Stranded copper-plated aluminum cable, and method for its fabrication

By covering the aluminum core conductor with a copper intermediate layer and forming a nickel surface layer of appropriate thickness, the problem of limited application of aluminum conductors in the aviation industry is solved, and high-efficiency conductivity and corrosion resistance under aggressive conditions are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

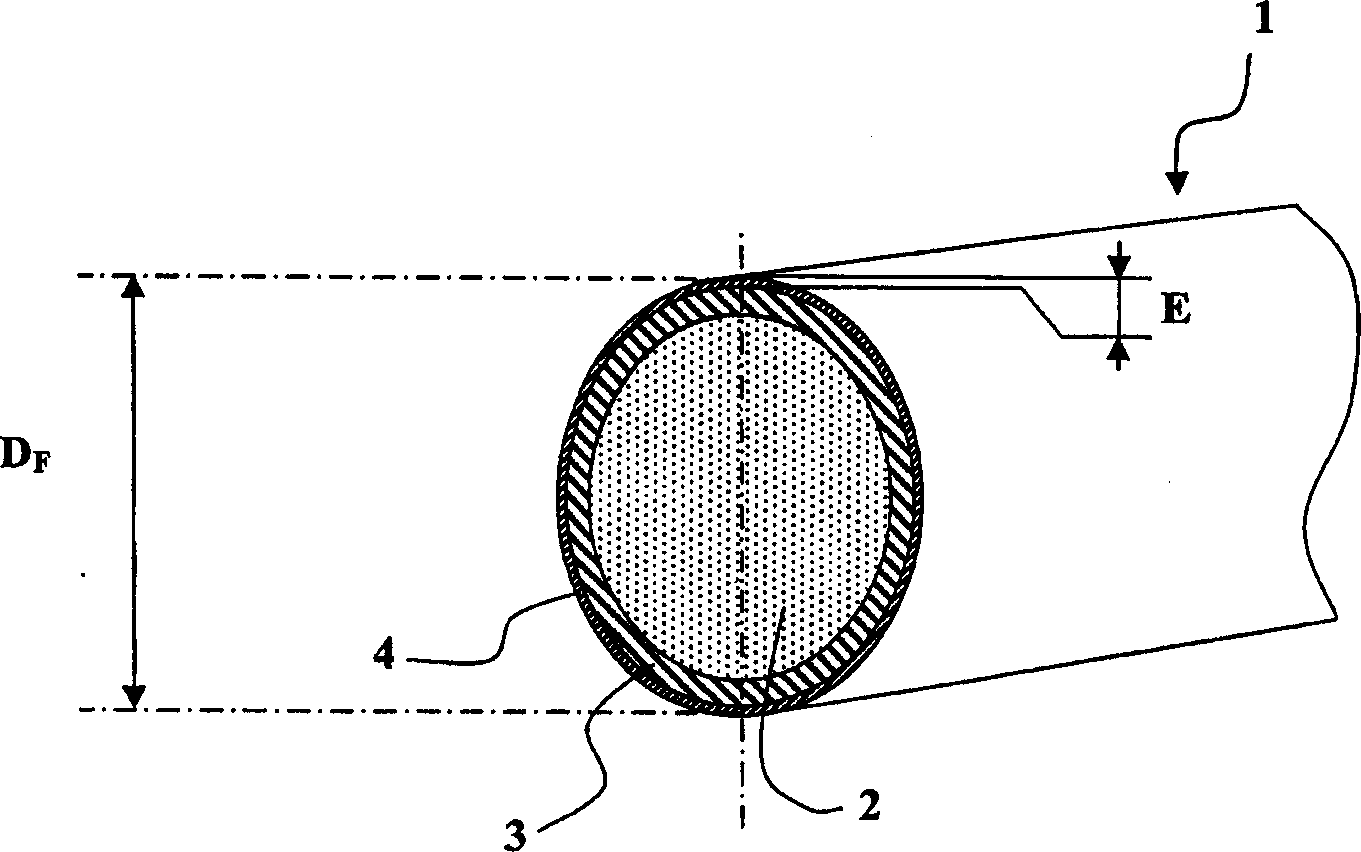

[0061] First refer to figure 1 , which shows the structure of one embodiment of the conductive wire 1 of the present invention. An aluminum core 2 covered with a copper intermediate layer 3 covered with a nickel surface layer 4 can be seen.

[0062] Aluminum constituting the core 2 may be pure aluminum or an aluminum alloy. A 99.5% aluminum alloy containing at most 0.10% silicon and at most 0.40% iron is preferred.

[0063] In aerospace or automotive industry applications, the wire may have a final overall diameter DF of about 0.51 mm to about 0.20 mm. However, other diameter values may also be used, depending on desired properties.

[0064] The copper interlayer 3 can advantageously represent 15% of the volume of the wire. This produces a wire with the following properties: a density of about 3.60 kg / dm3 at 20°C and a resistivity of 2.78×10 -8 Ohmmeter, conductivity 60% to 64% IACS - typically 62% IACS, yield point 138 N / mm2 and minimum elongation 6%.

[0065] In orde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com