Turbulent flow spray nozzle

A technology of turbulent nozzles and nozzles, applied in the direction of spraying devices, spraying devices, etc., can solve the problems of high viscosity of coatings and paints, affect the quality of spraying, and affect the progress of work, so as to achieve large spraying work area, improve construction quality, and improve uniformity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

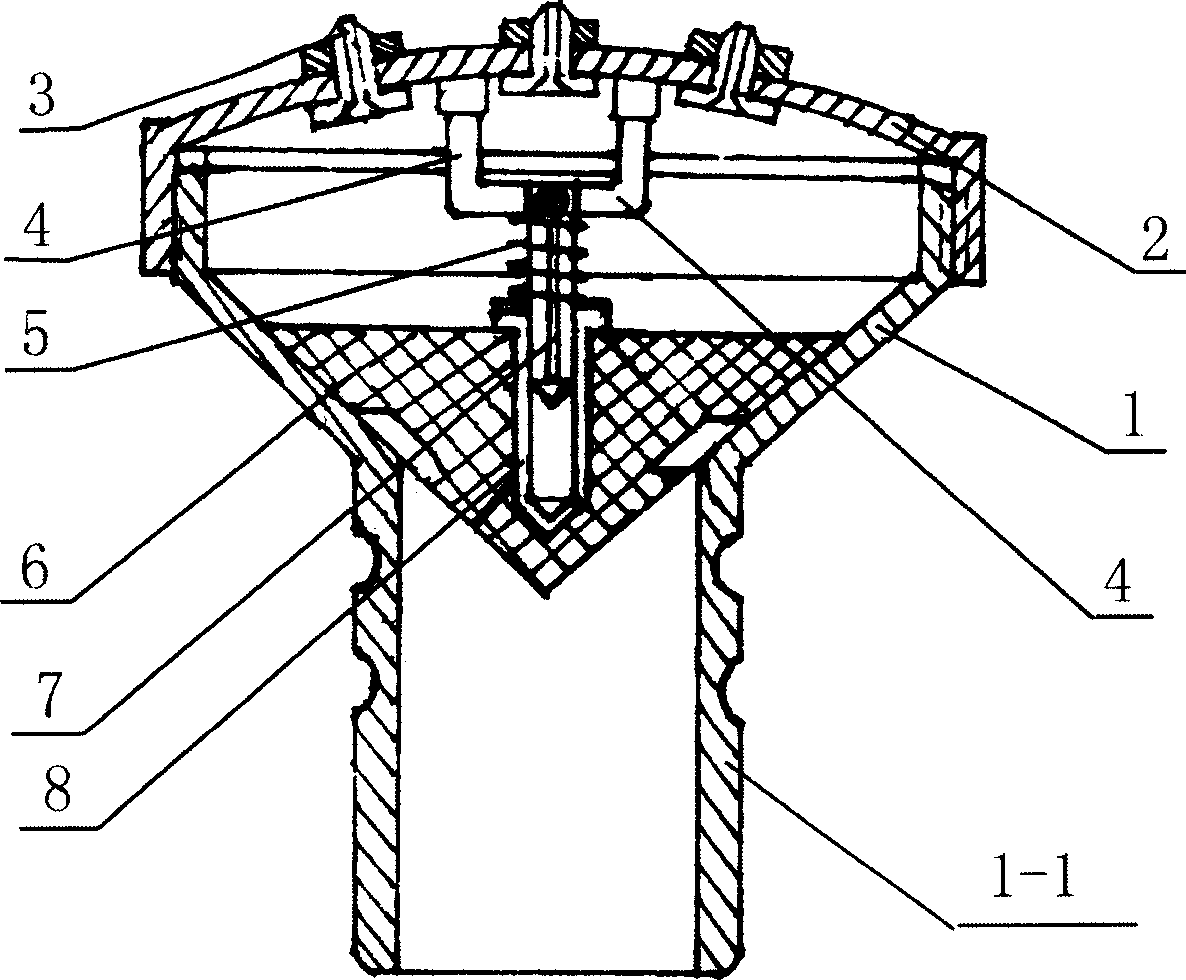

[0016] exist figure 1 In the embodiment, the cavity of the nozzle main body 1 is in the shape of a trumpet with a small inlet and a big outlet, and the bottom of the inlet is connected with a connecting straight pipe 1-1, and the outer wall of the connecting straight pipe 1-1 is formed with a ring-shaped groove, which is beneficial to other nozzles. The machine tool is clamped, and the outlet end of the nozzle main body 1 is connected with the nozzle end cover 2 in a threaded manner. There are many through holes distributed on the end cover 2 of the nozzle, and the nozzle 3 with a stop passes through the through hole on it from the bottom of the end cover 2 of the nozzle, and the nut is screwed into the thread of the exposed nozzle 3 and tightened, and the nozzle 3 is fastened On the nozzle end cover 2, the nozzles 3 can be nozzles with different nozzle sizes.

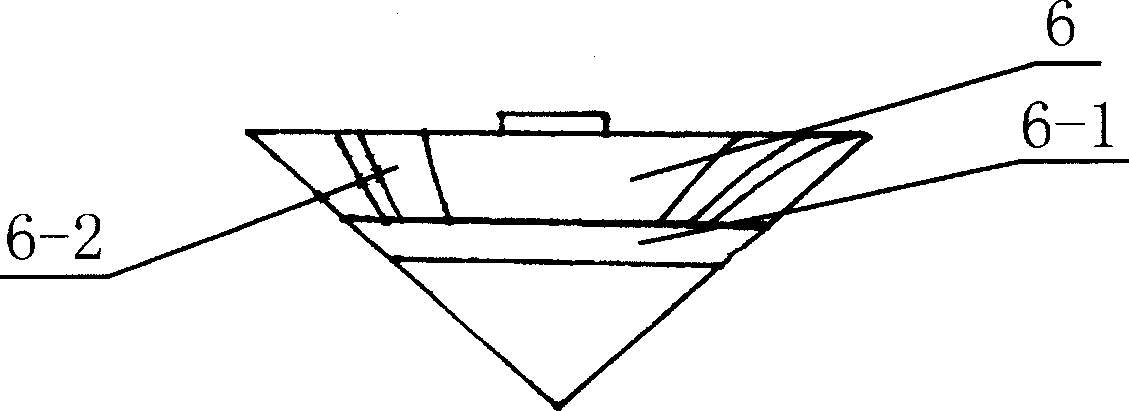

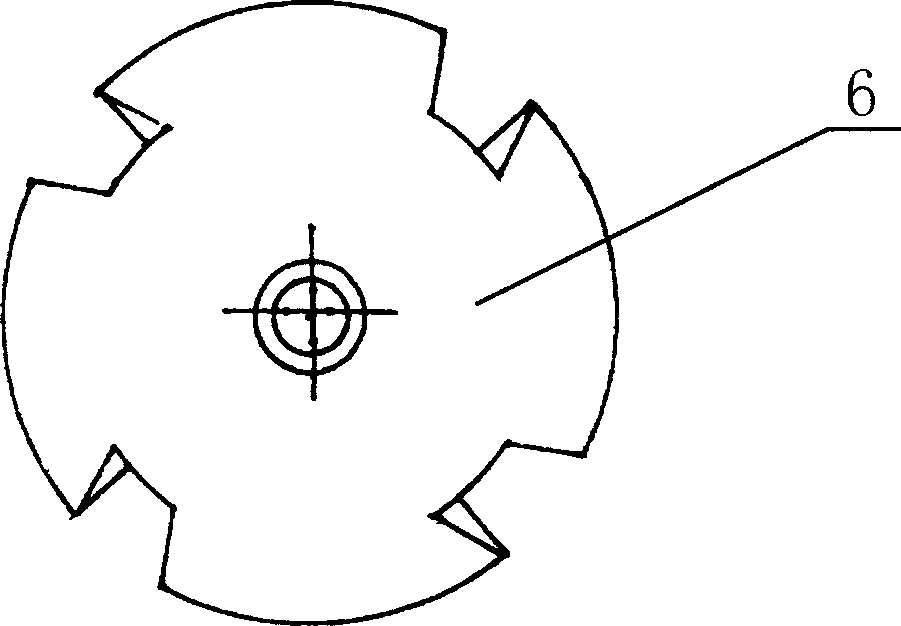

[0017] The trumpet-shaped cavity of the nozzle main body 1 is equipped with a cone 6 that matches it. The cone cone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com