Low noise planar transformer

一种变压器、共模噪声的技术,应用在低噪音平面型变压器及其制造领域,能够解决没有披露、降低共模噪声等问题,达到降低共模噪声、降低噪声耦合、提高EMI性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

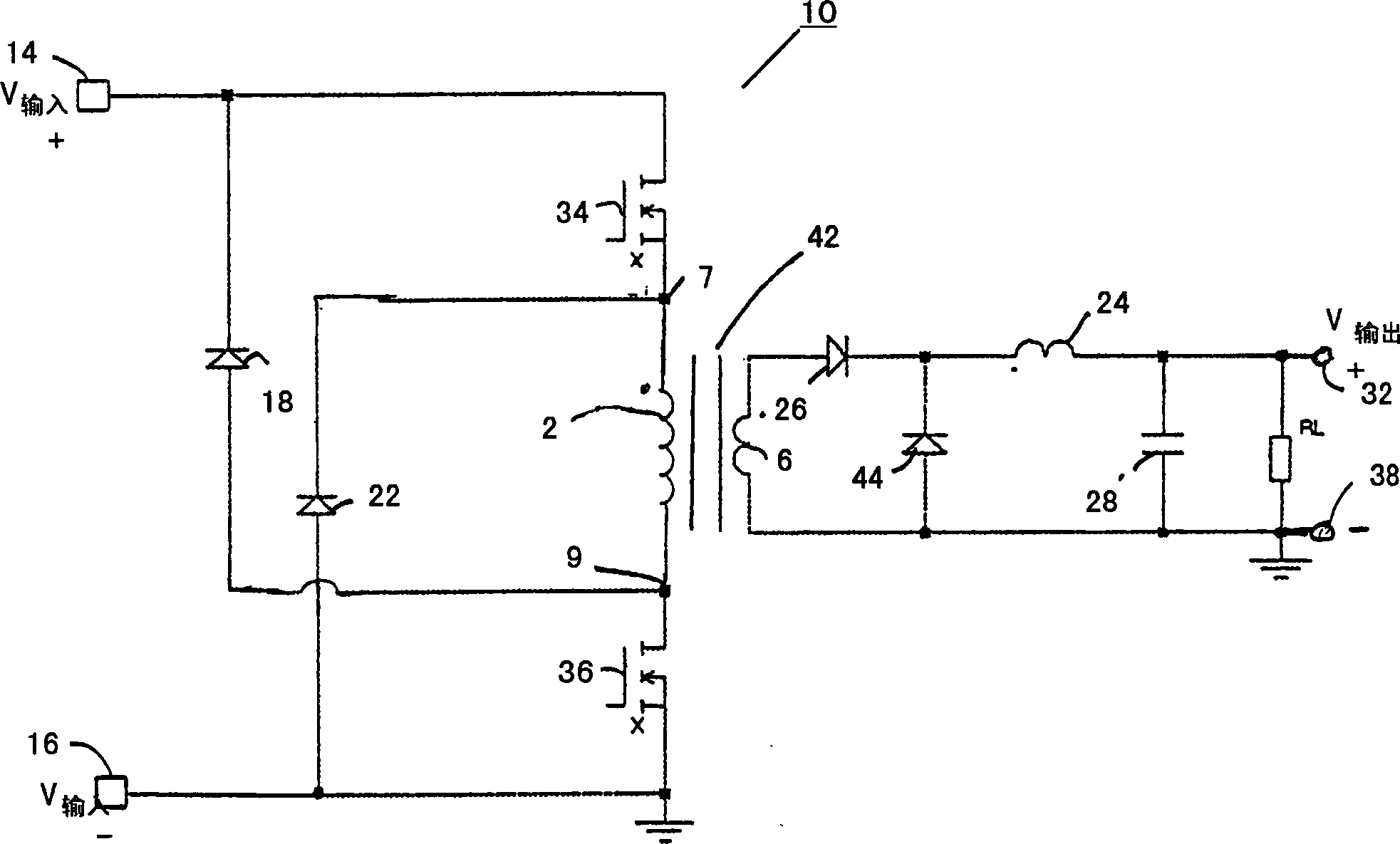

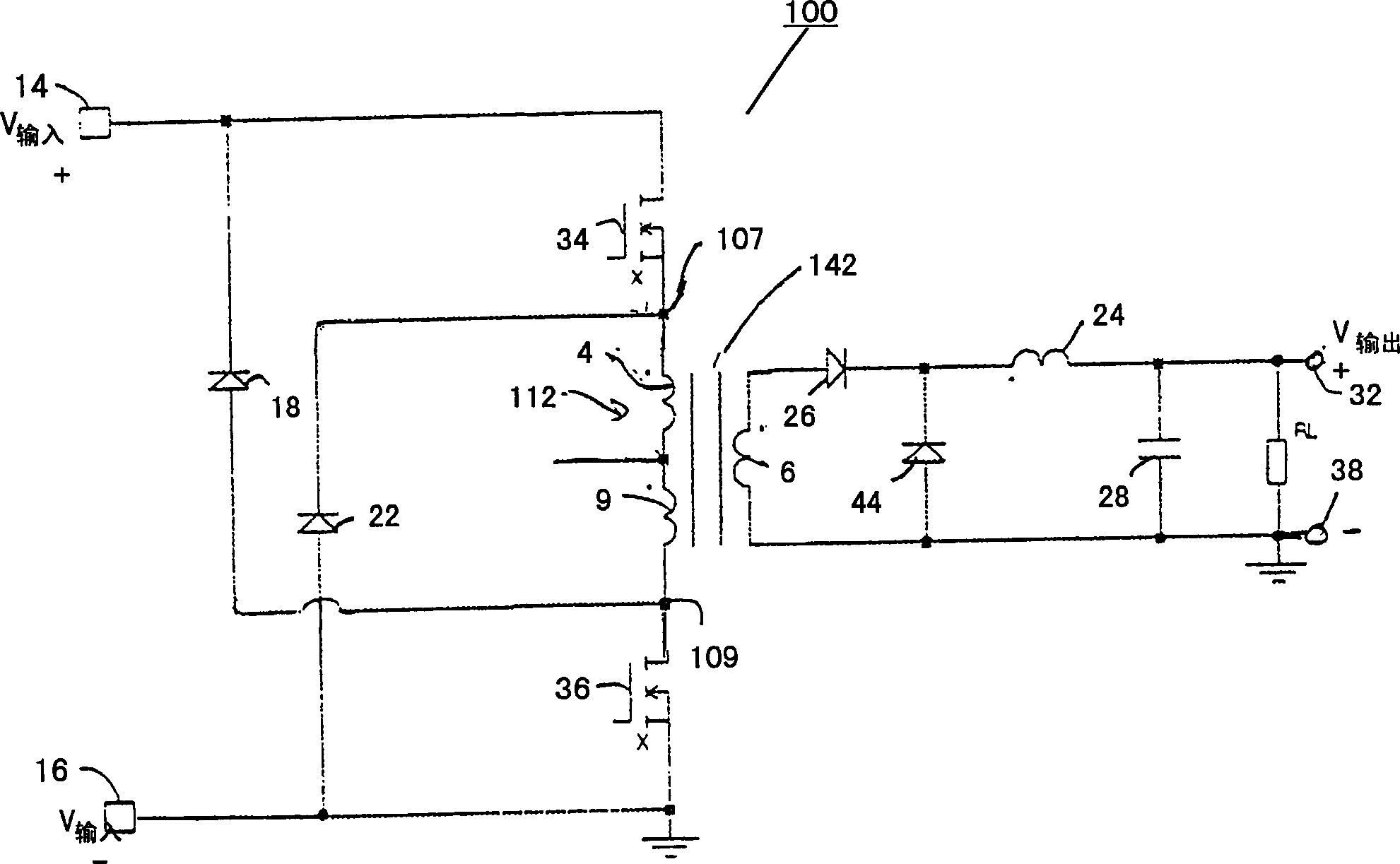

[0039] figure 2 A circuit diagram is shown for a two-switch forward converter 100 having a transformer according to an embodiment of the invention. The converter 100 has an input terminal 14 and an output terminal 32, wherein the input DC voltage V 输入 The ground potential at the relative input terminal 16 is coupled to this input terminal 14, and the output DC voltage V of the converter is set relative to the ground at the output terminal 32 输出 . The converter 100 includes a transformer 142 with a primary winding 112 and a secondary winding 6 . The primary winding 112 is composed of the first winding 4 and the second winding 8 . Each winding has a first end and a second end. The second end of the first winding 4 is connected at node 5 to the first end of the second winding 8 . A power switch 34 is coupled between the first end of the first winding 4 at node 107 and the input terminal 14 . The power switch 36 is connected to the second end of the winding 8 at node 109 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com