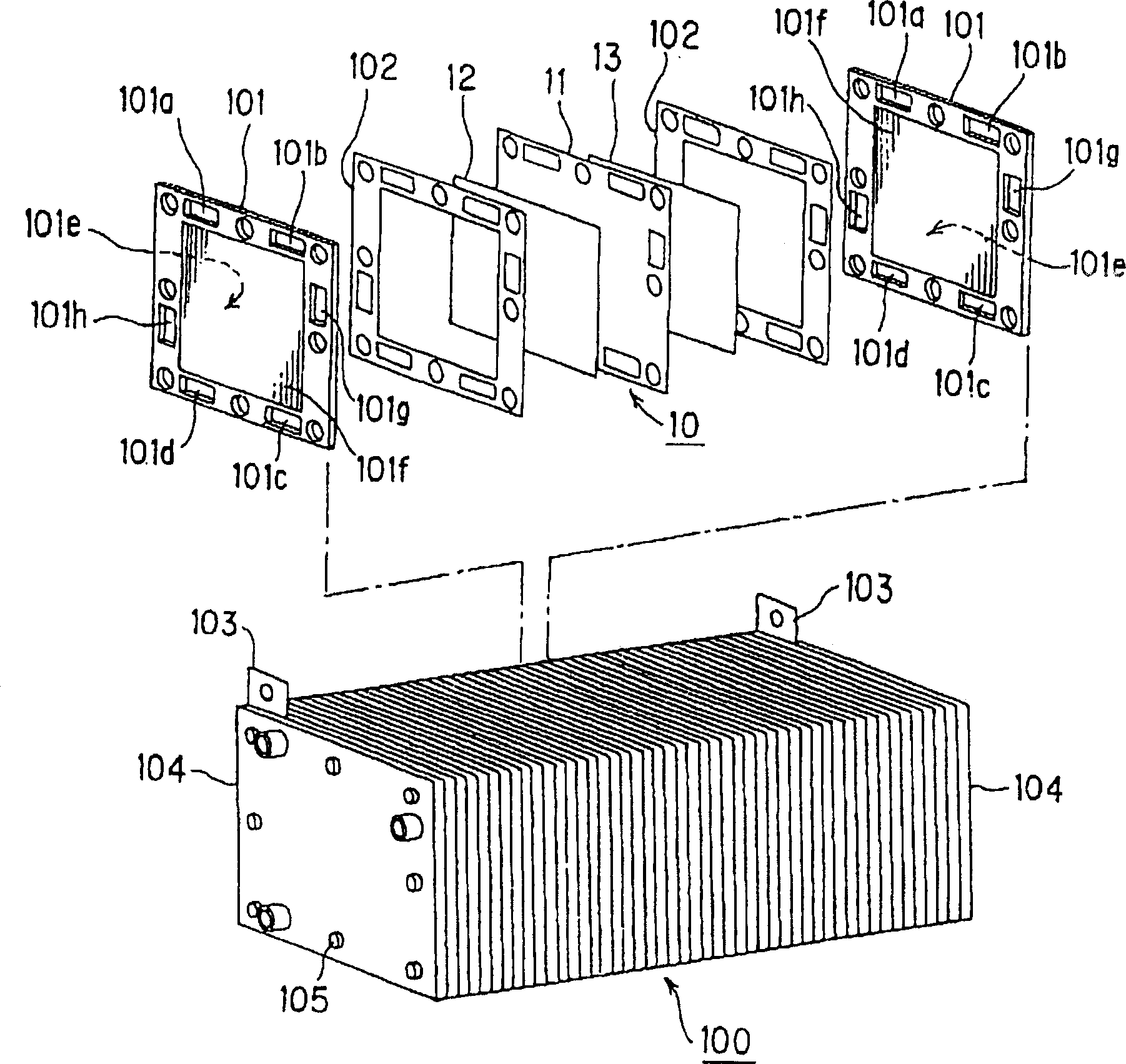

[0046] refer to figure 1 , 2 A first embodiment of the solid polymer electrolyte membrane electrode assembly of the present invention and a solid polymer electrolyte fuel cell using the same will be described. figure 1 is a schematic diagram of the composition of the solid polymer electrolyte membrane electrode assembly, figure 2 It is a schematic configuration diagram of a solid polymer electrolyte fuel cell stack.

[0047] The solid polymer electrolyte membrane electrode assembly that the present invention relates to, such as figure 1 As shown, a solid polymer electrolyte membrane electrode assembly (hereinafter referred to as "unit (cell)") in which a fuel electrode film 12 is provided on one surface of a solid polymer electrolyte membrane 11 and an oxide electrode film 13 is provided on the other surface. ) 10, the solid polymer electrolyte membrane 11 in the cell 10 contains ions of at least one metal selected from the group consisting of Ce, Tl, Mn, Ag, and Yb.

[0...

no. 2 approach

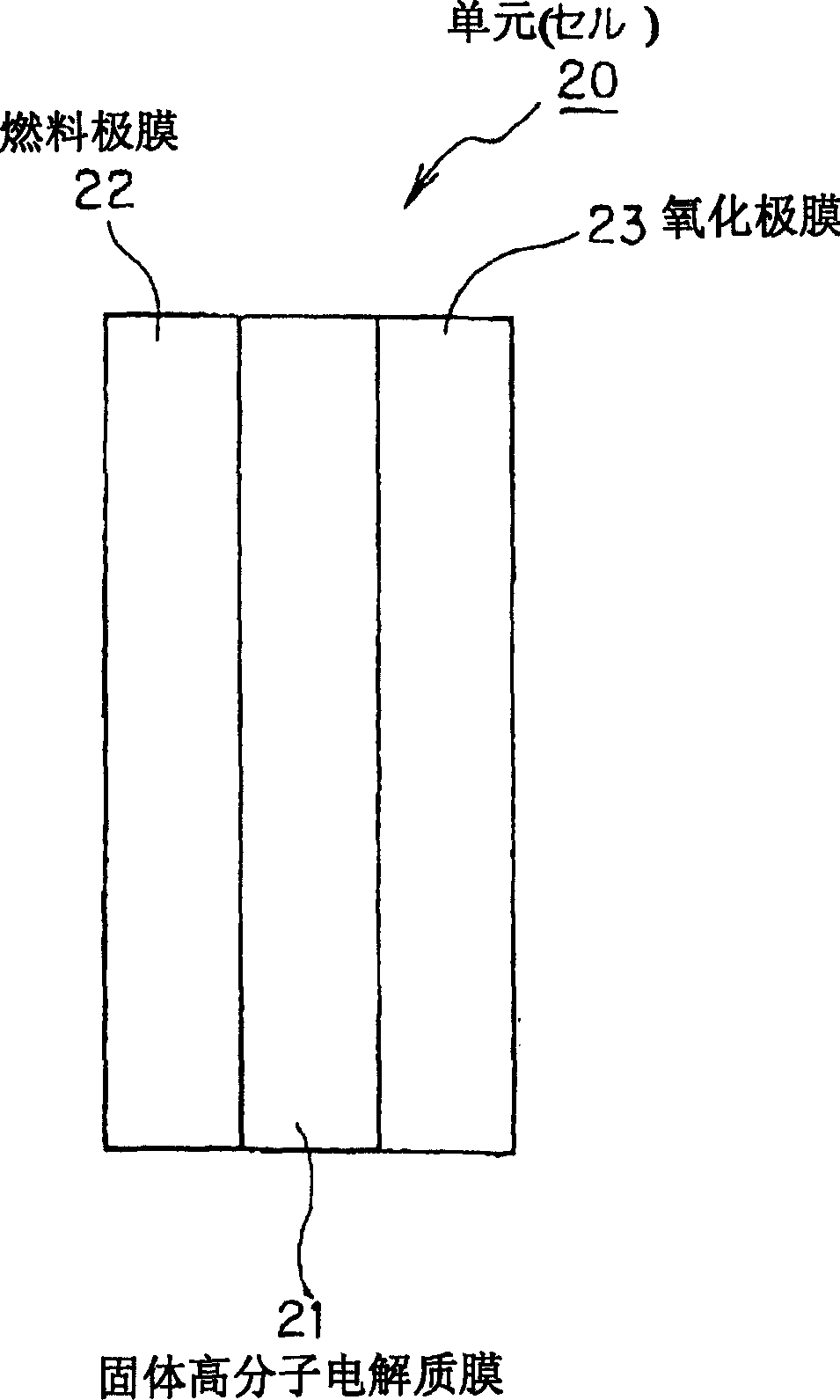

[0070] refer to image 3 A second embodiment of the solid polymer electrolyte membrane electrode assembly of the present invention and a solid polymer electrolyte fuel cell using the same will be described. image 3 It is a schematic diagram of the structure of the solid polymer electrolyte membrane electrode assembly. In addition, the same parts as those of the above-mentioned first embodiment are denoted by the same symbols used in the description of the above-mentioned first embodiment, and the description of the same items as those described in the above-mentioned first embodiment is omitted.

[0071] The solid polymer electrolyte membrane electrode assembly that the present invention relates to, such as image 3 As shown, in the solid polymer electrolyte membrane electrode assembly (unit, cell) 20 in which the fuel electrode film 22 is provided on one surface of the solid polymer electrolyte membrane 21 and the oxide electrode film 23 is provided on the other surface, th...

no. 3 approach

[0087] refer to Figure 4 A third embodiment of the solid polymer electrolyte membrane electrode assembly and the solid polymer electrolyte fuel cell using the same will be described. Figure 4 It is a schematic diagram of the structure of the solid polymer electrolyte membrane electrode assembly. In addition, the same parts as those of the above-mentioned first and second embodiments are denoted by the same symbols used in the description of the above-mentioned first and second embodiments, and the descriptions of the same items as those described in the above-mentioned first and second embodiments are omitted.

[0088] The solid polymer electrolyte membrane electrode assembly related to this embodiment, such as Figure 4 As shown, in the solid polymer electrolyte membrane electrode assembly (unit) 30 in which the fuel electrode film 12 is provided on one surface of the solid polymer electrolyte membrane electrode assembly 21 and the oxide electrode film 13 is provided on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com