Apple powder making process

A production method, the technology of apple powder, applied in food science and other fields, can solve the problems of nutritional components and flavor damage, poor solubility, loss of attractive color, etc., achieve the effect of small nutritional component loss, low cost, and promote human body absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

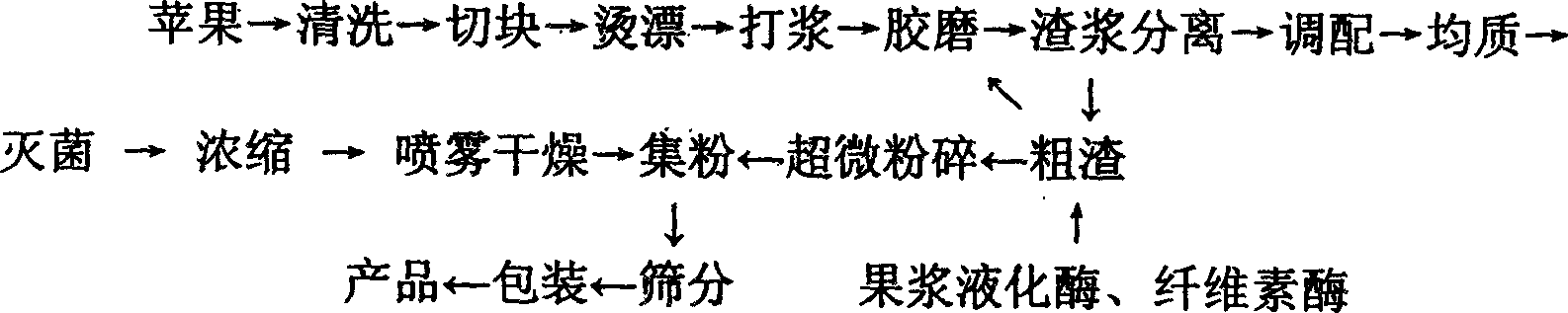

[0025] The present invention is characterized in that it is prepared by using fresh apples as the main raw material and adding isomaltooligosaccharide and resistant starch. The production method of this pure natural apple powder is to use fresh apples as the main raw material, after cleaning, cutting, blanching, beating, rubber milling, secondary treatment, deployment, homogenization, sterilization, concentration, drying, powder collection , screening, packaging, and product warehousing processes to obtain an apple powder product, such as figure 1 shown. From fresh fruit feeding to product delivery, the whole process takes a very short time.

[0026] Specific implementation steps: Select apples with good quality, 80% to 90% maturity, and fresh and insect-free. The raw materials are first soaked in 0.75% hydrochloric acid solution, and then rinsed with clean water to remove most of the pesticide residues and microorganisms on the surface of the apples. Cut the apple into 5cm...

Embodiment 2

[0028] The process conditions were changed as follows: pump 300kg of apple pulp into a jacketed pot with a stirrer, add 12kg of isomaltooligosaccharide and 48kg of resistant starch, add an appropriate amount of water to fully dissolve it, and stir evenly. Low-temperature vacuum concentration is adopted, the concentration condition is: 55° C., the vacuum degree is controlled at 0.07 MPa, and when the solid content reaches 13%, the discharge valve is opened to discharge. A pressure spray dryer is used for drying, and the condition is: the pressure of the high pressure pump is controlled at 14.0MPa. Inlet air temperature: 175°C, exhaust air temperature: 80°C, 33kg of finished product is obtained after drying, and the moisture content of the material is 5%. Other preparation methods are the same as in Example 1.

Embodiment 3

[0030] The process conditions were changed to: pump 300kg of apple pulp into a jacketed pot with a stirrer, add 18kg of isomaltooligosaccharide and 72kg of resistant starch, add an appropriate amount of water to make it just dissolve, and stir evenly. Vacuum cryogenic concentration may not be carried out. Use a spray dryer to dry, and the condition is: the pressure of the high pressure pump is controlled at 12.5MPa. Inlet air temperature: 170°C, exhaust air temperature: 75°C, after drying, 37kg of finished product is obtained, and the moisture content of the material is 5%. Other preparation methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com