Gas generants

A technology of gas generating agent and oxidizing agent, which is applied in the generation of compressed gas, non-explosive/non-thermal agent components, explosives, etc., and can solve the problems of high cost of tetrazole and expensive compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

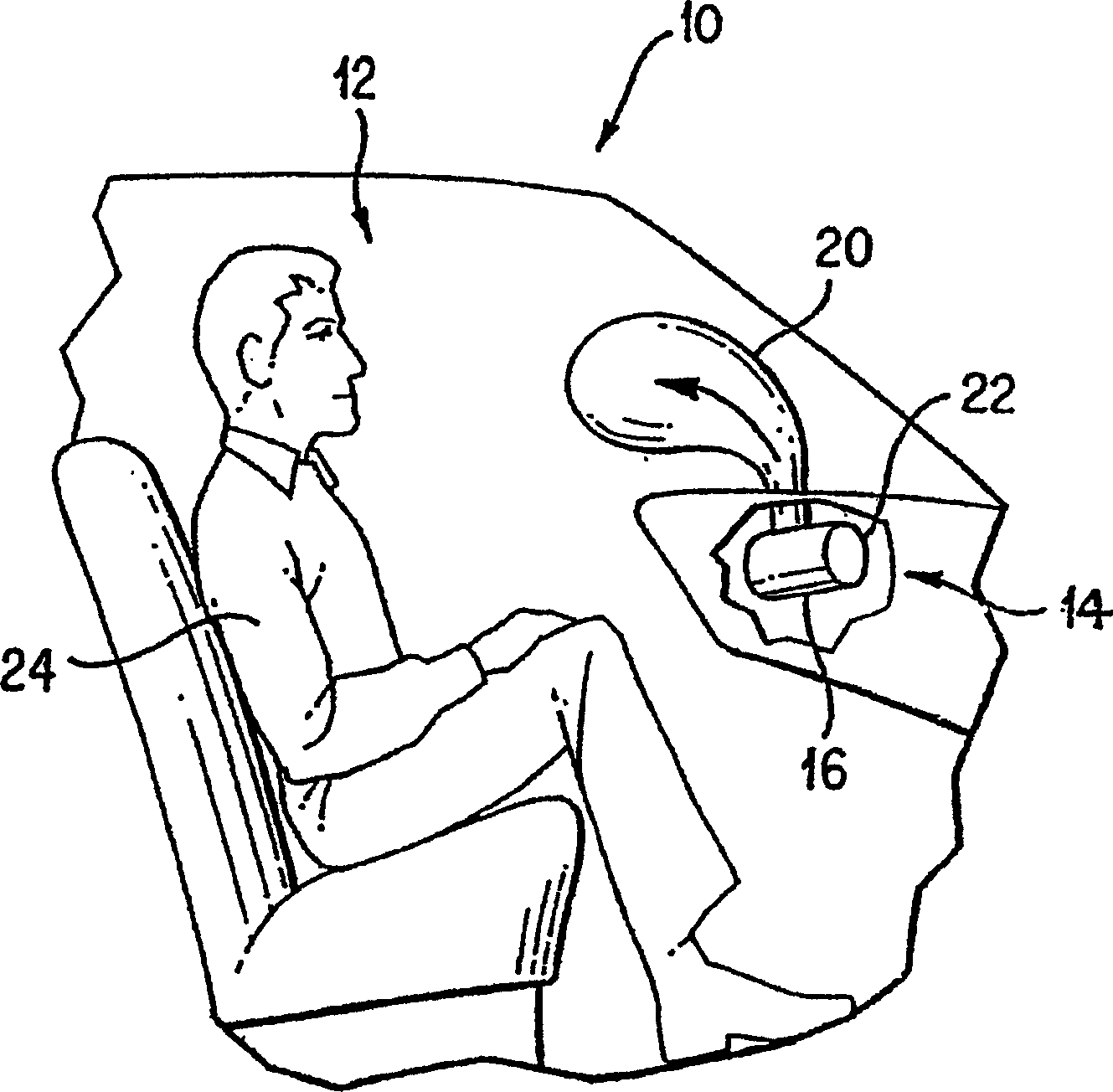

Image

Examples

Embodiment 1

[0061] Embodiment 1 prepares ethylenediamine 5,5'-tetrazolium copper (laboratory scale)

[0062] Bitetrazole dihydrate (50.95 g) was partially dissolved in a beaker containing 200 ml of water. Basic copper carbonate (32.75 g) was added and the temperature of the slurry was equilibrated at 190°F (88°C) and maintained at that temperature until the reaction was complete (approximately 1 hour). Ethylenediamine (35.55 g) was then gradually added to the beaker, immediately forming a complex (100 g).

Embodiment 2

[0063] Embodiment 2 prepares ethylenediamine 5,5'-tetrazolium copper (10 pounds)

[0064]A 10 lb sample of copper ethylenediamine 5,5'-bistetrazole was prepared by filling a spray drying mixing tank with water (9080 ml) and then adding bistetrazole dihydrate (2313.4 g) to partially dissolve it then add basic copper carbonate (1486.85 g) to the spray drying mixing tank, equilibrate the temperature of the slurry at 190°F (88°C), and maintain this temperature until the reaction is complete (approximately 1 hour); then add to the spray drying mixing tank Ethylenediamine was gradually added to form a complex immediately.

Embodiment 3 and comparative example 1、2

[0066] Preparation with basic copper nitrate as oxidant comprises guanidine nitrate and diamine 5,5'-copper tetrazolium as co-fuel (embodiment 3); only comprises guanidine nitrate as fuel (comparative example 1); comprises guanidine nitrate and di( Ethylenediamine) 5,5'-bitetrazolium copper as the gas generant composition of the co-fuel (Comparative Example 2), as shown in Table 2 below. The values in Table 2 all refer to the weight percentage relative to the composition.

[0067] Element

Example 3

Comparative example 1

Comparative example 2

Basic copper nitrate

60.34

47.33

51.05

Guanidine nitrate

28.16

51.17

37.45

Aluminum oxide

1.50

1.50

1.50

Bis(ethylenediamine) 5,5'

-copper tetrazolium

10.00

-

-

Diazepam 5,5'-dinitrogen

-

-

10.00

[0068] Then, the gas generant compositions in Example 3 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com