Thermal die casting machine

A die-casting machine and casting hole technology, which is applied in the field of hot die-casting machines, can solve problems such as limitations, reduced casting quality, and poor casting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described below with drawings.

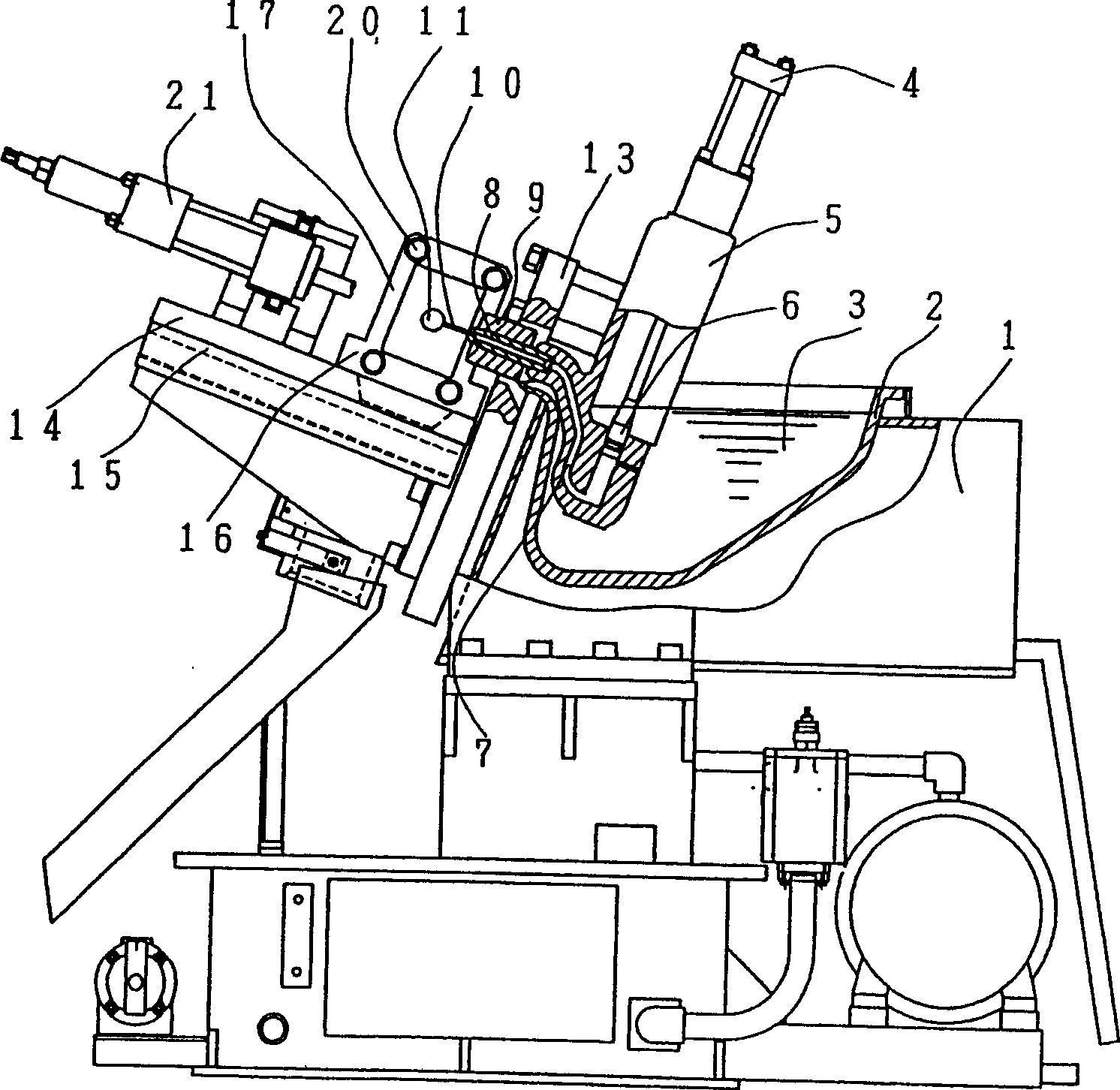

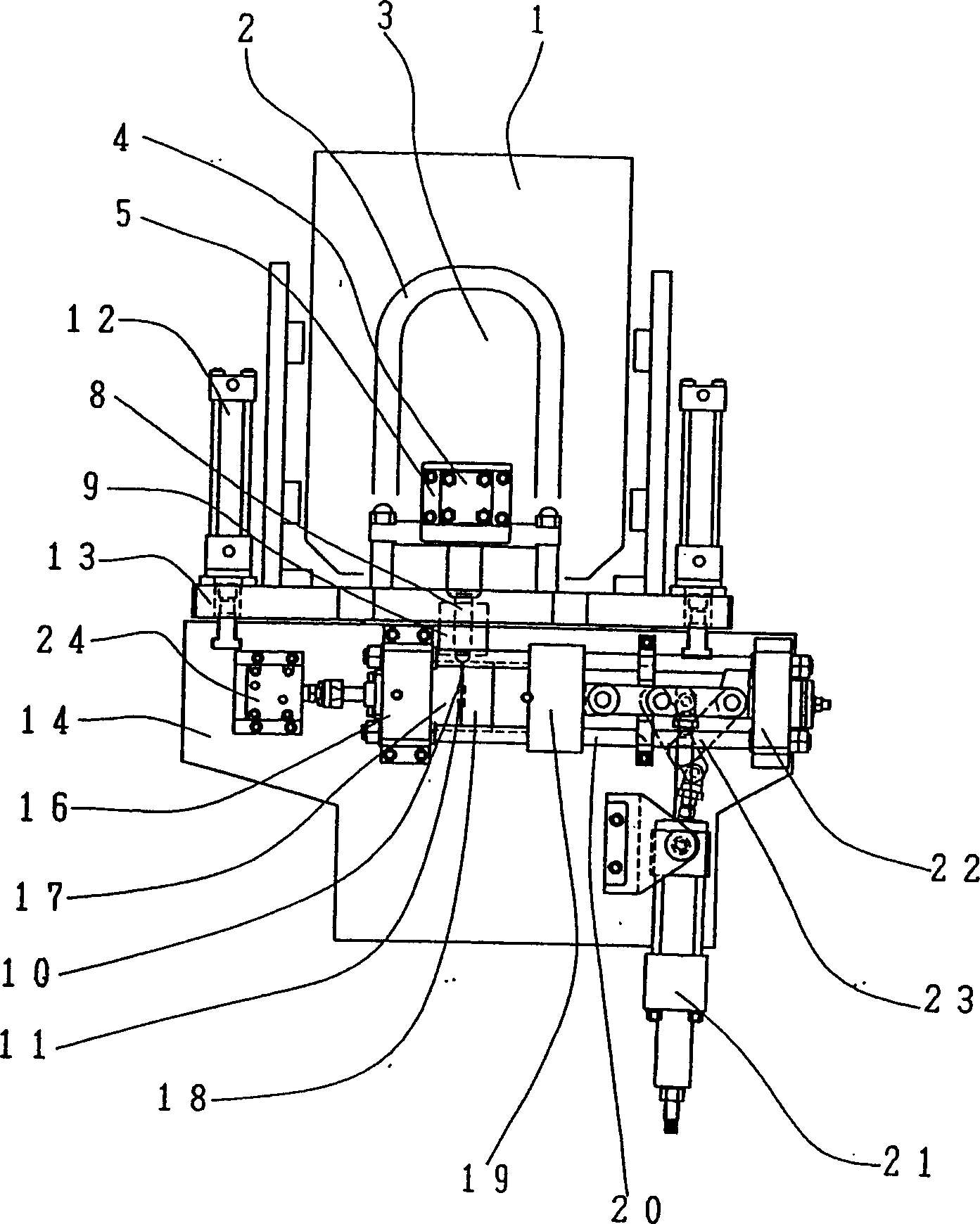

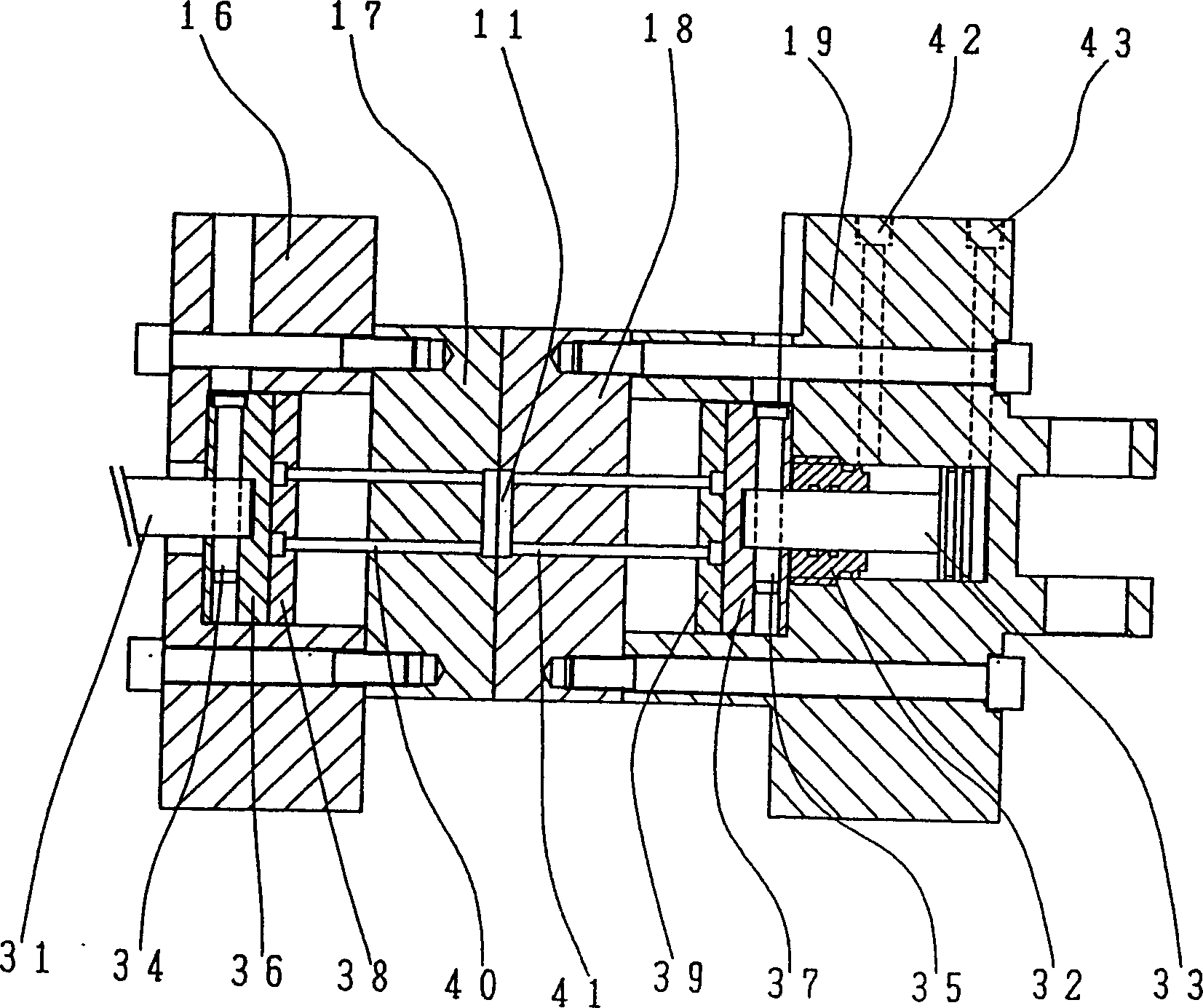

[0038] figure 1 It is a sectional view of a side part of a thermal die casting machine according to an embodiment of the present invention. figure 2 It is another embodiment of the present invention, a top view of a hot combustion chamber die casting machine. figure 1 and figure 2 The hot die-casting machine shown is basically composed of the following two devices, including: an injection device, which can press the molten metal 3 melted in the melting furnace 1 into the casting hole 11 of the metal mold, and an opening Die device can take out its die-casting finished product after the molten metal 3 in casting hole 11 li of metal mold through pressurization is cooled.

[0039] First, the injection device will be described. Using a heater installed in the melting furnace 1 and not shown in the figure to heat the crucible (pot) 2, the metal in the crucible (pot) 2 will be melted into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com