Light-emitting diode device and production method thereof

A technology of light-emitting diodes and devices, which is applied to semiconductor devices, electrical components, circuits, etc., and can solve problems such as blocking and emission efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

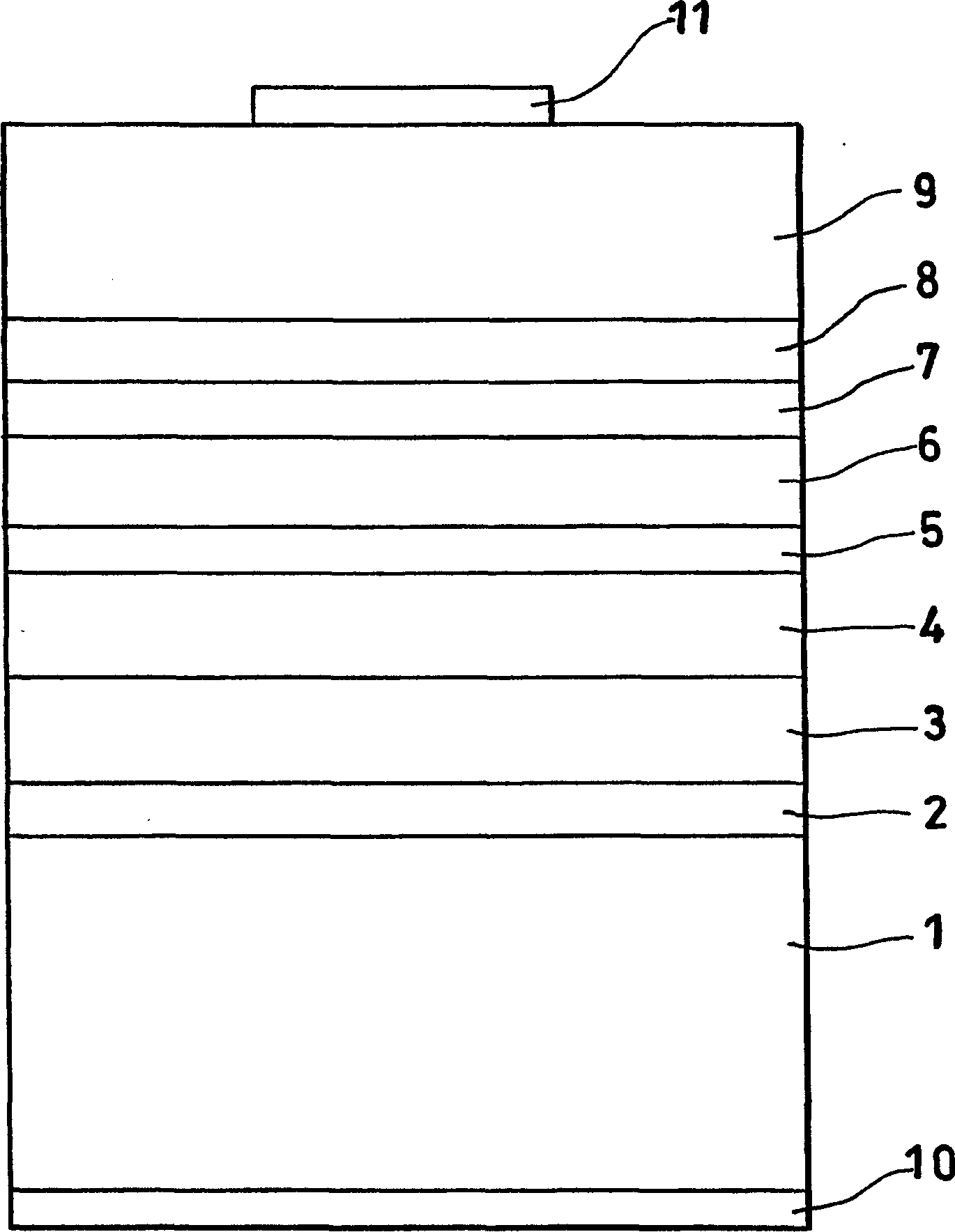

[0068] figure 1 is a schematic cross-sectional view showing one embodiment of a double heterostructure light emitting diode (LED) device with an AlGaInP active layer according to the present invention. In this embodiment, a buffer layer 2, a reflective layer 3, an n-type cladding layer 4, a first undoped AlInP layer 5, an active layer 6, a second undoped AlInP layer 7, p-type intermediate layer 8 and window layer 9 , while providing n-electrode 10 on the back surface of substrate 1 and p-electrode 11 on the front surface of window layer 9 .

[0069] The substrate used in this embodiment was a silicon (Si) doped gallium arsenide (GaAs) substrate (15° offset from (100)). On the substrate, by using trimethylgallium (Ga(CH 3 ) 3 ), trimethylindium (In(CH 3 ) 3 ), trimethylaluminum (Al(CH 3 ) 3 ), dimethyl zinc (Zn(CH 3 ) 2 ), disilane (Si 2 h 6 ), arsenic trihydride (AsH 3 OO) and phosphine (PH 3 ) to form the layers listed in Table 1 below. Note that during film fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com