Beta zeolite granule possessing multiple grade pore passage and its preparation method

A beta zeolite and pore technology, applied in the field of beta zeolite and its preparation, can solve the problems of difficult filtration, long time, low single-pot yield, etc., and achieve good product repeatability, short crystallization time, and high single-pot yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

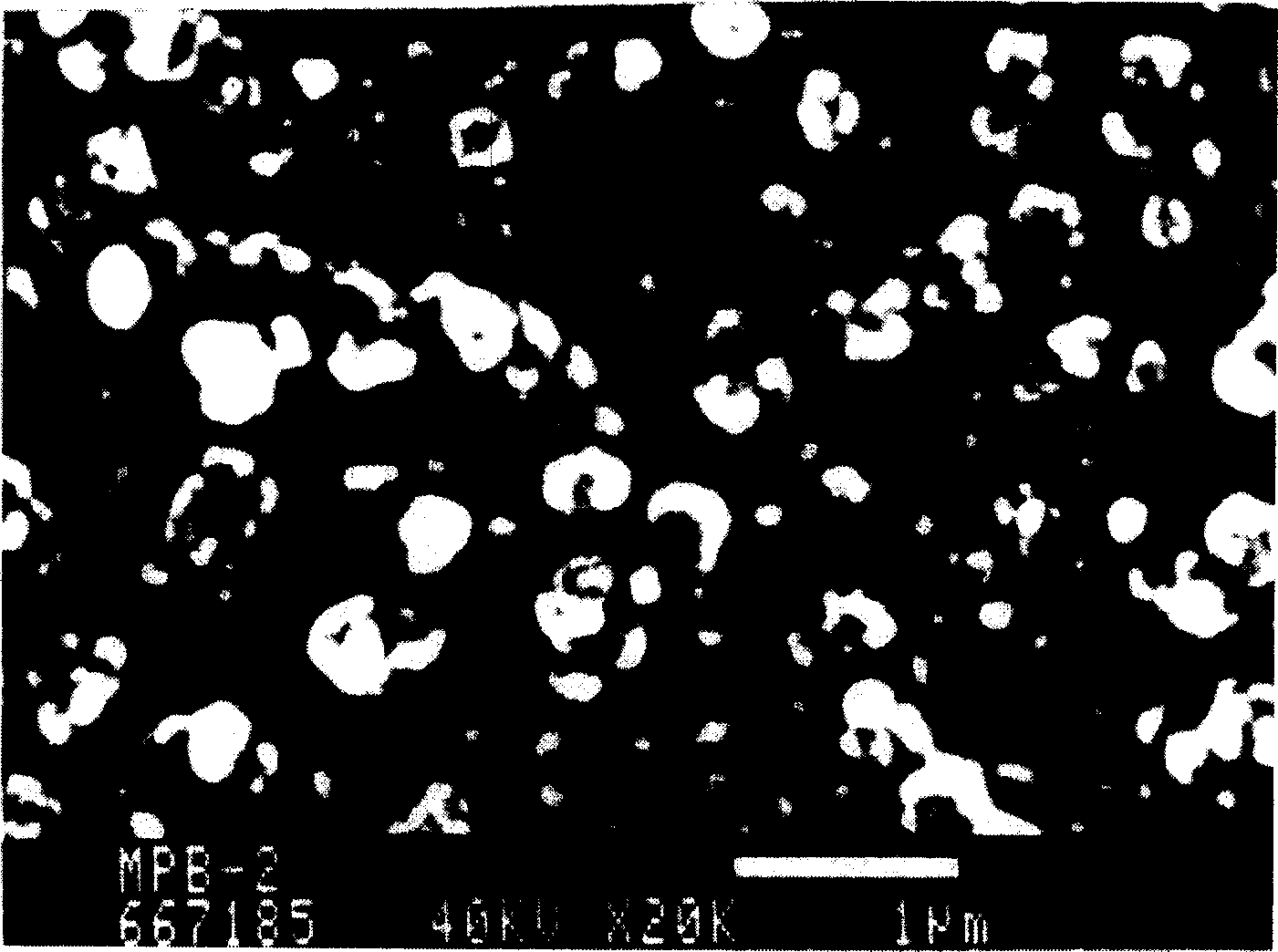

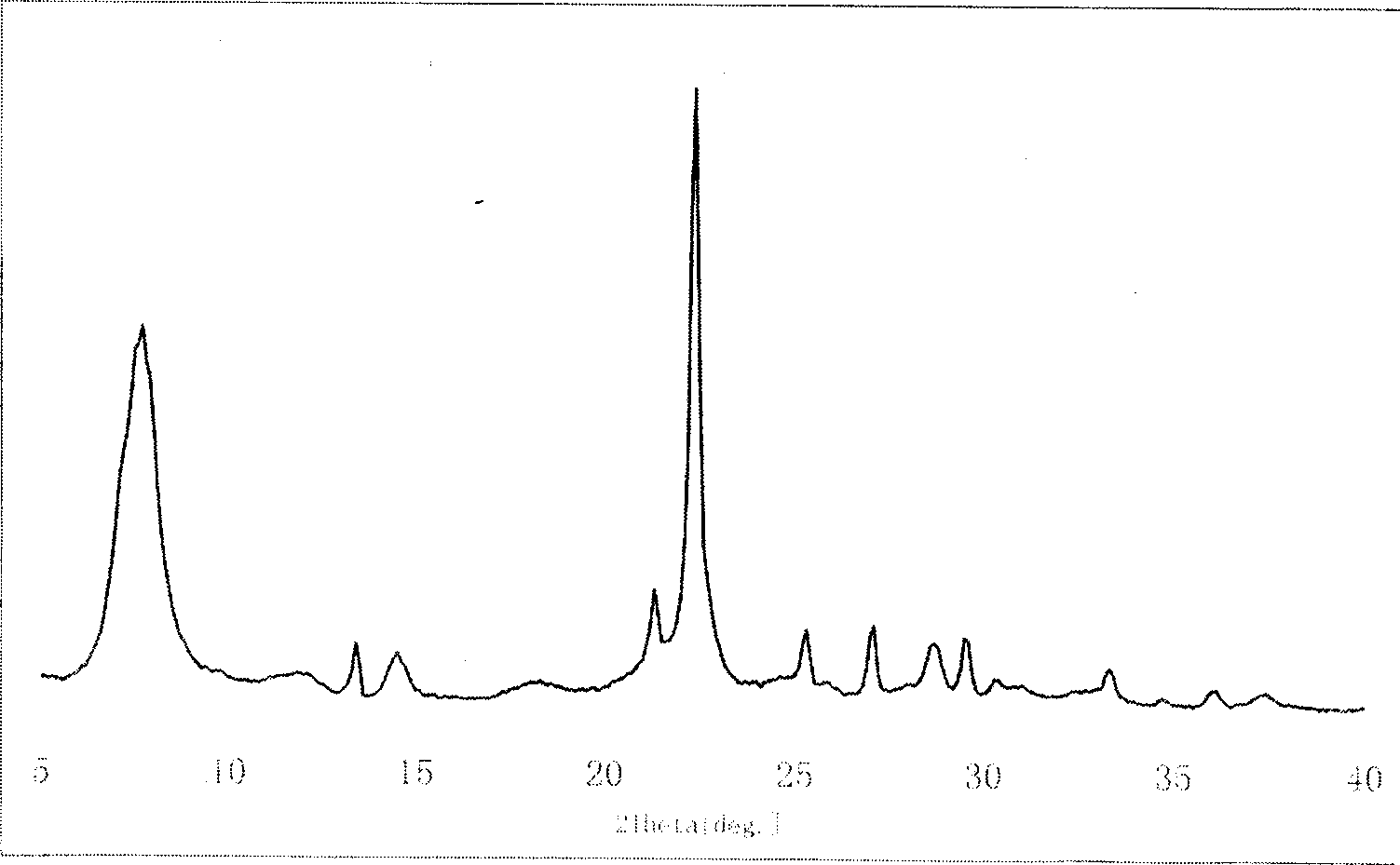

Embodiment 1

[0018] With 78g sodium aluminate (laboratory preparation contains Al 2 o 3 19.9m%, containing Na 2 O 21.44m%), 435g tetraethylammonium hydroxide aqueous solution (the product of industrial production, concentration 1.4N), coarse porous silica gel particle 288g (Qingdao ocean chemical plant production, containing SiO 2 95%) and 120g of purified water are mixed evenly, and reacted in a 2-liter stainless steel reactor at 100°C for 20 hours under sufficient continuous stirring conditions, and then raised to 150°C for crystallization for 40 hours. Ammonium solution, based on the ammonium nitrate concentration in the system being 2 mol / L, was stirred at 95°C for 1 hour and then filtered, and ammonium salt treatment was carried out again according to the above conditions. Then filter, wash with water, dry, remove organic ammonium by three-stage temperature-controlled roasting, dehydrate at a constant temperature of 200°C for 2 hours, decompose organic ammonium at 400°C for 3 hours,...

Embodiment 2

[0020] With 80g sodium aluminate (laboratory preparation contains Al 2 o 3 18.90m%, containing Na 2 O 24.11m%), 382g tetraethylammonium hydroxide aqueous solution (industrial product, concentration 1.55N), coarse porous silica gel particle 280g (Qingdao Ocean Chemical Factory produces SiO 2 95.2m%) and 158g of purified water are mixed evenly. Other conditions were the same as in Example 1 to obtain zeolite beta B-2.

Embodiment 3

[0022] With 80kg sodium aluminate (industrial preparation, containing Al 2 o 3 19.55m%, containing Na 2 O21.17m%), 459kg tetraethylammonium hydroxide (industrial product, concentration 1.35N) coarse-pore silica gel particles 288kg (Qingdao ocean chemical plant production, containing SiO 2 97m%) and 140kg of purified water, after fully mixing, under the continuous stirring condition in 1000 liters of stainless steel crystallization kettles, below with embodiment 1, obtain beta zeolite, B-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com