Elvator controlled cabinet

A technology for elevator control and control cabinets, applied in elevators, transportation and packaging, etc., which can solve problems such as large inspection area, ground potential cannot be quickly stabilized, and poor electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

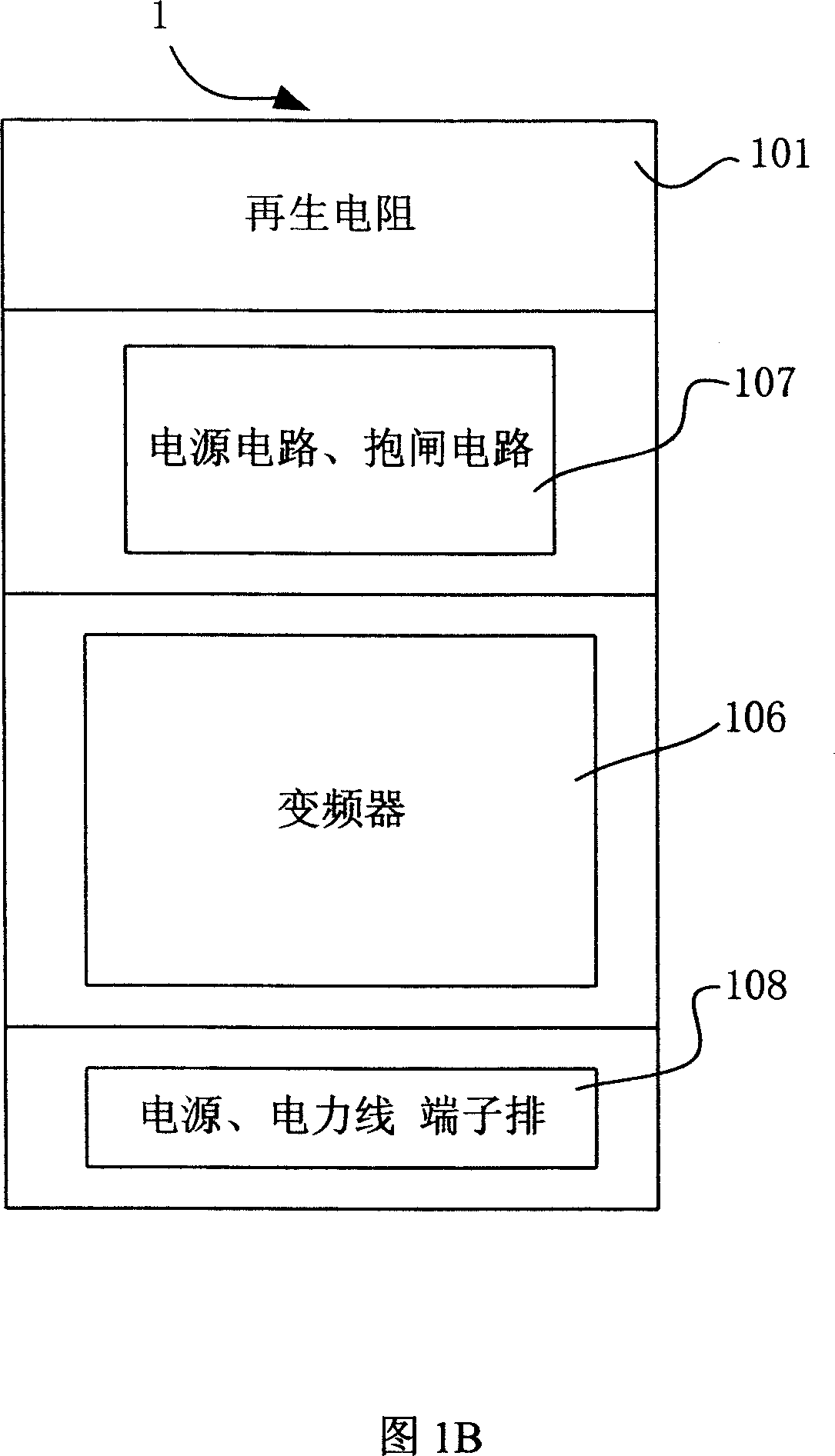

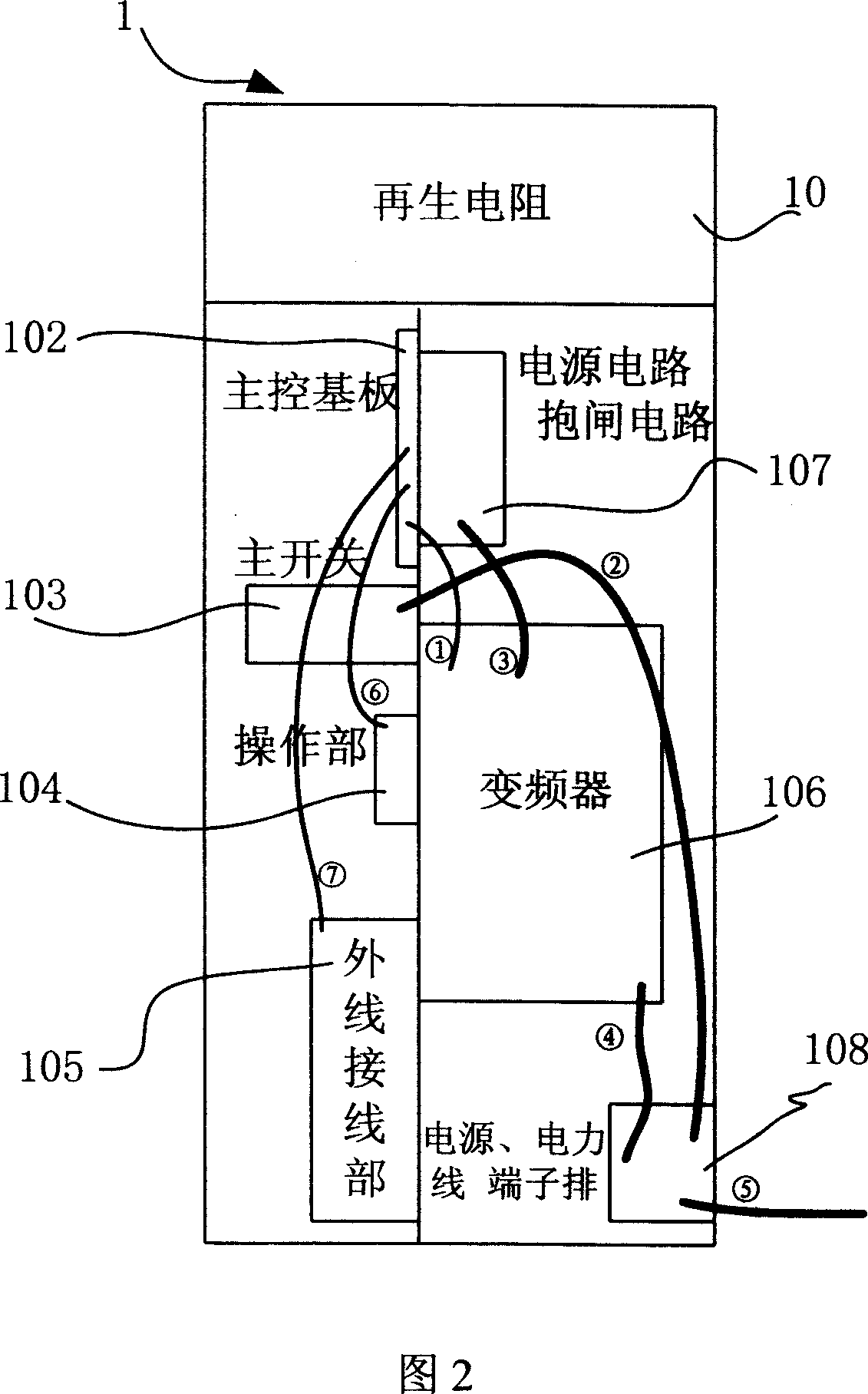

[0017] The technical solution of Embodiment 1 of the present invention will be specifically described below with reference to FIG. 3 . Fig. 3 is a schematic diagram of the main components of the elevator control cabinet according to the first embodiment of the present invention, and is also a front view of the elevator control cabinet according to the first embodiment. Compared with the existing elevator control cabinet, the solution of the first embodiment does not require any circuit modification or addition or deletion of components. It can be seen from Fig. 3 that the main difference between the solution of Embodiment 1 and the existing elevator control cabinet is that the main circuit unit 11 and the control circuit unit 12 in Embodiment 1 are separated from each other, and are respectively arranged in the elevator control cabinet 1. In the two spaces arranged left and right, the two spaces are isolated by the shielding layer 13 to prevent electrical and / or magnetic inter...

Embodiment 2

[0026] The elevator control cabinet of this embodiment is basically the same as that of Embodiment 1, the difference is that the surface of the elevator control cabinet of this embodiment is plated with good conductive materials, such as zinc, copper, gold, silver and the like. From the perspective of cost performance and process realization, it is better to choose galvanized. The existing elevator control cabinet is sprayed with insulating paint, which will affect the performance of the elevator control cabinet against electromagnetic interference. This is because the existing elevator control cabinet is made of materials with insufficient conductivity such as iron. When subjected to sudden electromagnetic interference, it cannot quickly return to the ground potential, so that the ground potential cannot be quickly stabilized. If the surface of the elevator control cabinet is plated with a good conductive material, and the conductivity of the good conductive material is highe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com